Introduction

Metal sheets are a versatile material used in countless industries, from construction to manufacturing. Whether you’re building a home, creating a DIY project, or working on an industrial task, understanding the different types of metal sheets, their applications, and how to select the right sheet for your project is crucial.

Sheet metal workers use pieces of thin steel, aluminum, or other alloyed metal in both manufacturing and construction. Sheet metal products include heating and air conditioning ducts, rain gutters, outdoor signs, and siding.

In this guide, we’ll explore various types of metal sheets, including aluminum sheet metal, stainless steel sheet metal, and galvanized sheet metal, and provide you with an overview of sheet metal gauges, sheet metal roofing, cost and factors need to consider while purchasing one of the most common sizes for metal sheets –4×8 sheet of metal and other related topics.

What Are Metal Sheets/ Sheet Metal?

Sheet metal is metal that is formed into thin, flat pieces. Sheet metal is generally produced in sheets less than 6 mm. It is one of the fundamental forms used in metalworking and can be cut and bent into a variety of different shapes. Thicknesses can vary significantly.

Metal sheets are produced by rolling, hammering, or pressing metal into a uniform thickness. These sheets are available in a range of metals, including steel, aluminum, copper, stainless steel, and galvanized steel, and are often used in construction, manufacturing, and automotive industries due to their durability, strength, and flexibility.

The thickness of metal sheets is often measured using a unit known as gauge, which is critical for determining the sheet’s strength and suitability for different applications. Let’s dive deeper into the various types of metal sheets available and their uses.

Types of Metal Sheets: Let’s dive deeper

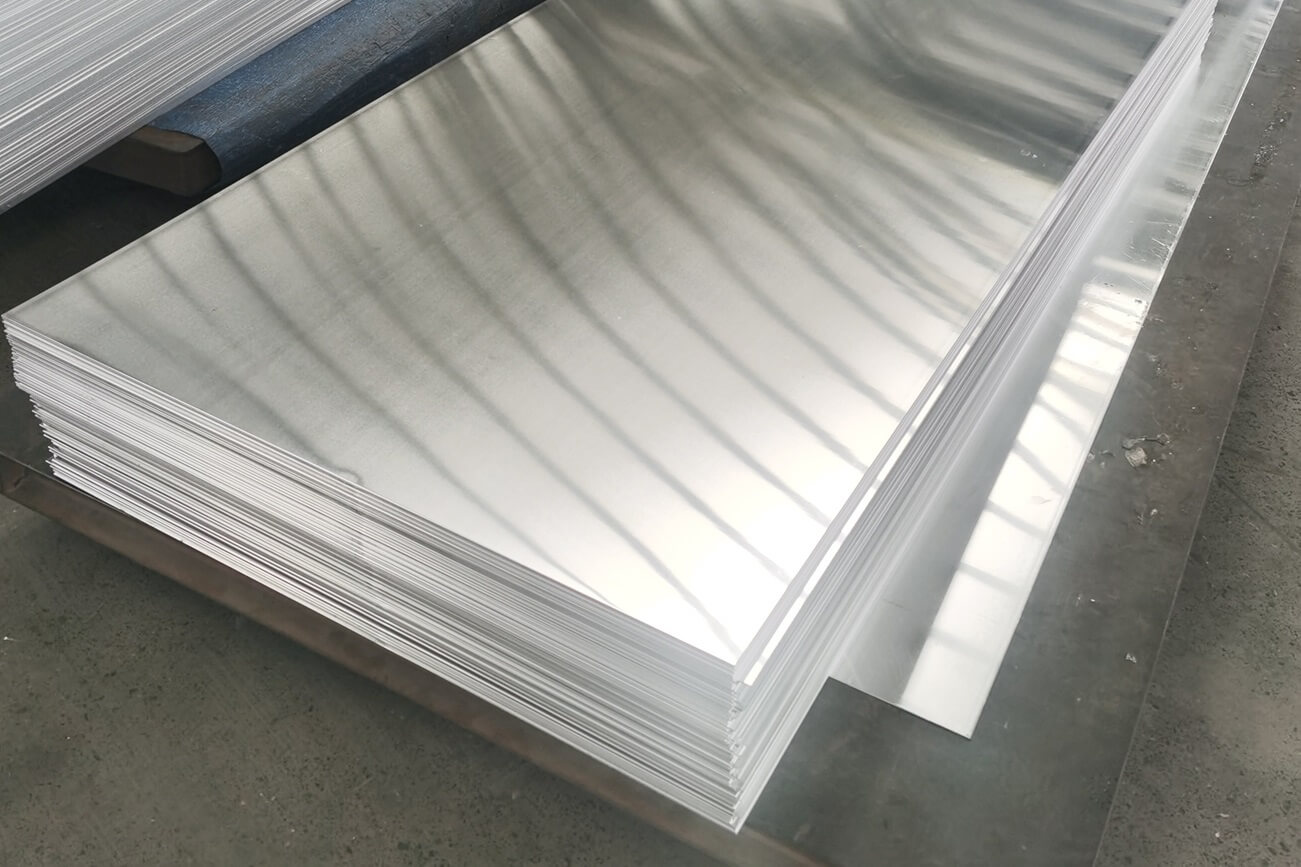

Aluminum Sheet Metal

- Aluminum sheet metal is a popular choice for many industries due to its light weight, high strength-to-weight ratio, and resistance to corrosion. It is often used in applications where both durability and low weight are necessary. For example, aluminum sheets are commonly found in the automotive industry, where they are used to make body panels, as well as in construction for roofing and siding.

One of the primary benefits of aluminum sheet metal is its excellent corrosion resistance, making it ideal for environments that are exposed to moisture or chemicals. Aluminum can also be easily shaped, making it a versatile option for a variety of projects.

Stainless Steel Sheet Metal

- Stainless steel sheet metal is widely used in industries that require materials to withstand harsh environments, such as in food processing, medical equipment, and construction. It has high resistance to rust and corrosion, making it ideal for applications that are exposed to high temperatures or chemicals.

Stainless steel is available in a variety of grades, each offering different properties. 304 stainless steel, for instance, is one of the most common grades used in sheet metal because of its excellent corrosion resistance and weld-ability.

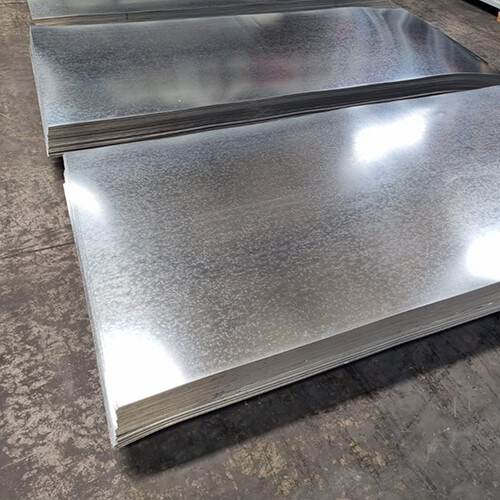

Galvanized Sheet Metal

- Galvanized sheet metal refers to steel sheets that have been coated with a layer of zinc to protect them from rust and corrosion. This type of metal is commonly used in construction and roofing due to its ability to withstand the elements. The zinc coating prevents moisture from coming into contact with the steel, which helps extend the life of the metal.

Galvanized metal is often used in metal roofing and metal roof sheets because it is durable, affordable, and resistant to rust. It’s also used in outdoor furniture, automotive parts, and other products that need to stand up to weathering.

Steel Sheet Metal

Steel sheet metal is a strong and durable option, suitable for a variety of applications. It’s commonly used in the construction of building structures, automotive manufacturing, and in the production of household appliances. Steel sheet metal is available in different thicknesses, which makes it adaptable for different types of construction and fabrication tasks.

Sheet Metal Gauge Chart

When choosing the right metal sheet for your project, it’s important to understand the sheet metal gauge system. Gauge is a measurement of the thickness of a metal sheet, and a lower gauge number corresponds to a thicker sheet. Understanding how the gauge system works is essential for selecting the right metal sheet for your needs.

Here’s a basic sheet metal gauge chart to help you understand the relationship between gauge number and sheet thickness:

| Gauge | Thickness(inches) | Thickness(mm) |

| 10 | 0.134 | 3.4 |

| 12 | 0.105 | 2.7 |

| 14 | 0.078 | 2.0 |

| 16 | 0.063 | 1.6 |

| 18 | 0.048 | 1.2 |

| 20 | 0.035 | 0.9 |

| 22 | 0.030 | 0.8 |

| 24 | 0.020 | 0.5 |

The gauge of the sheet you choose depends on the specific requirements of your project. For example, 4×8 metal sheets intended for construction or industrial use will often be made of thicker materials, like 10-gauge steel, to provide strength and durability.

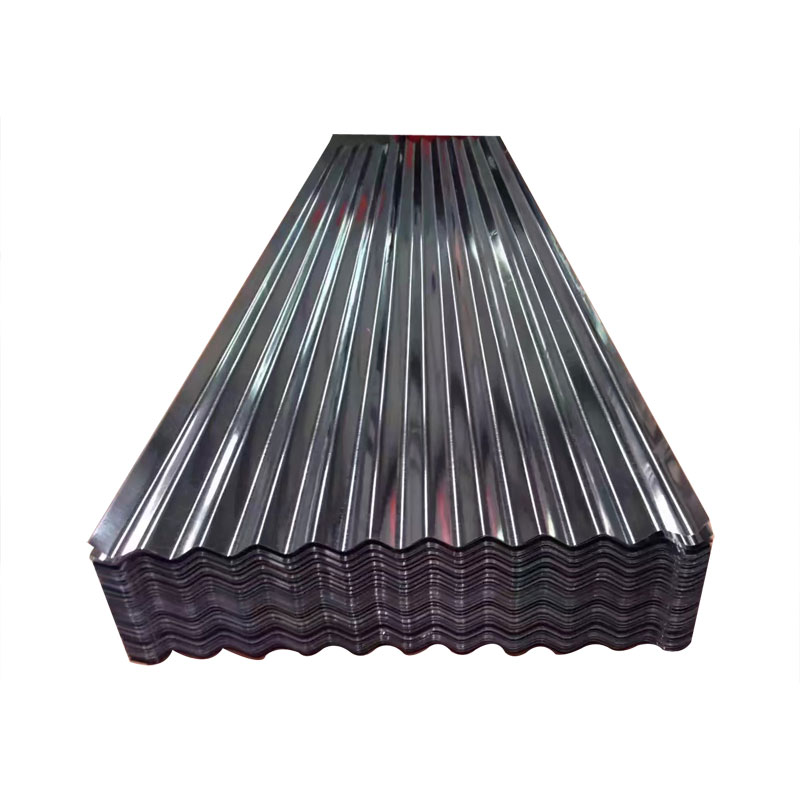

Sheet Metal Roofing: A popular choice

Sheet metal roofing is a popular choice for both residential and commercial buildings because of its long lifespan, energy efficiency, and aesthetic appeal. Metal roof sheets come in various materials, including galvanized steel, aluminum, and copper, each with its unique properties.

- Galvanized steel is commonly used for roofing because it is cost-effective, durable, and provides a protective barrier against the elements. The zinc coating on galvanized sheets ensures that the roofing material resists rust and corrosion.

- Aluminum roofing is lightweight and highly resistant to corrosion, making it ideal for coastal areas with high humidity or saltwater exposure.

- Copper roofing is known for its longevity and distinctive aesthetic. Copper sheets develop a natural patina over time, adding to their charm.

When considering sheet metal roofing, it’s important to choose the right metal sheet thickness to ensure that the roof can withstand the weather conditions in your area.

4×8 Metal Sheets: What You Need to Know

One of the most common sizes for metal sheets is the 4×8 sheet of metal. This size is highly versatile and can be used in a variety of projects, from roofing to wall panels to custom metalwork. A 4×8 sheet metal typically measures 4 feet by 8 feet in size, but the thickness can vary depending on the material and the application.

The price of 4×8 sheet metal can vary greatly depending on the material and thickness you choose. On average, 4×8 sheet metal prices range from $50 to $200 per sheet, but this can fluctuate based on the type of metal (e.g., aluminum, stainless steel, galvanized steel) and its thickness.

4×8 Sheet Metal Prices: Factors to Consider

When buying 4×8 sheet metal, several factors can influence the price:

- Material Type: Aluminum tends to be more expensive than steel, while stainless steel is often the most expensive option due to its high corrosion resistance and strength.

- Gauge/Thickness: Thicker sheets generally cost more. For example, a 10-gauge steel sheet will cost more than a 20-gauge steel sheet.

- Finish: Some metal sheets come with coatings or finishes (like galvanized or painted sheets), which can increase the cost.

Before purchasing, it’s a good idea to compare prices from different suppliers and consider whether the sheet will need to be custom cut or processed in any way.

Sheet Metal Shear: Cutting Metal Sheets

If you need to cut metal sheets for your project, a sheet metal shear is an essential tool. A sheet metal shear allows you to cut through metal sheets quickly and accurately, whether you’re working with a 4×8 sheet metal or larger pieces. There are manual, electric, and pneumatic versions of metal shears available, depending on your needs.

When cutting metal sheets, always wear appropriate safety gear, including gloves and eye protection, to prevent injury from sharp edges and flying metal shards.

Conclusion

Understanding the different types of metal sheets, their thicknesses, and their applications is essential for anyone working with metal in construction, manufacturing, or DIY projects. From aluminum sheet metal to stainless steel sheet metal, and from galvanized sheet metal to metal roof sheets, there are a wide variety of options to suit your needs. By considering the gauge chart, choosing the right material for your project, and understanding the costs and cutting processes involved, you can ensure that your project is completed successfully and efficiently.

When buying 4×8 metal sheets or any other dimension metal sheets, take time to compare prices, consider the thickness and material that best suits your needs, and invest in the right tools to cut and install your metal sheets.

Qingdao Witop Steel group is a first-class steel enterprise in China. You can always reach our company for expert option while buying sheet metal of your choice. Whether you’re working on a new roof, building a custom metal project, or repairing equipment, metal sheet is a reliable and durable material that will serve you well for years to come.