To begin with

The steel enterprise has seen momentous beforehand in manufacturing techniques, providing a wide array of products for various applications. Among these, galvanized steel strip, galvalume steel strip, aluzinc steel strip, prepainted galvanized roofing sheet, and prepainted galvalume roofing sheet are some of the most commonly used materials in construction, automotive, and manufacturing industries.

In this blog post, we will look into the characteristics, differences, and applications of these materials to help you understand their benefits and guide you in selecting the right one for your needs.

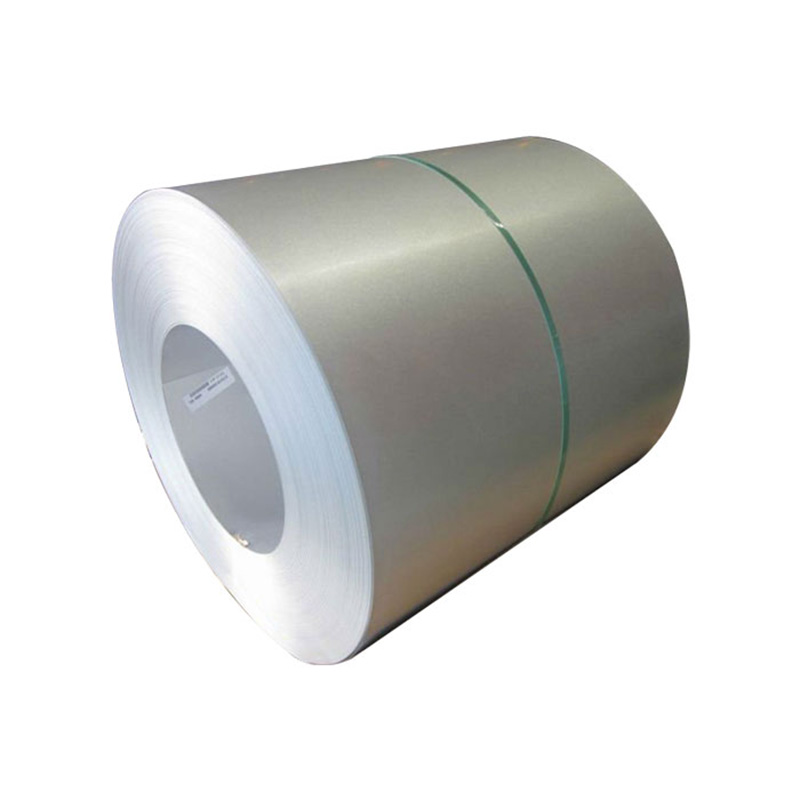

Definition of Steel Strip

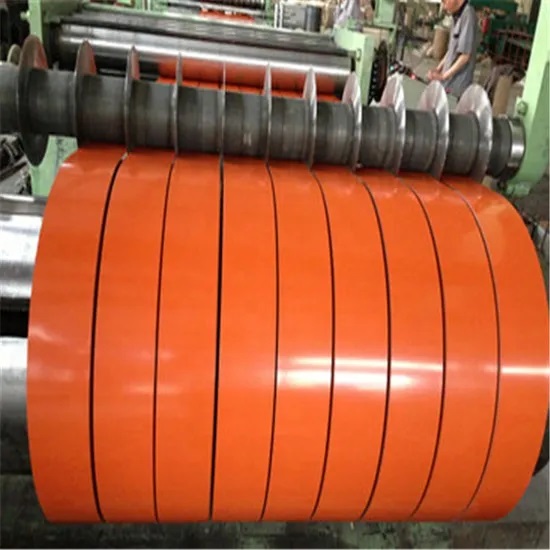

Steel Strip or cold rolled strip is a steel product that is produced from a hot rolled strip that has been pickled. The coil is then reduced by a single stand cold roll steel mill straight away or reversing mill or in a tandem mill consisting of several single stands in a series.

The strip is reduced to approximately final thickness by cold-rolling directly, or with the inclusion of an annealing operation at some intermediate thickness to facilitate further cold reduction or to obtain mechanical properties desired in the finished product.

Steel sheet vs Strip?

The greatest difference between strip and sheet is the width of the coiled product. Any coiled product 24” and wider is considered sheet, while anything under 24” is described as strip.

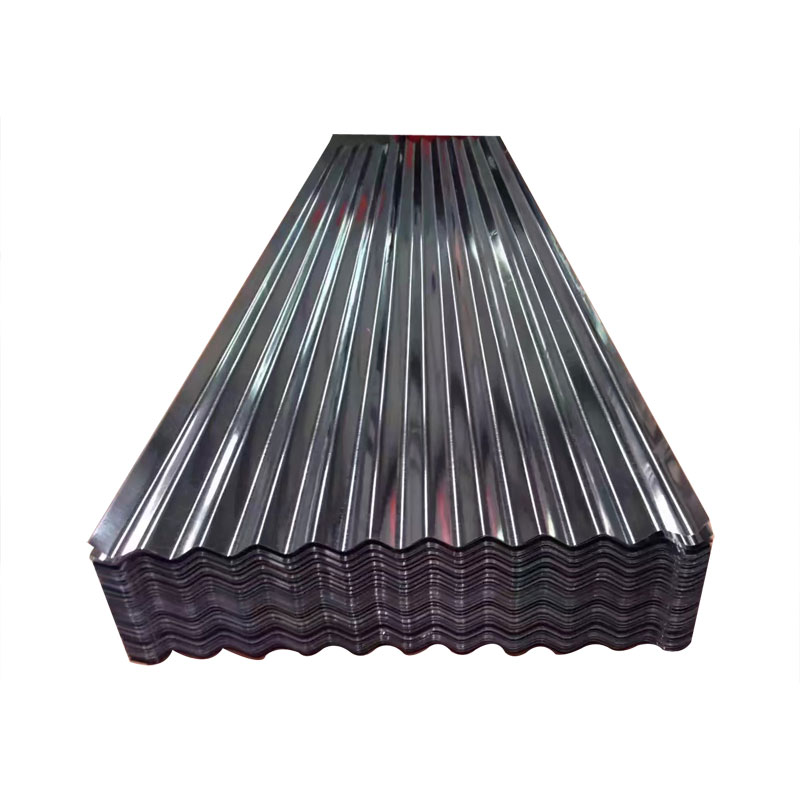

Galvanized Steel Strip: The Long-lasting and Cost-efficient Choice

Galvanized steel strip brings up to a steel strip that has been coated with a layer of zinc through a process known as galvanization. This process involves immersing the steel in molten zinc or using electroplating techniques to apply a thin, protective layer of zinc.

The primary purpose of galvanization is to prevent rusting and corrosion, making galvanized steel an excellent choice for environments prone to moisture and harsh weather conditions.

Key Benefits of Galvanized Steel Strip

- The zinc coating acts as a barrier to moisture, preventing the steel from corroding over time. This makes galvanized steel ideal for use in outdoor applications, such as fences, gates, and structural supports.

- Galvanized steel is relatively inexpensive compared to other forms of steel, making it a cost-effective solution for many industries.

- With proper maintenance, galvanized steel can last for decades, providing long-term value for your investment.

- Galvanized steel is used in a wide range of industries, including construction, automotive, and electrical industries.

Applications of Galvanized Steel Strip

- Construction

- Automotive parts

- Electrical applications

- Agricultural equipment

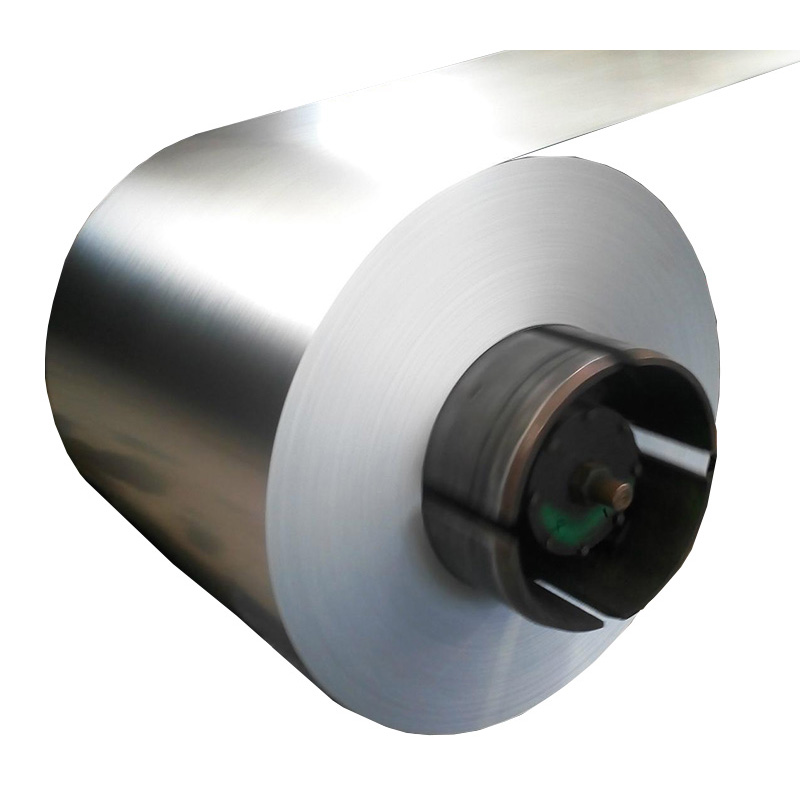

Galvalume Steel Strip/ Aluzinc Steel Strip: A Hybrid of Zinc and Aluminum

Galvalume steel strip is a type of coated steel that combines the protective properties of zinc and aluminum. The coating typically consists of approximately 55% aluminum and 43% zinc, with trace amounts of silicon.

This combination provides enhanced resistance to corrosion and weathering compared to traditional galvanized steel.

The galvalume coating is applied through a hot-dip process, similar to galvanization, but with the difference in the composition of the coating. The result is a steel strip with an improved resistance to high-temperature environments, as well as first-rate protective covering against corrosion caused by environmental causes.

Key Benefits of Galvalume Steel Strip

- The aluminum-zinc coating gives galvalume steel superior corrosion resistance, especially in harsh climates where high humidity or salt exposure is common.

- The aluminum content helps galvalume steel withstand high-temperature environments better than galvanized steel.

- Galvalume has a distinctive, attractive finish that is often used in architectural applications.

- Galvalume steel typically has a longer service life than galvanized steel in many applications, especially in roofing and cladding.

Applications of Galvalume Steel Strip

- Roofing and siding

- HVAC systems

- Agricultural and storage buildings

- Solar panel frames

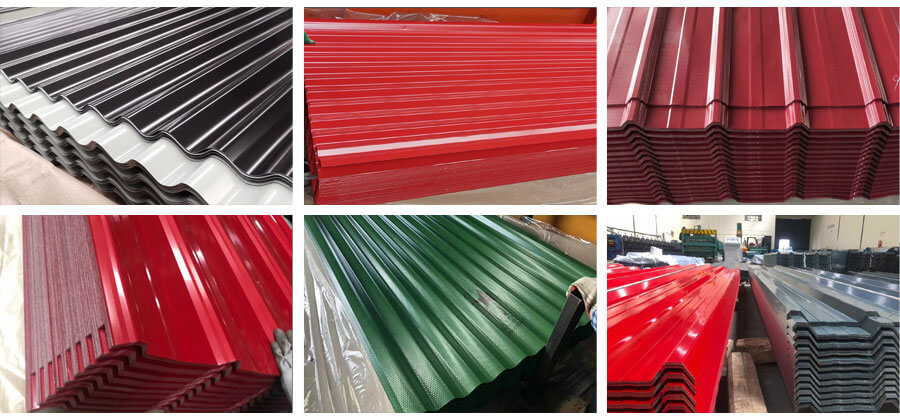

Prepainted Galvanized Roofing Sheet: Compounding Function with Aesthetic Charm

Prepainted galvanized roofing sheets are galvanized steel sheets that have been coated with an additional layer of paint before being rolled into the desired sheet form. This extra layer of paint not only enhances the appearance of the roofing sheet but also adds an additional layer of protection against corrosion and weathering.

The prepainting process involves applying a high-quality paint finish over the galvanized surface. This coating helps the roofing material maintain its aesthetic appeal over a long period, without the need for frequent maintenance.

Key Benefits of Prepainted Galvanized Roofing Sheet

- The availability of various colors and finishes makes prepainted galvanized roofing sheets an attractive option for architectural applications.

- The combination of the galvanized coating and the painted finish provides superior resistance to corrosion, weathering, and UV damage.

- The reflective nature of the paint helps to reduce heat absorption, thereby improving the energy efficiency of buildings by reducing cooling costs.

- The paint finish requires minimal upkeep, as it is resistant to fading, chipping, and peeling.

Applications of Prepainted Galvanized Roofing Sheet

- Residential and commercial roofing

- Agricultural buildings

- Warehouses and storage facilities

- Cladding and wall panels

Prepainted Galvalume Roofing Sheet: The Best of Both Worlds

Prepainted galvalume roofing sheets are concomitant to prepainted galvanized sheets, but they come with a galvalume-coated steel substrate rather than a galvanized one. This provides the roofing material with the corrosion resistance and high-temperature durability of galvalume, along with the aesthetic benefits of a prepainted finish. These roofing sheets are highly durable and are designed to withstand the harshest weather conditions.

Key Benefits of Prepainted Galvalume Roofing Sheet

- The combination of the galvalume coating and the paint finish offers excellent protection against corrosion, making these roofing sheets ideal for coastal areas and industrial environments.

- The durability of both the galvalume coating and the paint ensures that these sheets last longer than traditional galvanized options.

- The prepainted finish ensures that the color of the roofing sheet remains stable and vibrant for years, without fading due to exposure to the elements.

- The reflective paint finish helps in maintaining energy efficiency by reducing the amount of heat absorbed by the building.

Applications of Prepainted Galvalume Roofing Sheet

- Industrial and commercial roofing

- Residential buildings and homes

- Agricultural facilities

- Greenhouses and energy-efficient buildings

Concluding Remarks

Galvanized steel strip, galvalume steel strip, prepainted galvanized roofing sheet, and prepainted galvalume roofing sheet all offer distinct advantages for various applications.

Whether you’re constructing a building, designing a vehicle, or manufacturing agricultural equipment, these materials provide essential durability, corrosion resistance, and aesthetic appeal.

To sum up

Galvanized steel strip is ideal for general applications where corrosion resistance is crucial but the environment isn’t too harsh.

Galvalume/ Aluzinc steel strip offers enhanced performance in challenging conditions, particularly in terms of temperature and moisture resistance.

Prepainted galvanized and galvalume roofing sheets offer both beauty and protective cover, making them an fantabulous choice for roofing and cladding applications.

By understanding the differences and applications of these materials, you can make an informed decision and select the right product for your needs.

Witop Steel is a leading steel manufacturer which can produce the absolute collection of galvanized steel, galvalume steel, prepainted galvanized/galvalume steel strips and roofing steel sheet in China. With the self-reliant production capacity, our company has been attracting global customers these years.

What is steel strip hs code?

Galvanized Steel Strip HS Code 721230

Galvalume Steel Strip HS Code 721250

Prepainted Steel Strip HS Code 721240

How much is steel strip price?

Steel price can be determined based on material, thickness, coating thickness, packaging and other information

What is the thickness of metal strip?

Usully, the thickness range is 0.13-2.5mm.