Basic Introduction: Knowing Steel coil

Steel coils are important in the sense that they serve as a vital part of the base material in the arena of construction, manufacturing, and infrastructure development.

Unlike steel sheets which remain flat, steel coils are continuous sheets of steel that are wound into a roll-like cylindrical shape. The manufacturing process for steel coils involves two primary methods: hot rolling and cold rolling.

Hot rolled coils are produced by heating the steel above its re-crystallization temperature, resulting in a rougher surface and a larger range of dimensional sizes. On the other hand, cold rolled coils are processed at room temperature, providing a smoother surface finish and more precise dimensional tolerances.

Whether you’re new to an industry or simply seeking to enhance your knowledge, this blog post will answer as a practical guide.

Among different versions of Steel coil, ‘galvanized steel coil’, ‘galvalume steel coil’, ‘aluzinc steel coil’, and ‘prepainted versions’ will be discussed in detail. Each of these products offers unparalleled advantages, making them necessary in different industries.

Steel coil measurements

The size of a steel coil is typically expressed through three main measurements; width, thickness, and length.

Width – refers to the measurement from one edge to the other across its flattened surface. This is a vital measurement, as it determines the maximum distance between the edges of the sheet (or if the coil needs to be slit).

Thickness – indicates the depth of each “layer” of the steel coil, or the thickness of the sheet once unrolled. Can be measured in gauges or inches.

Length – the full length of the steel coil when completely unrolled. This is important to determine how many coils a project may need, or as an indicator of a coil’s weight.

Other measurements you might see include:

Outside Diameter (OD) – refers to the measurement across the outer edges of the coil. It plays a crucial role in determining how the coil fits within specific machinery or storage facilities and affects transportation logistics due to its size and weight.

Inside Diameter (ID) – indicates the measurement across the inner core of the coil. This measurement is important for compatibility with machinery and equipment that require a specific inner diameter for efficient operation.

Additionally, it influences the stability and handling of the coil during transportation and storage.

It’s important to remember that each steel coil is unique, and its measurements and weight can vary based on its intended application and the processing techniques used. This is why knowing these basics is critical when purchasing steel coils.

A Comparative study of Top Three versions of Steel Coils: Let’s get a better understanding

| Varieties | Overview | Advantages | Common Applications |

| Galvanized Steel Coil (GI) | It is a variety of steel product that has been coated with a layer of zinc to forbid rusting. This process, known as galvanization, involves immersing the steel in molten zinc to create a corrosion-resistant layer. The zinc coating acts as a obstruction, protecting the steel core from the influence of moisture and oxygen, which are the important reasons of rust.

|

Corrosion resistance, Cost-Effective, Ease of Maintenance, Versatility | Galvanized steel coil is widely used in industries where steel is exposed to the elements.

ü Roofing and wall panels ü HVAC ducts ü Automotive parts |

| Galvalume steel coil (GL) | It is a type of steel that is coated with a layer of coating composition—55% aluminum, 43.4% zinc, and 1.6% silicon to enhance its resistance to oxidation and corrosion.

This coating combines the properties of both galvanized steel and aluminum, offering superior protection and heat resistance. Aluzinc Steel Coils combination provides enhanced corrosion resistance, especially in environments with high moisture or exposure to extreme temperatures.

|

Enhanced Lastingness, Heat Resistance, Longer Lifespan

Corrosion Resistance, Reflectivity, Formability. |

ü Roofing and siding

ü Appliances and HVAC systems ü Industrial applications ü Storage tanks ü Heating systems |

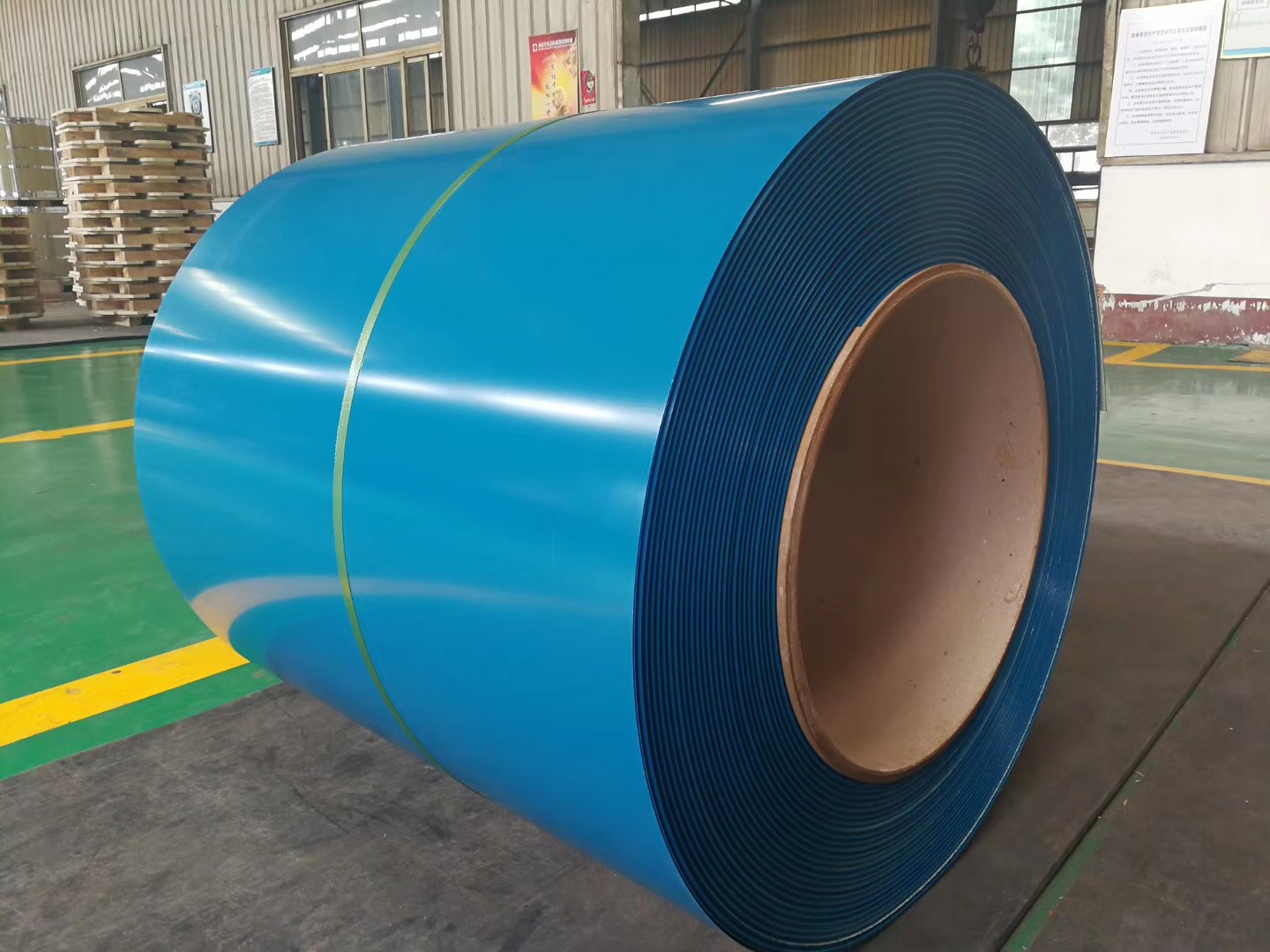

Prepainted Galvanized and Galvalume Steel Coil: Increasing Aesthetic appealing

What are Prepainted Steel Coils?

‘Prepainted galvanized steel coil’ and ‘prepainted galvalume steel coil’ are versions of galvanized and galvalume steel that have been coated with paint for additional protection and aesthetics. The steel coils are first treated with an anti-corrosion layer and then coated with a high-quality paint that provides both aesthetic appeal and an additional protective layer.

Advantages of Prepainted Steel Coils

- Aesthetic Appeal: Available in a variety of colors and finishes, they are widely used in architectural projects.

- Increased Durability: The paint layer adds another barrier of protection against the elements, enhancing the steel’s lifespan.

- Customization: Prepainted steel can be customized to meet the specific aesthetic and functional needs of a project.

Common Applications

- Architectural panels

- Automotive industry

- Appliances

When it comes to cost optimization and meeting specific usage requirements, the selection of pre-painted steel coils, including PPGI (Pre-painted Galvanized Steel Coil) and PPGL (Pre-painted Galvalume Steel Coil), becomes crucial.

Responsible steel buyers understand the importance of making informed material choices, especially when it comes to these products offering a diverse range of options, each tailored to suit various applications and industries with their unique characteristics.

To ensure optimal results, including cost-effectiveness and superior product performance, buyers should consider some key factors such as mechanical properties, metal coating types and coil weight. Performance of top and back coating is another crucial factor to be considered.

What is Electrolytic Tinplate?

‘Electrolytic tinplate’ is a type of steel, coated with a thin layer of tin through an electrolytic process. This tin layer offers corrosion resistance, protects the steel from the elements, and ensures food safety, which is why it is commonly used in packaging applications.

Advantages of Electrolytic Tinplate

- Corrosion Resistance

- Non-toxic

- Recyclable

Common Applications

- Cans and containers

- Electrical components

- Decorative applications

What are Colour Stone Coated Roofing Tiles?

‘Colour stone-coated roofing tiles’ are made from a steel base (typically galvanized or galvalume steel) coated with a layer of coloured stone granules. These tiles combine the strength of steel with the aesthetic appeal of traditional roofing materials such as clay or slate, offering a durable and visually attractive solution for roofing.

Advantages of Colour Stone Coated Roofing Tiles

- Durability

- Aesthetic Variety

- Lightweight

- Weather Resistance

Common Applications

Colour stone-coated roofing tiles are normally used in residential and commercial buildings.

They are particularly popular in regions prone to extreme weather, such as hurricanes, due to their durability and resistance to environmental damage.

Expert’s perspectives

Experts view steel coils as foundational to many sectors but note that producers must sail a complex landscape of market forces, technological advances, and regulatory challenges to remain competitive.

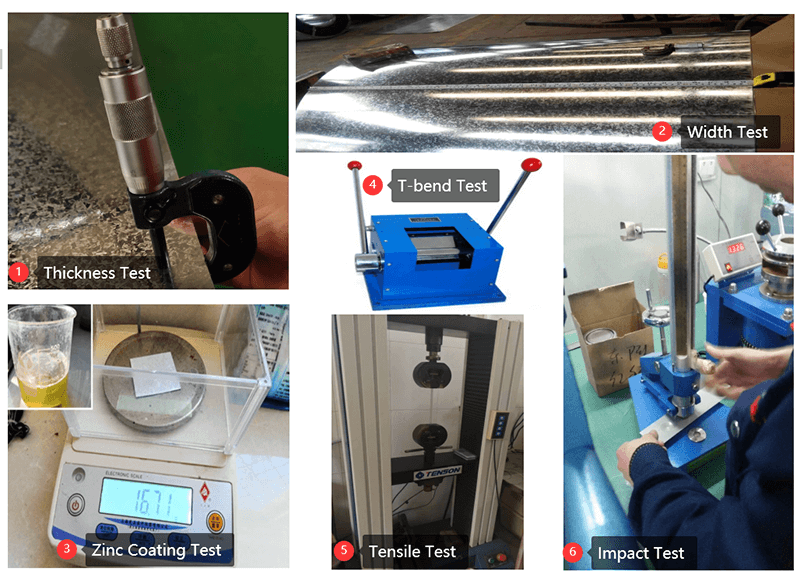

As a leading steel coils supplier in China, Qingdao Witop Steel has always provided our customers with the highest quality products.

Witop Steel offers a complete range of customizable steel coil options in various sizes, grades, finishes, and forms. Our team of experienced engineers guarantee that each coil is well-tried and outperforms in the ever competitive market world wide.

Concluding Remarks

From ‘galvanized steel coil’ to ‘color stone-coated roofing tiles’, the innovations in steel products have revolutionized the construction, automotive, and manufacturing industries.

Each product offers unique advantages tailored to specific needs. With their enhanced durability, corrosion resistance, and aesthetic appeal, these materials continue to be integral to modern infrastructure and design. As you explore options for your next project, understanding the differences between these steel products will help you choose the best solution for your application.