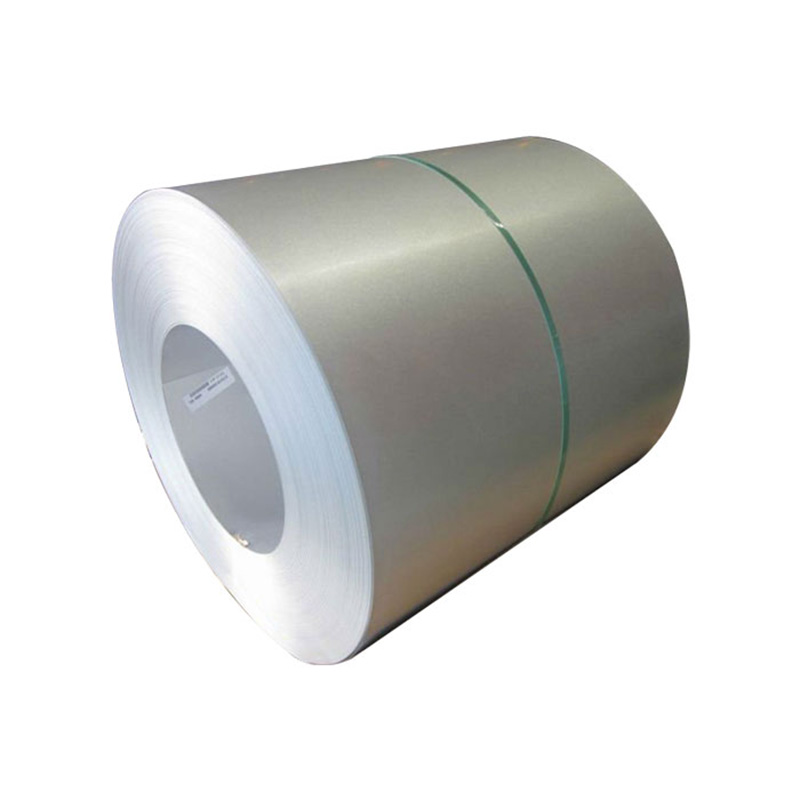

Hot Dipped Galvalume Steel Coil

Hot dipped galvalume steel coil is an alloy steel plate composed of 55% Aluminum, 43.5% Zinc,1.5% Silicon.

Hot dipped galvalume steel coil demonstrates stable anti-rust and anti-corrosion ability in various acid and alkaline, humid, and rainy environmental tests. So, galvalume steel coil has a wide range of applications in the industry.

The manufacturing process of Galvalume steel involves coating a cold-rolled steel substrate with a mixture of aluminum, zinc, and silicon. This coating is applied through a hot-dip process, where the steel coil is immersed in a bath of molten alloy.

Hot dipped galvalume steel coil have a smooth and silver-color spangle surface. The special aluminum and zinc coating structure makes it have excellent corrosion resistance, good heat resistance, good adhesion between the coating and the paint film, good processing performance of punching, cutting, welding, etc.

| Hot Dipped Galvalume Steel Coil | |

| Standard | JIS G3321, EN 10215, ASTM 792 |

| Grade | SGLCC, SGLCH |

| DX51D+AZ,DX52D+AZ, DX53D+AZ | |

| G300 G500 | |

| Alu-zinc Composition | 55% Aluminum, 43.5% Zinc,1.5% Silicon |

| Alu-zinc Coating | 40-150G/M2 |

| Surface Treatment | Chromated Passivation, Oiled, No-oiled, Anti-Finger Print |

| Hardness | Softy, Semi Hard, Full Hard, G550 |

| Thickness | 0.12-4.00MM |

| Width | 20-1500MM |

| Coil Weight | 3-5MT/Coil or Customized |

| Coil Inner Diameter | 508MM or 610MM |

| Package | Standard Seaworthy Exporting Packing |

| MOQ | 25MT |

Hot dipped galvalume steel coil have the following advantaged features:

1.Heat reflectivity

Hot dipped galvalume steel sheet in coil have a high heat reflectivity, twice than the galvanized steel sheet, used as a material for heat insulation.

2.Heat resistance

Aluminum-zinc steel plate can withstand high temperatures of more than 300 degrees Celsius, which are widely applied in chimney pipes, ovens, illuminators and fluorescent lampshades.

3.Corrosion resistance

The corrosion resistance are effected by the protective function of aluminum. When zinc break, aluminum will create a dense layer of aluminum oxide, which prevents corrosion-resistant substances from further corroding the interior.

4.Economic practicality

The area of the galvalume steel plate is more than 3% larger than that of the galvanized steel sheet with the same weight and the same coating thickness because the density of 55% AL-Zn is lower than that of zinc.

5.Easy to paint

The aluminum-zinc plate have excellent adhesion, which can be painted without pre-treatment.

6. Formablity

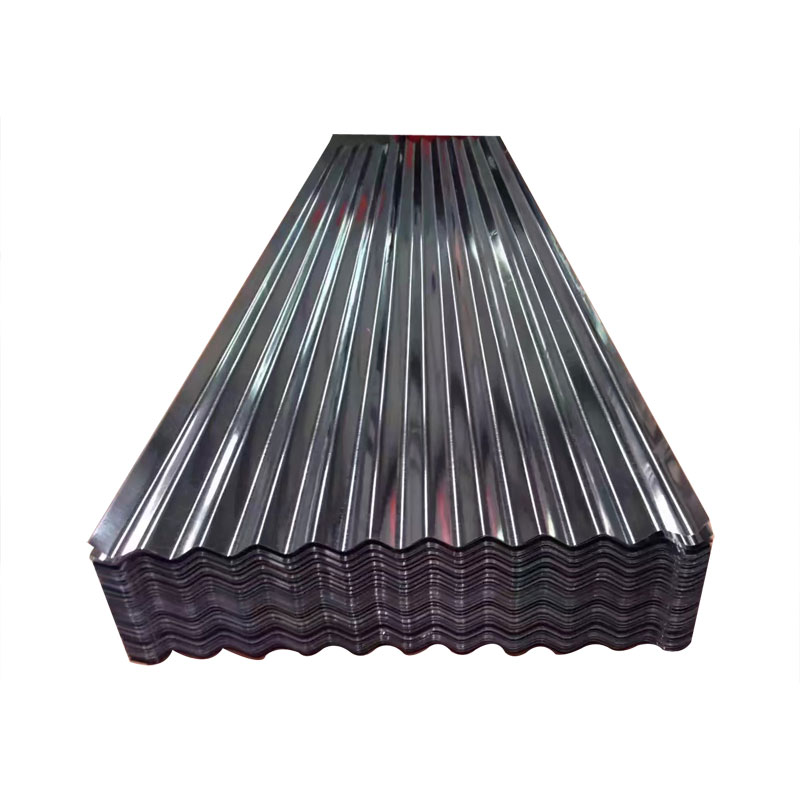

The Galvalume Steel Coil have excellent formability, which can be painted without pre-treatment allowing it to be shaped and processed in various ways without compromising its corrosion-resistant properties, such as Galvalume Corrugated Roofing Sheet, Galvalume Steel Strip, Galvalume Steel C Purlin, Appliance, Waterproof Gutter etc.

Hot Dipped Galvalume steel coil have other similar name Aluzinc ir Zincalume steel coil, Galvalume Coating acts as a barrier against corrosion, and the sacrificial nature of zinc further enhances the steel’s durability.