Steel Coil Definition and Classification

Steel coils are steel sheets that are wound after being rolled. These coils are often used in industries such as construction, automotive manufacturing, appliance production, and more, thanks to their versatility and ease of transportation and storage.

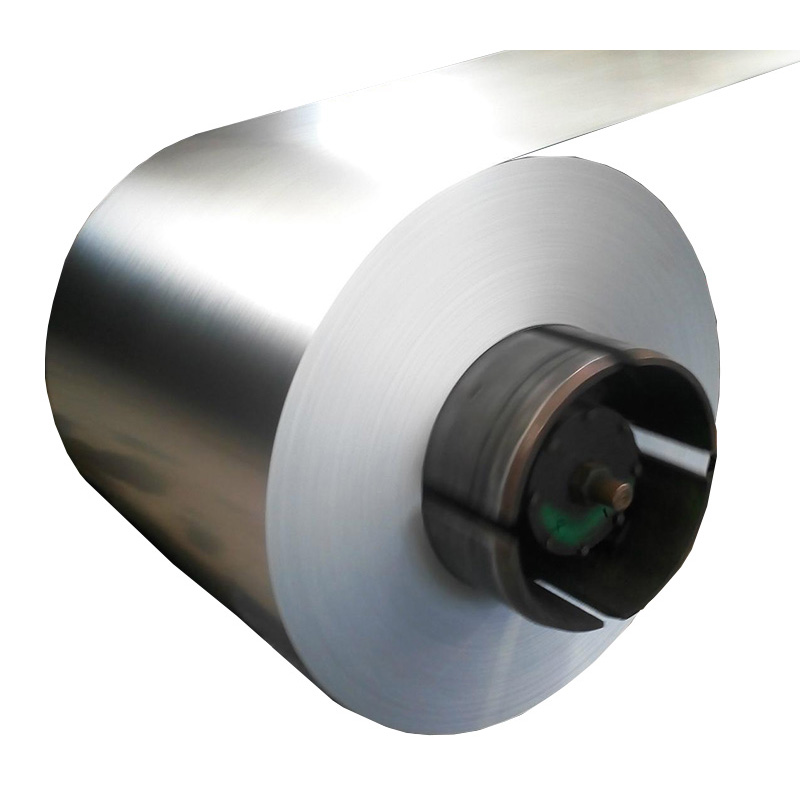

Definition of Steel Coil

Steel coil is a finished product of the steel manufacturing process that comes in the form of a coiled sheet. Depending on the application, the steel can either be hot-rolled or cold-rolled, each offering different mechanical properties and surface finishes.

Classification of Steel Coils

Steel coils can be classified based on several factors, such as:

1. Production Process

- Hot-Rolled Steel Coil: Steel that has been roll-pressed at high temperatures, typically above the material’s recrystallization temperature. Hot-rolled coils have a rougher surface texture and are usually thicker than cold-rolled steel. These are used for applications where precise shapes and tolerances are less critical.

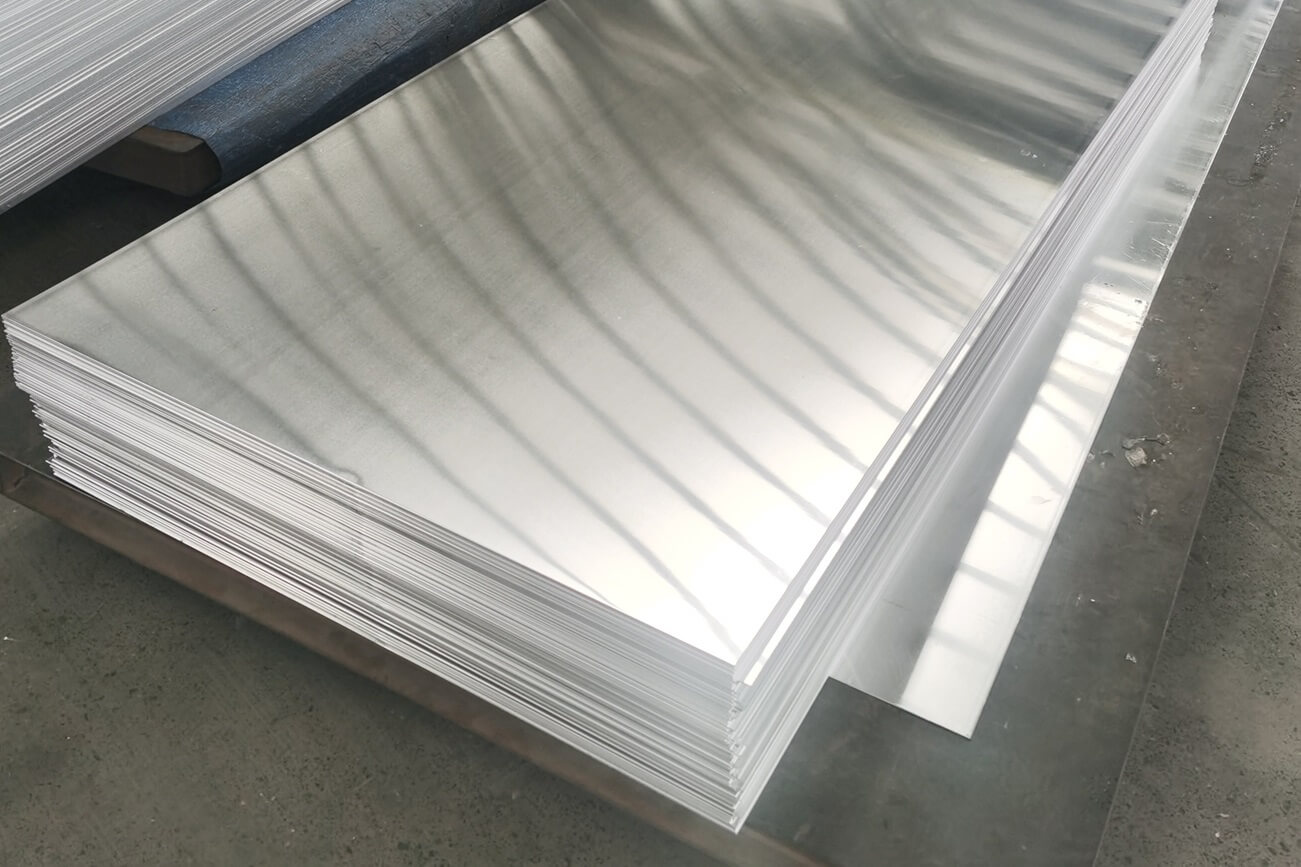

- Cold-Rolled Steel Coil: Produced by rolling steel at room temperature, cold-rolled coils have a smoother surface and better dimensional accuracy. These are often used in industries requiring thin sheets and precision, such as automotive parts, appliances, and construction materials.

- Key Differences Between Hot-Rolled and Cold-Rolled Steel Coils

- Hot-Rolled Steel Coils are created using high-temperature processes, resulting in a less precise and rougher surface. These coils are ideal for construction materials and other applications where surface finish isn’t a priority.

- Cold-Rolled Steel Coils are processed at room temperature, offering greater precision and a smoother surface, making them suitable for automotive body parts and home appliances.

2. Coating and Surface Treatment

-

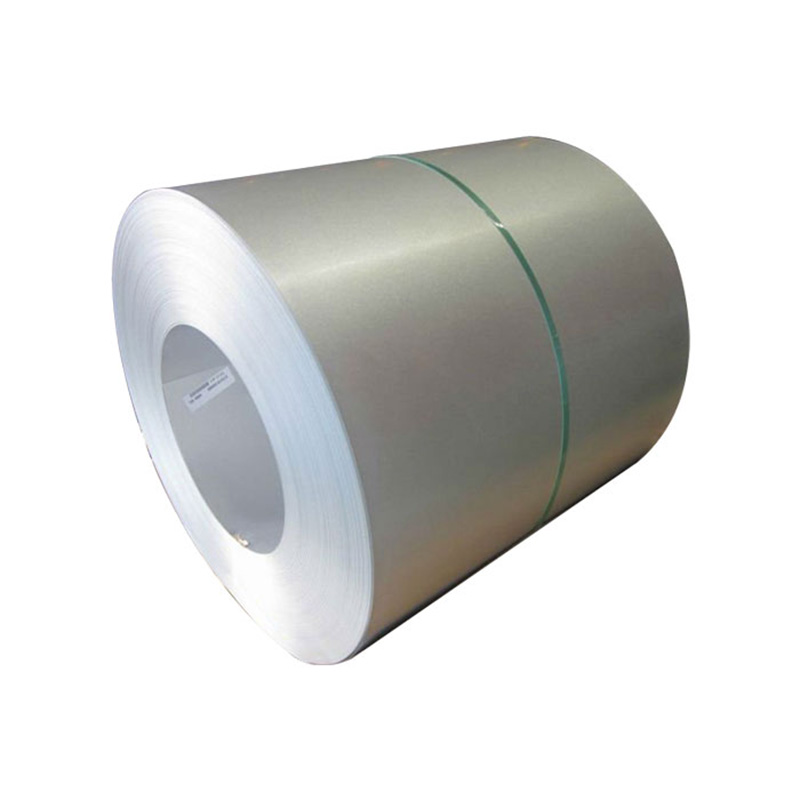

- Galvanized Steel Coil: Coated with a layer of zinc for enhanced corrosion resistance. This type is ideal for outdoor applications like roofing and cladding.

- Galvalume Steel Coil: Coated with a mix of zinc, aluminum, and silicon, providing better corrosion resistance than regular galvanized steel. These coils are often used in coastal or industrial environments.

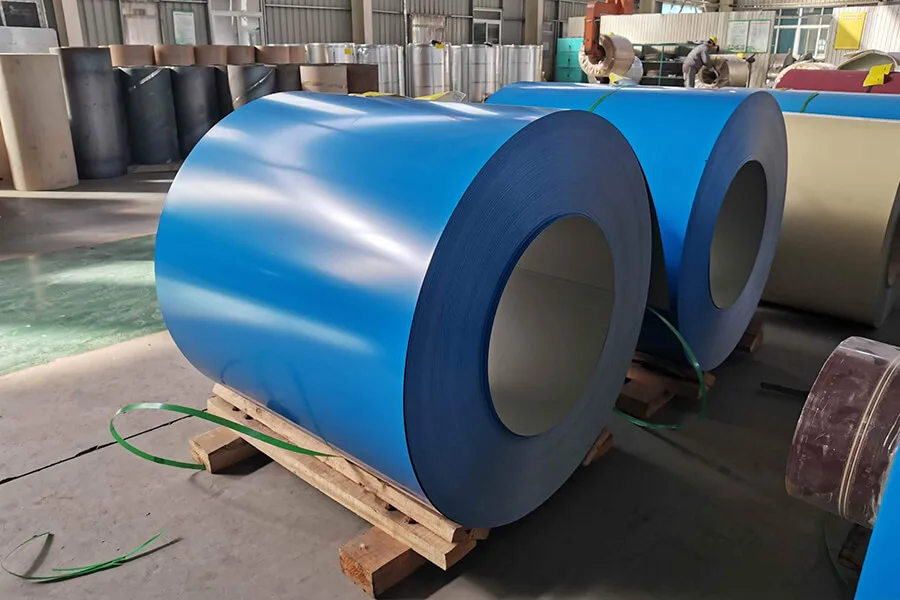

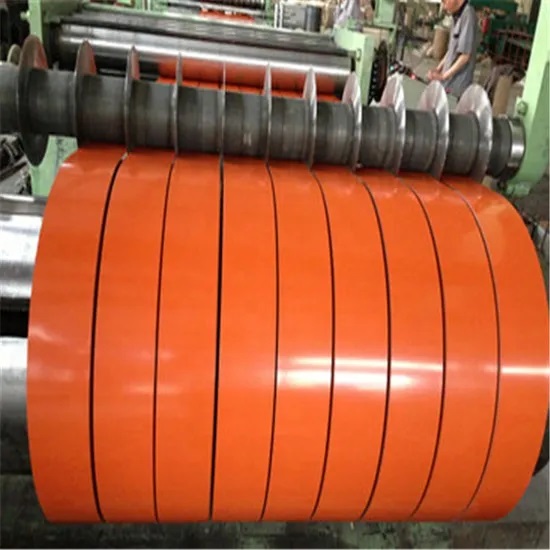

- Pre-painted Steel Coil (PPGI/PPGL): Painted or pre-coated steel coils that come in a variety of colors and finishes. They are commonly used in visible architectural applications.

- Zinc Aluminum Magnesium Coated Steel Coil: A newer coating technology that combines zinc, aluminum, and magnesium to offer improved durability and corrosion resistance.

3. Material Types

- Carbon Steel Coil: Made of carbon steel, known for its strength and hardness. It is one of the most commonly used types of steel in industrial applications.

- Stainless Steel Coil: Composed mainly of iron, chromium, and nickel, stainless steel is resistant to corrosion and heat. It is used in food production, medical equipment, and other environments where hygiene and cleanliness are critical.

- Alloy Steel Coil: Contains additional elements like manganese, silicon, or aluminum to enhance certain properties, such as strength or wear resistance.

4. Thickness or Gauge

- Thin Coils: Typically used in applications requiring light weight and flexibility, such as automotive panels and appliances.

- Thick Coils: Used for construction, shipbuilding, and heavy machinery manufacturing.

5. Application of Stel Coil

- Structural Steel Coil: Designed for construction applications like beams, rails, and columns.

- Electrical Steel Coil: Optimized for use in electrical applications, such as transformers and motors, thanks to its magnetic properties.

- Construction: Structural beams, roofing sheets, and frameworks are made from steel coils.

- Automotive: Steel coils are essential for producing vehicle bodies, engine components, and other automotive parts.

- Appliances: Cold-rolled and galvanized steel coils are widely used in home appliances due to their strength and resistance to rust.

- Manufacturing: Steel coils are used to make various products, from pipes and tubes to storage tanks and packaging materials.

Conclusion

Steel coils are an essential part of modern manufacturing, offering a wide range of types, coatings, and uses. Whether hot-rolled or cold-rolled, coated or uncoated, the right choice of steel coil depends heavily on the application and the environment in which it will be used. For more in-depth information, you can consult industry resources or manufacturers’ specifications.