The climate in coastal areas is unique and is constantly influenced by the marine environment. Factors such as high temperature and humidity, salt spray corrosion, and strong winds can also seriously affect the quality and service life of buildings. Therefore, when applying aluminum zinc metal materials in coastal areas, the following precautions should be taken.

Firstly, choose materials that are suitable for the seaside environment. Aluminum zinc plates have excellent corrosion resistance and can maintain a long-term service life in seaside environments. When selecting materials, it is necessary to choose high-zinc aluminum zinc plates and ensure that the material standards comply with national standards.

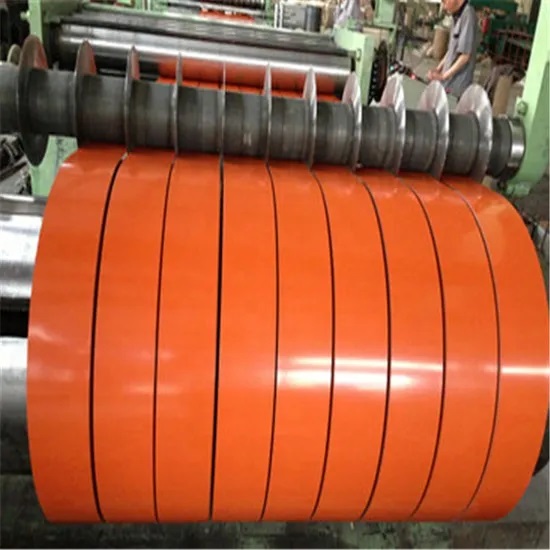

Secondly, for purchased aluminum zinc plates, surface treatment is required before applying. The surface treatment of aluminum zinc plated plates includes processes such as anti-finger print, painting and spraying, which can improve the oxidation resistance and surface hardness of the plates.

Thirdly, attention should be paid to the installation and maintenance of materials. The installation of aluminum zinc plates requires a professional construction team to ensure that the installation quality meets national standards, and special attention should be paid to the waterproofing of the gaps and seals between the plates. During the installation process, it is necessary to pay attention to changes in the environment and weather, and take timely protective measures according to needs.

Regular maintenance is required during the use of aluminum zinc plates. Dust and rainwater can accumulate on the surface of the board, affecting its luster and aesthetics, as well as reducing its corrosion resistance. Therefore, it is necessary to wipe the board surface with a cloth to keep it clean. In addition, in seaside environments, anti-corrosion treatment is important, and regular protective work is also necessary, such as applying specialized anti-corrosion paint. Regular inspection of the coating for damage or corrosion, as well as the tightening of screws, is also necessary.

Although aluminum zinc plates have high corrosion resistance, if not regularly maintained, aluminum zinc plates may lose their corrosion resistance due to holes and other reasons, thereby shortening their service life.

In summary, to use aluminum zinc plates well, it is necessary to choose high-quality materials, pay attention to surface treatment, correct installation, regular maintenance, and pay attention to service life. These precautions ensure that aluminum zinc plates can be used stably in coastal areas for a long time.