Introduction

Roofing nails are constitutive components of any roofing project, ascertaining a secure and long-lasting installation. These nails are designed to prevent tearing and provide a secure hold. They are critical for maintaining the integrity of the waterproof barrier on roofing projects.

Choosing the right type of nail can make a significant difference in the durability of the roof. Whether you are working on a metal roof, a tile roof, or a shingle roof, understanding the different types of roofing nails available in the market is crucial. In this guide, we will discuss the various types of roofing nails, their applications, and factors affecting their price.

Basics of Roofing Nails: Key highlights

Roofing nails, otherwise known as ‘roofing tacks,’ typically have a larger, flat head and a short shank. This design ensures maximum holding power and prevents the nail from pushing too far into the roofing material. As inconspicuous as they may seem, these tiny roof warriors come in various types and sizes, each designed to perform optimally under particular roofing conditions.

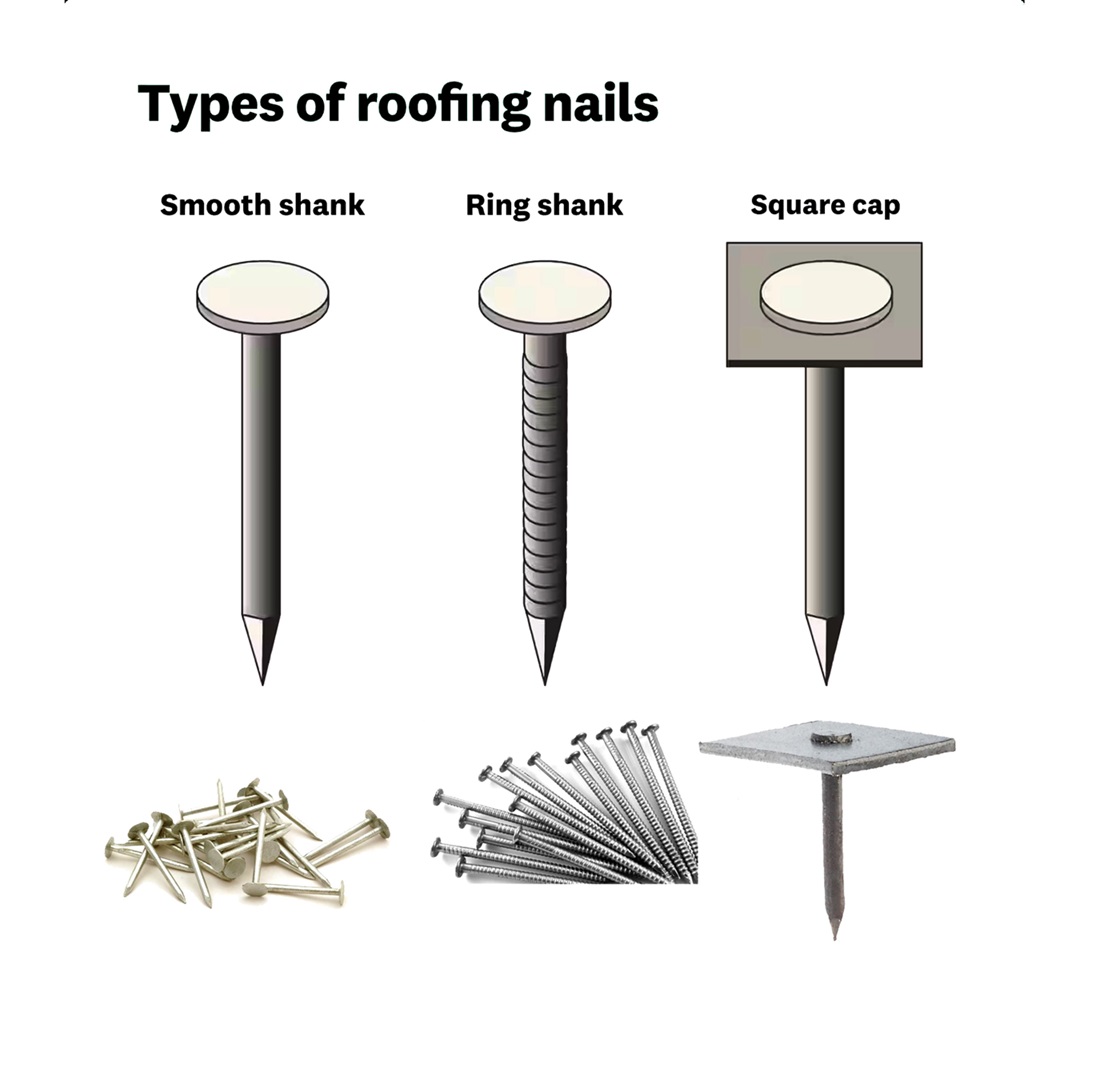

The shank of the nail is the part of the nail that punctures through the material you are nailing. On the basis of the texture of the shank, Roofing nails are of three types:

- Smooth Shank: Simply put, smooth shank nails have a smooth shank. They are the most basic type of roofing nail and cheaper than the other two options.

- Ring Shank: As its many names suggest, this type of nail has rings along the shank. They aren’t connected, as they are with screws. Still, these rings give the nail extra staying power, or grip, in the shingles and sheathing.

- Square Cap: Square cap nails are typically used for fastening felt underlayment and not asphalt shingles. They have a square-shaped head, instead of the more typical circular head you see on other nails. Square cap nails may have a smooth or coiled shank.

Depicting three types of Roofing nails on the basis of shank texture

Understanding Roofing Nails in more detail

1. IBR Roof Nails

IBR roof nails are specifically designed for IBR (Inverted Box Rib) roofing sheets, commonly used in industrial and residential buildings. These nails often feature a larger head to provide better holding power and are usually made of galvanized steel for corrosion resistance.

2. Steel Roofing Nails

Steel roofing nails are popular due to their strength and resistance to weather conditions. They are available in different coatings, such as hot-dipped galvanized or stainless steel, to prevent rust and extend longevity. These nails are ideal for securing metal roofing sheets.

3. Roof Tile Nails

Roof tile nails are specially crafted to secure tiles to wooden battens. These nails have a longer shank and are often made from copper, aluminum, or stainless steel to prevent corrosion. Some variants come with a ringed or twisted shank for additional grip.

4. 4-Inch Roofing Nails

For projects that require extra length, 4-inch roofing nails are a go-to option. They provide deeper penetration, ensuring strong attachment, especially for thicker roofing materials such as wood shakes or multiple layers of shingles.

5. Umbrella Head Roofing Nails

Umbrella head roofing nail are designed with a wide, dome-shaped head to distribute pressure evenly, reducing the risk of material damage. These nails are ideal for securing roofing felt, asphalt shingles, and some metal sheets.

6. Hot Dipped Galvanized Roofing Nails

Hot dipped galvanized roofing nail undergo a special coating process where they are dipped in molten zinc. This process creates a highly durable, corrosion-resistant nail, making them ideal for areas with high humidity, heavy rain, or coastal regions.

Factors Affecting Roof Nails Price

The price of roofing nails varies based on multiple factors. Understanding these aspects can help you make an informed purchase decision.

1. Material and Coating

Steel roofing nails, especially those with a galvanized or stainless-steel coating, are more expensive than basic iron nails due to their durability and rust resistance.

2. Nail Length and Size

Longer and thicker nails, such as 4-inch roofing nails, tend to cost more than shorter, thinner nails. Larger nails require more material in manufacturing, increasing their price.

3. Quantity and Packaging

Buying nails in bulk often reduces the cost per unit. Roofing nails are usually sold in boxes or cartons, with prices depending on the quantity and weight.

4. Brand and Manufacturer

Premium brands that specialize in high-quality fasteners may charge more due to their reputation for reliability and performance.

5. Market Demand and Supply

Seasonal fluctuations and raw material costs impact the overall price of roofing nails. Prices tend to rise during peak construction seasons.

Roofing Nailer: A Must-Have Tool

A roofing nailer is a specialized power tool designed to drive roofing nails efficiently and quickly. It helps save time and effort in large-scale roofing projects. Here are some benefits:

- Speed and Efficiency: A roofing nailer drives nails faster than manual hammering, significantly reducing installation time.

- Consistency: It ensures uniform depth and positioning, leading to a professional finish.

- Reduced Fatigue: Manual nailing can be exhausting; using a roofing nailer minimizes physical strain.

How to Choose the Right Roofing Nails

Material Compatibility: Ensure the nail material is compatible with the roofing material to prevent reactions and corrosion.

Weather Conditions: Opt for hot-dipped galvanized roofing nails for wet climates or stainless steel for coastal areas.

Shank Type: Smooth shank nails are easier to drive, while ring shank nails offer better grip and resistance to pull-out.

Head Style: Umbrella head roofing nails provide extra holding power for soft materials, while standard flat heads work well for metal sheets.

Conclusion

Choosing the right roofing nails is crucial for a secure and durable roof installation. Whether you need IBR roof nails, steel roofing nails, roof tile nails, or 4-inch roofing nails, understanding their unique properties and applications can help you make an informed decision.

Additionally, using a roofing nailer can improve efficiency and consistency in large projects. Prices of roofing nails depend on factors such as material, size, quantity, and market demand. Investing in high-quality nails, such as hot-dipped galvanized roofing nails, ensures longevity and protection against corrosion, ultimately leading to a sturdy and long-lasting roof.

For the best results, always choose roofing nails that meet industry standards and are suited to your specific roofing material and environmental conditions. Qingdao Witop Steel group are fully convinced that the good quality products assist the success of our customers. Expert team of our company always available to assist customers in choosing the required products of their interest.

Roofing Nails FAQ

1. What are roof nails used for?

Roof nails are primarily used to secure shingles, roofing felt, and other materials to wooden structures like roofs.

2. What materials are roof nails made from?

Roof nails are typically made from galvanized steel, stainless steel, copper, or aluminum for durability and rust resistance.

3. What types of roofing nails are available?

Common types include:

- Smooth Shank Nails – For general roofing tasks.

- Ring Shank Nails – Provide better grip and are ideal for high-wind areas.

- Screw Shank Nails – Offer maximum holding power for secure fastening.

4. What size roof nails should I use?

The nail length should penetrate the roofing material and extend at least 3/4 inch into the decking. Standard sizes range from 1 inch to 2 inches.

5. Are galvanized nails better for roofing?

Yes, galvanized nails are coated to resist rust and corrosion, making them ideal for roofing projects.

6. How many roofing nails do I need per shingle?

Typically, 4-6 nails per shingle are recommended, depending on local building codes and wind resistance needs.

7. Can roof nails be reused?

Reusing roof nails is not recommended as it can compromise the roof’s integrity and safety.

8. What’s the difference between roof nails and regular nails?

Roof nails have larger heads for better hold and are often galvanized for corrosion resistance.

9. How should I store roof nails?

Store them in a dry, cool place to prevent rust and corrosion.

10. Can roof nails be used for other projects?

While designed for roofing, they can also be used in fencing, siding, and some general construction tasks.

If you’d like more detailed explanations or tips, let me know! 😊