Introduction on Roofing Sheets

Selecting the right roofing material is a vital decision for homeowners, contractors, and architects alike. In addition to protecting a building from the elements, roofing materials also add significantly to energy efficiency, curb appeal, and longevity. Today, roofing materials are available in a wide variety of metals and coatings, making it easier to tailor roofing to specific needs.

Major types of roofing sheets with

In this guide, we’ll discuss the benefits and applications of major types of roofing sheets such as galvanized roofing sheets, aluzinc roofing sheets, and colour coated steel roofing sheets, catering you with the information you need to choose the ideal material for your next roofing project.

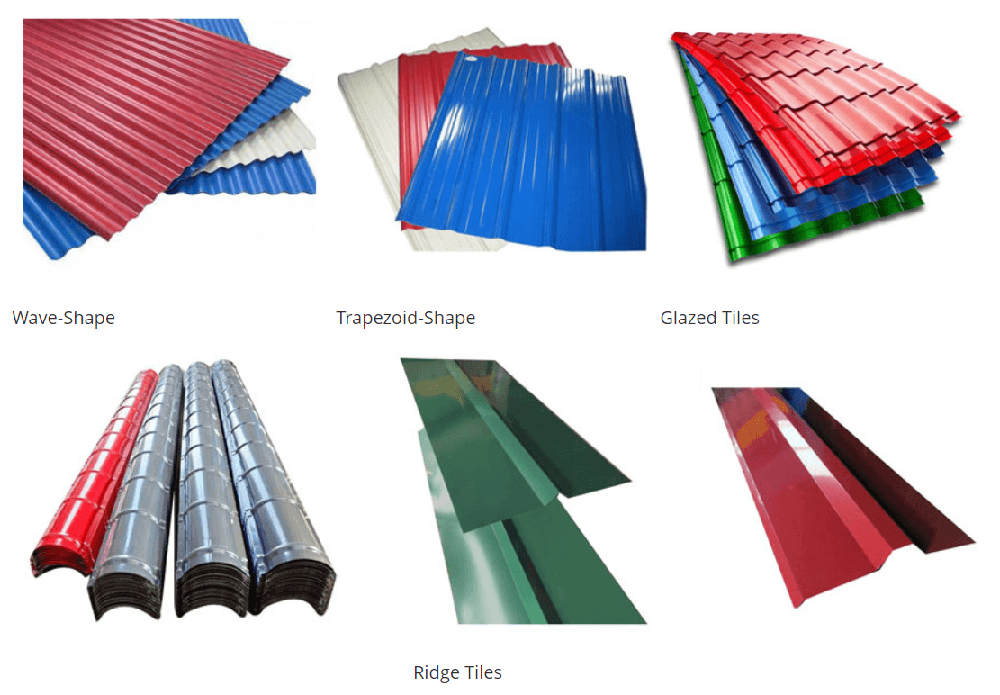

Qingdao witop steel group is a premier manufacturer ans supplier of roofing sheets with ten roll corrugated forming machines, which can produce more than 30 roofing shapes and models.

Especially, roofing sheet with the thickness from 0.10mm to 0.25mm have very good quality and cheaper price than others. We can produce 1000mm to 6000mm long roofing sheet.

Qingdao witop steel group are one of the biggest colour coated roofing sheet manufacturers in China and supply the roofing sheets in foreign market too. We have five cutting machines and ten roll corrugated forming machines, which can produce more than 30 roofing shapes and models, including wave-shaped, T-shaped and glazed tiles.

Galvanized Roofing Sheet: A Durable and Cost-Effective Choice

A galvanized roofing sheet is made from steel that has been coated with zinc to protect it from corrosion. The zinc layer acts as a barrier to moisture and environmental elements, making it resistant to rust and degradation. Galvanization is done through a hot-dip process, where the steel sheet is dipped in molten zinc, creating a uniform protective coating. This process is well-established and has been widely used in roofing for decades.

Significant Benefits of Galvanized Roofing Sheets

- Corrosion Resistance

- Durability

- Cost-Effective

- Ease of Installation

Varieties of Galvanized Roofing Sheets

- Plain Galvanized Sheets: These are smooth sheets with no extra coating or pattern, often used for industrial and agricultural purposes.

- Corrugated Galvanized Sheets: These sheets have a wavy pattern that increases strength and water resistance, making them popular in residential and commercial roofing.

- 3. Galvanized Trapezoidal Sheets: These have a trapezoidal shape, providing additional rigidity and a modern look for roofing and siding.

Applications of Galvanized Roofing Sheets

- Residential Roofing: Galvanized sheets are widely used in residential roofing, especially in rural areas and regions with moderate climates.

- Commercial and Industrial Buildings: Due to their durability and cost-effectiveness, galvanized sheets are commonly used in warehouses, factories, and workshops.

- Agricultural Buildings: Galvanized sheets are also popular in barns, sheds, and other agricultural buildings where durability and resistance to corrosion are essential.

Considerations for Galvanized Roofing Sheets

While galvanized roofing sheets offer great value and protection, they are not ideal for highly corrosive environments, such as coastal areas where salt can accelerate corrosion.

Additionally, galvanized roofing tends to weather over time, resulting in a rustic or aged appearance that may not be suitable for all architectural styles.

Aluzinc Roofing Sheet: Enhanced Durability and Longevity

Aluzinc roofing sheets, also known as galvalume sheets, are steel sheets coated with a combination of aluminum (about 55%), zinc (about 43%), and a small amount of silicon.

This unique coating provides enhanced corrosion resistance and heat reflectivity, making aluzinc roofing sheets ideal for extreme climates and demanding applications. The aluminum in the coating offers a strong barrier to oxidation, while the zinc provides a robust layer of protection against corrosion.

Significant Benefits of Aluzinc Roofing Sheets

- Superior Corrosion Resistance

- High-Temperature Resistance

- Reflectivity and Energy Efficiency

- Extended Lifespan

Varieties of Aluzinc Roofing Sheets

- Corrugated Aluzinc Sheets: These have a wave pattern that improves structural strength and water runoff, making them suitable for roofing.

- Trapezoidal Aluzinc Sheets: The trapezoidal shape adds additional strength and rigidity, making them ideal for both roofing and siding in industrial buildings.

- Standing Seam Aluzinc Sheets: These sheets have a sleek design and interlocking seams, making them suitable for modern architectural applications.

Applications of Aluzinc Roofing Sheets

- Coastal and Industrial Areas: The corrosion-resistant properties of aluzinc make it ideal for buildings near the ocean or in industrial zones with high humidity.

- Solar Panel Mounting Systems: Aluzinc’s reflective properties make it an excellent choice for solar applications, reducing heat absorption and improving panel efficiency.

- Commercial and Agricultural Buildings: Its durability and resistance to corrosion make aluzinc sheets ideal for use in factories, warehouses, and farm buildings.

Considerations for Aluzinc Roofing Sheets

Aluzinc roofing sheets can be more expensive than traditional galvanized sheets. However, their longer lifespan and low maintenance requirements often make up for the higher initial cost.

In addition, aluzinc’s shiny finish may not blend well with some architectural styles, although it can be painted or coated to achieve a more muted look.

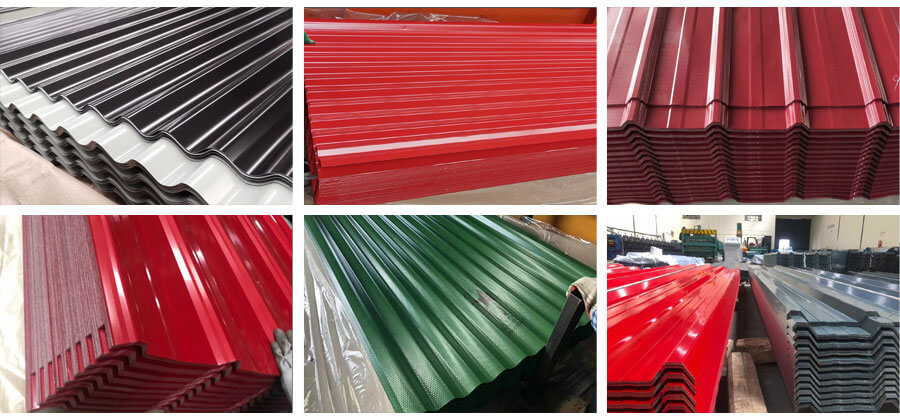

Colour Coated Steel Roofing Sheet: Combination of Durability and Aesthetic Appeal

Colour coated steel roofing sheets, also known as pre-painted steel sheets, are galvanized or aluzinc sheets that have been coated with a layer of paint.

These sheets offer the benefits of traditional metal roofing along with aesthetic versatility, allowing homeowners and designers to select from a wide range of colours and finishes.

The painted coating not only intensify the visual aspect of the roof but also adds an extra layer of protection against corrosion and environmental wear.

Significant Benefits of Color Coated Steel Roofing Sheets

- Enhanced Aesthetic Appeal

- Additional Corrosion Protection

- Fade and Scratch Resistance

- Low Maintenance

Varieties of Color Coated Steel Roofing Sheets

- Polyester Coated Sheets: These are the most commonly used color coated sheets and are available in a wide range of colors. They are affordable and provide good corrosion resistance.

- PVDF Coated Sheets: Polyvinylidene fluoride (PVDF) coatings are known for their excellent color retention and resistance to fading. They are ideal for projects where long-lasting color is important.

- Silicone-modified polyester Coated Sheets: These sheets offer high scratch resistance and durability, making them suitable for heavy-duty applications.

Applications of Color Coated Steel Roofing Sheets

- Residential Roofing: Colour coated sheets are popular in residential roofing as they offer aesthetic versatility, allowing homeowners to choose a color that complements the overall design of their home.

- Commercial Buildings: The vibrant colors of color coated steel sheets make them suitable for retail spaces, schools, and offices where appearance is a priority.

- Architectural Projects: Colour coated sheets are widely used in modern architecture, as they allow designers to create visually appealing roofs and facades that stand out.

Comparing Galvanized, Aluzinc, and Colour Coated Steel Roofing Sheets

Considerations for Colour Coated Steel Roofing Sheets

While color coated sheets offer aesthetic appeal and additional protection, they tend to be more expensive than traditional galvanized or aluzinc sheets.

Furthermore, the quality of the paint can vary, so it’s essential to choose high-quality coatings from reputable manufacturers to ensure long-lasting performance.

Comparing Galvanized, Aluzinc, and Colour Coated Steel Roofing Sheets

| Feature | Galvanized | Aluzinc | Colour Coated |

| Rust Resistance | Moderate | High | High |

| Durability | Moderate | High | Very High |

| Appearance | Plain metallic | Bluish-silver metallic | Custom colours |

| Cost | Affordable | Moderate | Higher |

| Best For | Mild climates | Harsh climates | Aesthetic & harsh climates |

| Maintenance | Regular maintenance | Low maintenance | Minimal maintenance |

Conclusion: Making an informed decision

Each type of roofing material has its own strengths and is best suited for specific environments and applications. By carefully considering your project’s requirements, you can choose the roofing sheet that best meets your needs, ensuring a durable, functional, and visually appealing roof.

Choosing the Right Option

For Cost Efficiency: Galvanized sheets are best for basic applications with less exposure to harsh weather.

For Corrosion Resistance: Aluzinc is ideal, particularly in coastal or industrial environments.

For Aesthetics and Durability: Colour coated sheets are preferred for long-term durability and visual appeal.

Qingdao Witop Steel Group is a favourite destination for major types of roofing sheets according to customer’s demand.

The steel enterprise has seen momentous beforehand in manufacturing techniques, providing a wide array of products for various applications. Among these, galvanized steel strip, galvalume steel strip, aluzinc steel strip, prepainted galvanized roofing sheet, and prepainted galvalume roofing sheet are some of the most commonly used materials in construction, automotive, and manufacturing industries.

In this blog post, we will look into the characteristics, differences, and applications of these materials to help you understand their benefits and guide you in selecting the right one for your needs.

What is steel strip hs code?

Galvanized Steel Strip HS Code 721230

Galvalume Steel Strip HS Code 721250

Prepainted Steel Strip HS Code 721240

How much is steel strip price?

Steel price can be determined based on material, thickness, coating thickness, packaging and other information

What is the thickness of metal strip?

Usully, the thickness range is 0.13-2.5mm.