Metal Furring Channel made of high-quality galvanized steel strips, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling. Metal furring channels are crucial components used in modern construction, particularly for supporting non-load bearing walls, ceilings, and certain types of finishing systems. This article will break down what a metal furring channel is, its key uses, and why it’s a favored choice for many contractors.

What is a Metal Furring Channel?

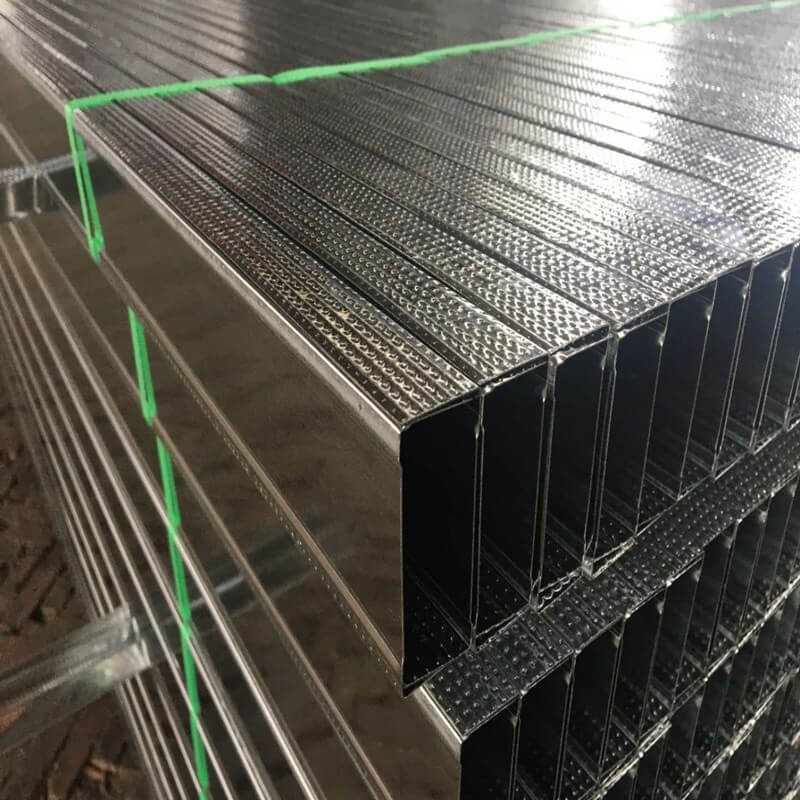

A metal furring channel is a lightweight, galvanized steel framing system. Typically shaped in a “C” or “Z” profile, these channels are used to create a framework that supports drywall, ceilings, or other finishing surfaces in both commercial and residential buildings. The system is highly adaptable and helps create an even, level surface, making it easier to install finishing materials like plasterboard.

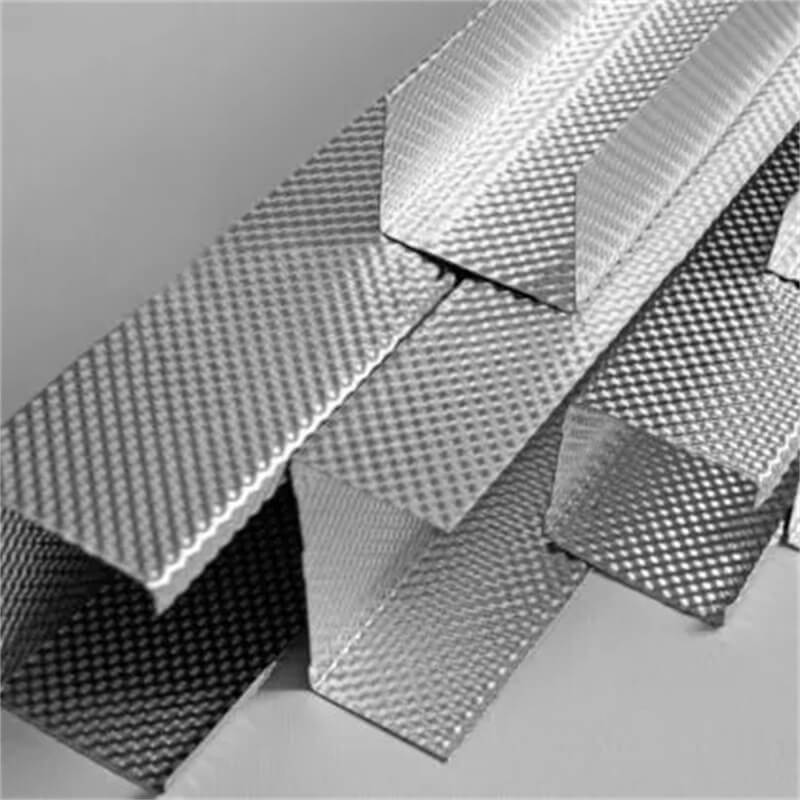

1. Metal Furring Channel

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling. Ceiling keel and wall channel has light-weight, high-intensity, good-antisepsis and other advantage-s. They mainly match to paperbacked plasterboard and other goods, also the other plates such as GRC.

The product has the following advantages:

1. Light, good strength,cauterization resistance and water resistance

2. Matching magnesium fire-proof board, gypsum board and many other wall and ceiling board

3. Moisure-proof, shock-resistant, high-effcient and environmentally-friendly

4. Easy and fast for installation, time-saving

5. Prompt delivery, high quality, competitive price and complete sets of styles

6. Galvanized Coating: Metal furring channels are often coated with zinc (galvanized) to prevent corrosion, increasing their lifespan.

7. Variety of Profiles: These channels come in various sizes and profiles depending on their intended use (e.g., “C” channel, “Z” channel, etc.).

Types of Metal Furring Channels

Metal furring channels are available in different shapes and sizes, each suited for specific uses.

1. C-Shaped Furring Channel

C-shaped channels are the most common type used in ceiling and wall construction. These channels are versatile and offer good support for drywall.

2. Z-Shaped Furring Channel

Z-shaped channels are often used in situations where additional strength is required or for cladding support in exterior walls. Their unique shape provides more stability.

2. Metal Furring Channel Applications:

Furring channel is widely used in construction industry, which is used to connect the suspended ceiling or wall and various veneers, such as gypsum board, mineral fiber ceiling board etc. Lightweight suspended ceilings or partition walls composed of furring channels are widely used in building decoration projects due to their high-quality thermal, acoustic, mechanical, technological performance and variable decorative styles.

Metal furring channels are primarily used in interior construction. Let’s explore their different applications.

1. Ceiling Support Systems

Metal furring channels are widely used in suspended ceiling systems. The channels are arranged in a grid, providing a strong framework where ceiling tiles or plasterboard can be installed. The channels make it easier to run electrical wiring, air conditioning ducts, or lighting fixtures above the ceiling, while still offering a clean and finished look from below.

2. Wall Framing for Drywall

These channels are excellent for creating smooth, flat surfaces for drywall installation. They offer better structural support than wooden studs and are ideal for places with high moisture levels, as they don’t rot or warp.

3. Fireproofing and Soundproofing

In projects requiring fire-rated or soundproof walls, metal furring channels offer a strong base to support additional layers of materials that contribute to fire resistance and noise reduction. This makes them a popular choice for office buildings, cinemas, and hotels.

4. Cladding Support

In exterior applications, metal furring channels can support lightweight cladding systems. Their corrosion-resistant properties ensure they can withstand exposure to the elements without deteriorating quickly.

Why Choose Metal Furring Over Wood?

Furring channels made from metal offer distinct advantages over wood alternatives.

- Moisture and Corrosion Resistance: Metal does not warp, rot, or become affected by mold when exposed to moisture, making it a superior choice in areas with high humidity or in places where moisture buildup is common.

- Strength and Durability: Metal furring channels provide greater strength, ensuring that the framework remains stable for many years without bending or weakening.

- Fire Safety: Metal is non-combustible, meaning it adds a layer of fire safety to any structure, an important consideration in both residential and commercial buildings.

- Precision and Versatility: Metal furring channels can be manufactured to exact specifications, ensuring precise measurements and fitting. This is especially valuable in projects requiring high levels of accuracy.

Install

In concrete wall applications:

Install the blank channel vertically to the wall surface using concrete nails or power fasteners. Then screw the drywall to the sink channel.

In suspended ceiling applications:

Furring channels can be attached directly to t1-1/2″ cold rolled channels using metal Furring channel clips or tie wires. Screws or power fasteners can be used to attach Furring channels directly to building structures.

Heavier gauge scales allow for greater span and load capacity. 18 or 16 gauge limescale is typically used for purlins in exterior applications.

Quality Control & Inspection

Our workshop staff will inspect the finished product from the following aspect:

① Check if the size is within the tolerance.

② Check the mechanical properties, to ensure all meet the standards.

③ Check the zinc coating, to ensure the best quality of products.

Packing & Shipment

Generally, the furring channels are packed with bundles, but we can also make the package according to client’s requirement.

Conclusion

Metal furring channels are an essential component in modern construction, providing reliable support for walls, ceilings, and cladding systems. Their durability, resistance to moisture, and fireproof properties make them the go-to choice over wood framing. Whether you’re working on an interior drywall project or an exterior cladding system, metal furring channels offer versatility and strength that ensure the longevity of any construction project.

Always ensure you choose the right profile for your specific project needs, and as with any material, proper installation is key to achieving the best results.