1. Brief Introduction

Prepainted Galvanized Steel (PPGI Sheets) sheets have become a preferable selection for various industrial, construction, and architectural applications. Known for their durability, aesthetic appeal, and resistance to corrosion, PPGI sheets offer a versatile solution for manufacturers, contractors, and designers alike.

In this blog post, we will explore the different types of PPGI products such as PPGI roof sheets, PPGI colour-coated sheets, as well as their pricing and applications. Whether you’re looking to understand the basics of PPGI or seeking more technical insights into PPGI panels and PPGI PUF panels, we’ve got you covered.

2. What Is PPGI?

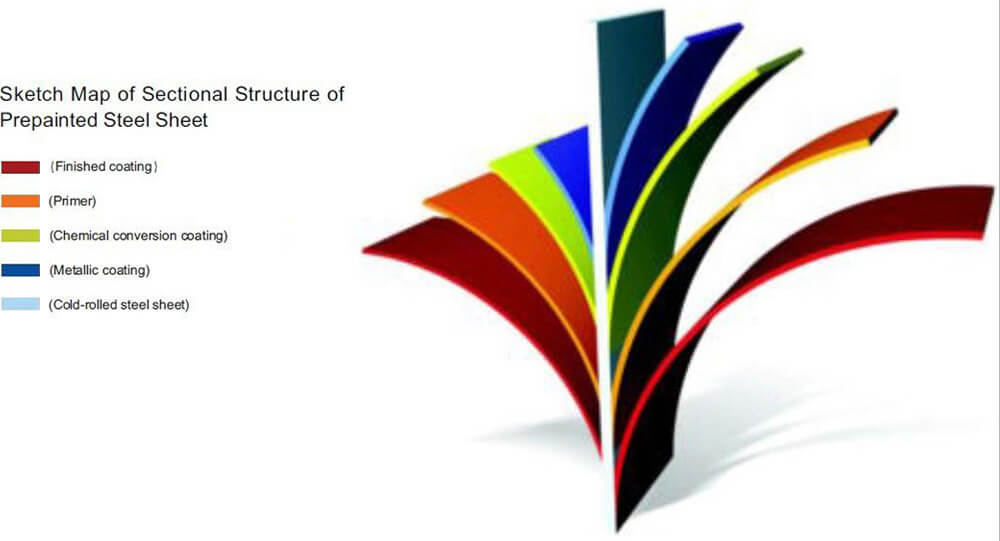

PPGI stands for Prepainted Galvanized Iron, a steel product that undergoes a galvanization process before being coated with a layer of paint or protective film. The underlying material is galvanized steel, which is steel that has been coated with a layer of zinc to enhance its corrosion resistance. The steel is then coated with a layer of paint, which can be a polyester, epoxy, or silicon-based coating, depending on the intended application.

3. Types of PPGI Sheets and Their Diverse Application

1. PPGI Steel Sheets

PPGI steel sheets are the most common form of this material. They are used in a wide range of applications, from roofing to wall panels. The prepainted coating gives them an added layer of protection against environmental elements, making them ideal for both outdoor and indoor uses.

PPGI sheets are known for their high strength-to-weight ratio, making them easier to handle and install than heavier alternatives like traditional steel.

- PPGI Roof Sheets

PPGI roof sheets are one of the most common uses for prepainted galvanized steel. They are often used in residential and industrial roofing projects due to their durability, long lifespan, and resistance to extreme weather conditions.

These roof sheets are available in a variety of profiles, including corrugated, ribbed, and flat sheets, to suit different aesthetic and structural requirements.

- PPGI Corrugated Sheets

Corrugated PPGI sheets are a popular choice for roofing and wall applications. Their wave-like structure adds strength while reducing the overall weight of the sheet. The corrugated profile also helps with water drainage, making it an excellent choice for roofing.

Due to their lightweight nature and ease of installation, PPGI corrugated sheets are widely used in both commercial and residential constructions.

- PPGI Colour-Coated Sheets

One of the major advantages of PPGI sheets is the range of color options available. These color-coated sheets are used in applications where appearance is important.

Available in various colors and finishes, PPGI color-coated sheets are frequently used in the construction of office buildings, factories, and warehouses. The paint layer can also be customized to suit specific environmental conditions, such as high UV exposure or coastal regions with high saltwater content.

- PPGI PPGL Sheets

PPGI PPGL (Prepainted Galvalume) sheets are similar to PPGI sheets, but they are coated with a mixture of aluminum and zinc, which provides even better corrosion resistance than standard galvanized coatings.

The additional aluminum content makes PPGL sheets more resistant to extreme heat and environmental degradation. As a result, PPGI PPGL sheets are often used in applications like industrial roofs and facades, where additional protection from the elements is required.

- PPGI PUF Panels

PPGI PUF panels are a type of sandwich panel made by combining PPGI sheets with an insulating polyurethane foam core. These panels are ideal for thermal insulation and are widely used in cold storage rooms, warehouses, and HVAC systems.

The combination of the prepainted galvanized steel exterior and the insulating foam interior provides superior insulation properties, which help in maintaining temperature control and energy efficiency.

PPGI Panels

PPGI panels are pre-painted steel sheets that come in large sizes and are commonly used for large-scale construction projects. These panels are often used as wall cladding or for roofing in factories, warehouses, and commercial buildings. The prepainted surface adds to their aesthetic value while ensuring they are protected from rust and corrosion.

4. Benefits of PPGI Sheets: Strong as SteelBenefits of PPGI Sheets: Strong as Steel

- Corrosion Resistance

- Aesthetic Appeal

- Durability

- Ease of Maintenance

- Lightweight

- Sustainability

5. Important Consideration in the selection of PPGI Sheets

- The amount and intensity of ultraviolet (UV) radiation: The amount and intensity of UV radiation to which the product is exposed is governed by the latitude of the location, the hours per year of sunlight, and the angle of exposure of the prepainted sheet.

Obviously, a low angle (flat) roof on a building located in a desert area in the low latitudes requires a primer and topcoat system that is very resistant to UV radiation to avoid premature fading, chalking and cracking. Conversely, UV radiation damage would be of much less concern for vertical wall cladding on a building located in a high-latitude, cloudy climate.

- The moisture contact time experienced: The moisture contact time refers to the length of time the cladding on roofs and walls is wet due to rain, high humidity, fog and condensation. Paint systems are not impervious to moisture. If they remain wet long enough, the moisture will eventually reach the substrate under any paint system, and corrosion will begin.

The amount of chemical contaminants, e.g., sulphur dioxide, chlorides, etc., present in the atmosphere will govern the corrosion rate. Some paint systems are more impervious to moisture than others.

- The acidity of the rain and the presence of chlorides (near sea coast locations)

- Localized effects:Local or micro-climate effects that need to be taken into account include wind direction, pollution fallout from industrial plants and marine environments. Gaseous and particulate exhaust emissions can have a serious effect on paint systems.

Within 3 miles of heavy industry, corrosivity can range from moderate to heavy depending on the wind direction and local weather conditions.

If prepainted buildings are located close to the sea coast (within 300 yards), the effects of salt water can be severe. Significant effects can be experienced up to 3 miles inland and farther, depending on offshore winds.

If the corrosiveness of a proposed building site is not obvious, an investigation of the local area can be helpful.

Data from environmental monitoring stations can provide information on precipitation, humidity and temperature. An examination of unwashed surfaces in protected exposures can indicate whether particulate fallout from industry, roads, marine salts, etc., is a concern.

Paint suppliers have the knowledge and experience to recommend paint systems for specific environments.

6. How Much Do PPGI Sheets Cost?

The price of PPGI sheets varies depending on several factors, such as the thickness of the sheet, the type of coating, the colour, and the size. Typically, PPGI sheet prices range from $700 to $1500 per ton, depending on the supplier and market conditions.

For instance, PPGI colour-coated sheets or PPGI corrugated sheets may be priced slightly higher due to the additional processing involved. The cost of PPGI PUF panels can also vary, as the insulating foam core adds to the overall price.

It’s important to consider factors like transportation costs, bulk discounts, and material quality when evaluating pricing. Purchasing from reputable suppliers can also help ensure that you’re getting the best value for your investment in PPGI products.

7. Conclusion

PPGI sheets are a versatile and reliable material for a variety of applications, offering a combination of strength, aesthetic flexibility, and long-lasting performance. Whether you’re looking for PPGI roof sheets, PPGI colour-coated sheets, PPGI steel sheets, or even PPGI PUF panels, this material offers a robust and cost-effective solution for modern construction, manufacturing, and industrial needs.

By understanding the different types of PPGI sheets and their unique benefits, you can make an informed decision about which product best suits your needs. Whether you’re upgrading your roof, designing a new building, or working on an industrial project, PPGI products can provide the strength, durability, and aesthetic appeal you need to bring your vision to life.

What is Galvanized Iron sheet HS code?

Galvanized Steel Sheet HS Code 721490