Product Parameter (Specification)

| Electrolytic Tinplate Sheet | |

| Standard | JIS G 3303-2002, ASTM A623M-2002, DIN EN 10203-1991 |

| Grade | MR ,SPCC,SPHC,Q195, S08AL. |

| Material Origin | BAO(BAOWU) Steel |

| Tin Coating | 2.0/2.0, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4 /8.4 |

| Tin Weight | 1.1G/M2-8.4G/M2 |

| Surface Finish | Bright Finish, Stone Finish, Silver Finish, Matte Finish |

| Temper | T1, T2, T2.5, T3, T4, T5, DR-8, DR-7M |

| Thickness | 0.12-0.55MM |

| Width | 20-1250MM |

| Coil Weight | 3-5MT/Coil or Customized |

| Coil Inner Diameter | 508MM or 610MM |

| Package | Standard Seaworthy Exporting Packing |

| MOQ | 25MT |

| Capacity | 6000MT/Month |

| Transport Type | Vessel Container, Vessel Bulk ,Railway Container,Railway Wagon |

| Loading Port | Tianjin, Qingdao, Ningbo, Shanghai and other port |

| Delivery Time | 25-30 Days after Receiving the Deposit |

| Terms of Trade | EXW,FOB, CFR, CIF |

| Terms of Payment | TT and Irrevocable LC at Sight |

| Code | Classification | Specific Finishes |

| B | Bright Finish | The luster surface are provided by a flow-brightened tin coating on smooth finished steel base metal. |

| R | Stone Finish | The luster surface are provided by a flow-brightened grindstone-pattern tin coating on steel base metal. |

| S | Silver Finish | The luster surface are provided by a flow-brightened tin coating on a coarse dull finish steel base metal. |

| M | Matte Finish | A dull surface provided by an unmelted coating on dull finished steel base. |

Product Application

Electrolytic tinplate have the characteristics of corrosion resistance, non-toxicity, high strength and good ductility.

Packaging made of tinplate has good sealing, storage, light repellency, robustness, and unique metal decorative charm, which determines its wide coverage in the packaging container industry, making it an internationally common packaging material.

Electrolytic tinplate is widely used as a packaging material for food and beverages, grease cans, chemical cans, and other miscellaneous cans, to provide excellent protection of the physical and chemical properties of the contents. Tinplate cans can be used to fill juice, coffee, tea, and sports drinks, as well as cola, soda, beer, and other beverages. High workability of tinplate allows for many variations in its shape, whether high, short, large, small, square, or round, which can meet the diverse needs of the beverage packaging and consumer preferences. For example, chemical cans,food cans, tea cans and oil bucket, etc.

| Grade | Main Usage | |

| Food Grade

Cans |

Food Cans | fishery and agricultural products, etc. |

| Beverages Cans | juice, soft drinks, other beverages | |

| Industrial Grade Cans

|

Oil Cans | automobile oil, mechanical oil, etc. |

| Pails | Industrial containers for paint and oils | |

| Aerosol Cans | cosmetics, butane gas, pesticide, etc. | |

| Temper & Hardness & Applications | ||

| Temper | Hardness | Applications |

| T1 | 49±3 | nozzles,spouts,closures. |

| T2 | 52±3 | pie pans,closures,shallow drawn and specialized can parts. |

| T3 | 57±3 | battery can bodies,can ends and bodies,large diameter closures,crown caps. |

| T4 | 61±3 | can ends and bodies,crown caps and small screw closures. |

| T5 | 65±3 | Can ends and bodies for non corrosive products. |

| DR-8 | 73±3 | small diameter round can bodies and ends. |

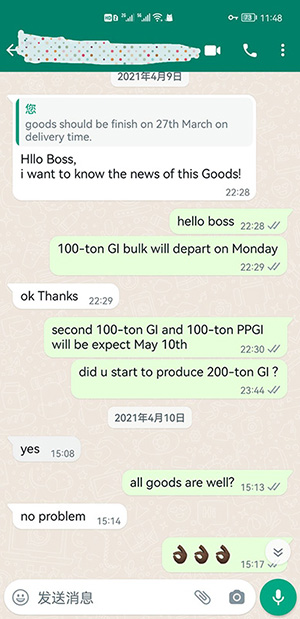

Main Market and Customer’s Feedback

Tinplate is mainly exported to Italy, Belgium, Spain, the United States, Saudi Arabia, the United Arab Emirates, Thailand, Mexico, South Africa, Malaysia, Vietnam, Philippines, Indonesia, Western Asia, Singapore, Australia, South Korea, and other countries.