DX51D Z100 Prime Hot Dipped Galvanized Steel Coil

DX51D+Z100 is BS EN 10346:2015 compliant. DX51D is a European standard, galvanized with 51 steel coil raw materials, equivalent to SGCC.

DX51D+Z means that the product is used for bending and profiling quality of flat steel cold forming, the substrate status is not specified, and the steel grade serial number 51, pure zinc coating, hot-dip galvanized steel products.

DX51D stands for galvanized steel sheet in coil. The first letter D means flat steel for cold forming, and X means hot rolled base material. Number 51 means the steel grade serial number. The Second D is the code for hot-dip galvanizing; Z Means the coating is pure zinc.

What means Z100?

Z100 means designating the nominal mass of pure zinc coating. A zinc coating mass of 100 g per Square Meter on both surfaces corresponds to a zinc coating thickness of about 7.0 um per surface.

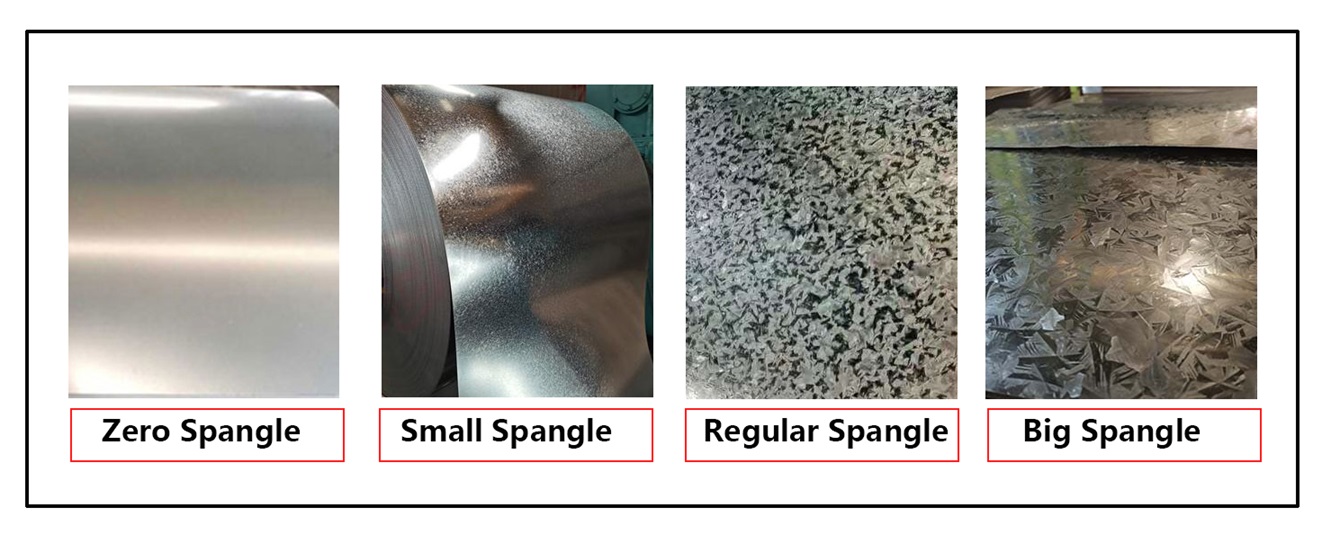

Spangle Types: Generally, zinc spangles are divided into four types:

Zero spangle, Small spangle, Regular spangle and Big spangle. The following are photos of the spangle comparison:

Advantages of DX51D Z100 Prime Hot Dipped Galvanized Steel Coil

It is should have a good appearance and should not have defects that are harmful to the use of the product, such as no plating, holes, cracks, scum, excessive thickness, scratches, chromic acid dirt, white rust, etc. Excellent strong surface oxidation resistance, enhanced rust and rust resistance.. It can prevent corrosion on the surface of the steel plate and extend its service life. And the galvanized sheet looks clean and more aesthetically pleasing, increasing the decorative effect.

Application of DX51D Z100 Prime Hot Dipped Galvanized Steel Coil

It is mainly applied in industries such as air conditioning and refrigerators. The rear panel of indoor air conditioning units, cabinet rear panel, indoor casing, and indoor casing are all made of galvanized sheet metal. In the working environment, these places often encounter strong oxidation conditions such as rain, sunlight, and hot air corrosion, so galvanized sheets are often chosen.

Thick galvanized patterned plates are mainly used in the construction, home appliances, automotive, and metallurgical industries. Among them, the construction industry is mainly used for roofs, doors and windows, rolling shutter doors, suspended ceiling keels, etc.; Household appliances such as refrigerators and washing machines; The automotive industry is mainly used for body casings, chassis, doors, fuel tanks, mudguards, etc.;The metallurgical industry is mainly used for steel window blanks, color coated plate substrates, etc.

FAQ of Prime Hot Dipped Galvanized Steel Coil

1.Is hot dipped galvanized steel same as galvanized?

Hot-dipped galvanized steel is a type of galvanized steel. Hot dipped galvanizing process is practical, and hot dipped galvanized product is very durable, versatile and highly corrosion-resistant.

2.What is the difference between G60 and G90 for galvanized steel?

G90 galvanized steel are coated by the coating weight of zinc 0.90 oz/ft^2 while G60 galvanized steel are 0.60 oz/ft^2. That is to say, G90 galvanized steel are coated by the weight of zinc 275g/m^2 while G60 galvanized steel are 180g/m^2.

Therefore, G90 galvanized steel are more 95g/m^2 zinc coating than G60 and then a longer service life.

3.What are galvanized steel coil used for?

Hot dipped galvanized steel coil are most produced to roofing sheet for construction and houses.

4.How are galvanized coils made?

Hot dipped galvanized steel coil are made from cleaning and heat-treating cold rolled coils and then are zinc coated from zinc pot. Through this process, cold rolled steel coil are plated with zinc for anti-rust.

5.How long will galvanized steel coil last?

The zinc coating of hot-dipped galvanized steel will last 10 to 30 years in the open environment. High humidity and temperature have less life time for galvanized steel coil.

6.Does galvanized steel rust?

Galvanized steel coil will take 10 year or more to rust, but it will eventually rust. Galvanized steel coil the layer of zinc on both sides. which can resit rust acts by preventing oxygen and water from the steel.