Product Introduction of PPGI Color Coated Steel Coil

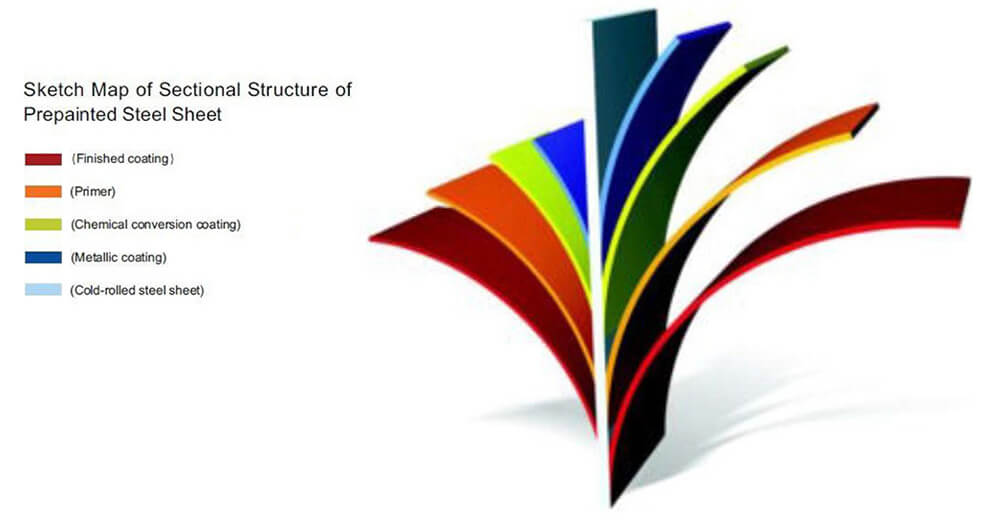

PPGI color coated steel coil have painting film to cover its surface and protect the steel from rusting, in addition to zinc coating film protection. The service life of prepainted steel coil is about 2 times longer than that of the galvanized steel coil.

Product Specification & Features

| PPGI Color Coated Steel Coil | ||

| Standard | JIS G 3312, EN 10169, ASTM A755 | |

| Grade | CGCC/CGCH,DX51D/DX52D | |

| Color | Client’s Sample Color or Any Ral Color (Down Load RAL Color Chart) | |

| Painting Brand | Nippon, Akzo-Nobel, KCC | |

| Top Side Painting Film | Primer | 5-10μm |

| Top Coating | 10–25μm | |

| Back Side Painting Film | Primer | 5-10μm |

| Top Coating | 10–25μm | |

| Surface Treatment | PVC Film, Wrinkle/Matt, Printed Surface | |

| Thickness | 0.12-2.00MM | |

| Width | 600-1250MM | |

| Zinc Coating | 40-275G/M2 | |

| Hardness | Softy, Semi Hard, Full Hard, G550 | |

| Coil Weight | 3-5MT/Coil or Customized | |

| Coil Inner Diameter | 508MM or 610MM | |

| Package | Standard Seaworthy Exporting Packing | |

| MOQ | 25MT | |

| Capacity | 8000MT/Month | |

| Transport Type | Vessel Container, Vessel Bulk ,Railway Container,Railway Wagon | |

| Loading Port | Tianjin, Qingdao, Ningbo, Shanghai and other port | |

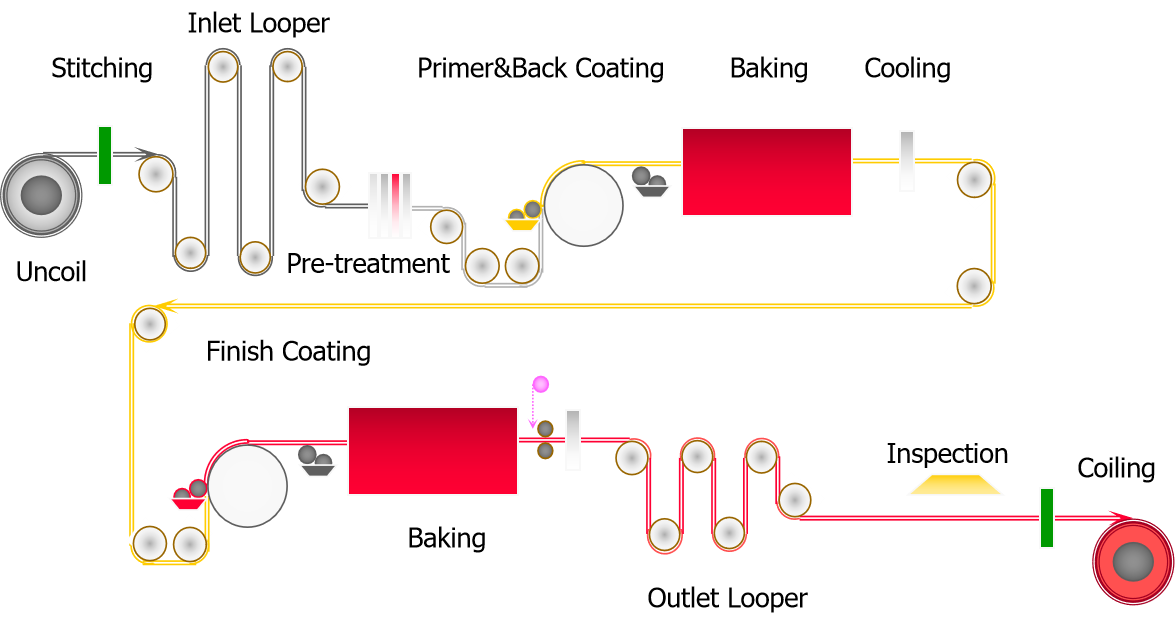

Prepainted steel Process Flow Chart

Prepainted Steel coil process flow

- Uncoil (Substrate Galvanized Steel or Galvalume Steel)

- Stitching

- Inlet looper

- Pre-treatment

- Primer and Back Coating

- Baking

- Cooling

- Top Coating/Double Coating

- Baking

- Outlet Looper

- Inspection

- Recoiler

Quality Control and Self-inspection of prepainted steel

WITOP steel have the advanced testing equipment and professional team. WITOP steel strictly control the quality on each step of production, including inspection on raw materials, product’s thickness and width test, zinc coating test, T-bend test, impact test, tensile test, color difference analysis during production, salt-spray test and package testing on exported steel coil, which ensures its integrated performance and quality.

Quality Test Machine

Product Application

PPGI color coated steel coil are used in construction industry, home appliance industry, electrical appliance industry and furniture industry. For example, color wave-shaped roofing sheet,color T-shaped roofing sheet, glazed tile, sandwich panel, fence, rolling shutter door, container wall and so on.

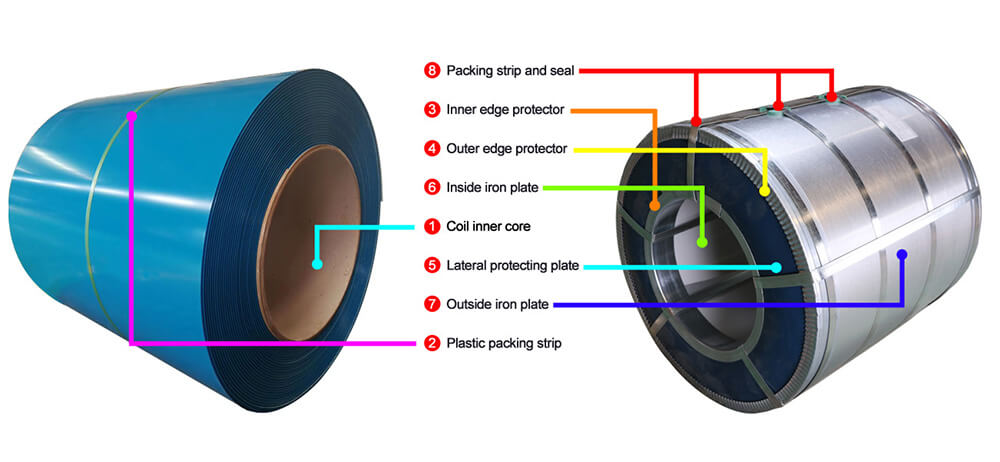

Product Package

Standard export package: 3 layers of packing, inner side is anti-water craft paper, PVC plastic film is the middle and outer side covered by at least 0.45mm thick steel sheet,wrapped by minimum seven steel strapping strips with lock catch.

In particular, WITOP steel places desiccant on the coil inner core side and on both lateral sides of the coil for bulk transportation to ensure that coils are delivered to clients in good condition.

Package can be customized as client’s requirements.

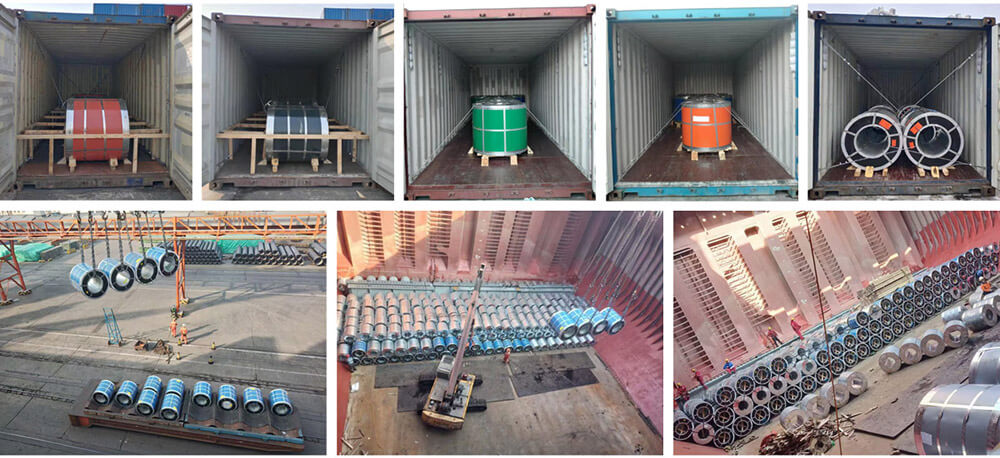

Loading and Fastening Steel Coil

WITOP steel have our own loading and fastening workers and team, which can fasten steel coils well in container and bulk based on ship line company. WITOP steel can guarantee goods well to every client.

Customer’s Feedback.

WITOP steel have exported PPGI color coated steel coil to Chile, Brazil, Peru, Bolivia, Uruguay, Somalia, Kenya, Tanzania, South Africa, Nigeria, Guinea, Ghana, Saudi Arabia, UAE, Kuwait, Iraq, Yemen, Singapore, Indonesia, Philippines, Thailand and other countries for twenty years. PPGI color coated steel coil have gained good reputation and wide appreciation throughout South America, Africa, Middle East, Middle Asia and Southeast Asia.

FAQ of PPGI Color Coated Steel Coil

1. What is PPGI steel coil?

PPGI is a abbreviation for pre-painted galvanized steel coil, also known as color coated steel coil.

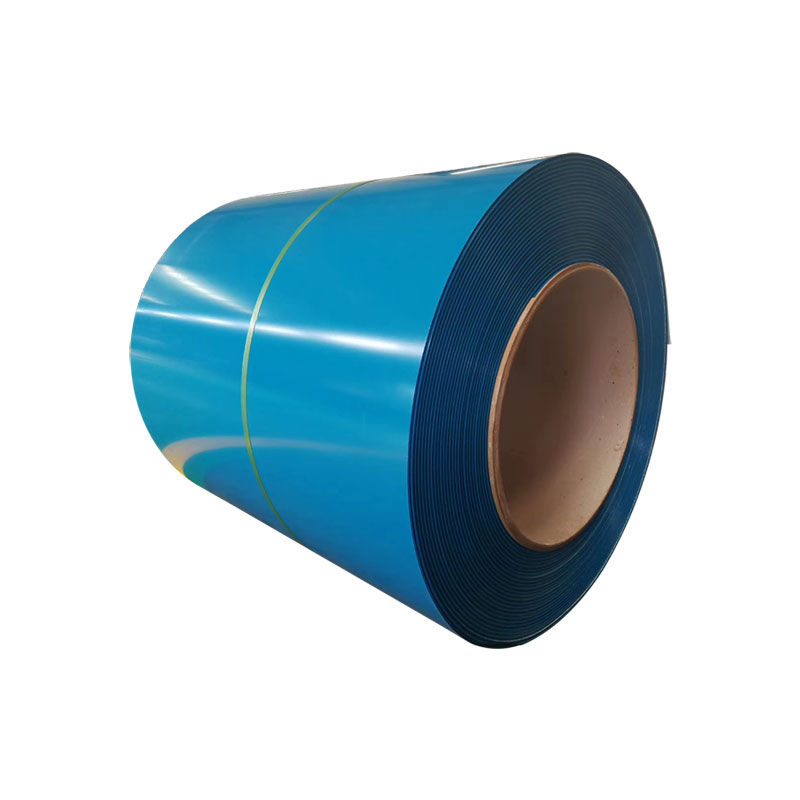

2. Which color are cheaper for prepainted galvanized steel coil price?

Generally, blue color series are cheaper, especially, sky blue(Ral5015) color are cheaper than other blue colors.

3. Which brand paint do you use?

Nippon, Akzo-Nobel and KCC brand paint.

4. Which paint style do you use?

PE, SMP,HDP and PVDF paint Prepainted Steel.

5. What is prepainted steel coil/sheets hs code?

The Harmonized System (HS) code for prepainted steel coil/sheet can vary depending on the specific type and form of the steel sheet. However, a common HS code is 7210.70 of prepainted steel.

6. What is ppgi coil full form?

PPGI is prepainted galvanized steel coil, also known as pre-coated steel, coil coated steel, color coated steel etc., typically with a hot dip zinc coated steel substrate. The term is an extension of GI which is a traditional abbreviation for Galvanized Iron.

7. What color to paint house with green roof?

White is classic with a green roof. Various shades of blue would look nice. A gray also would work, especially with white trim