JIS G3321

JIS G3321

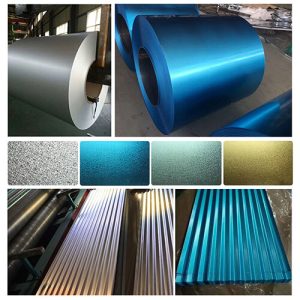

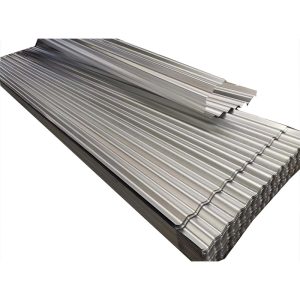

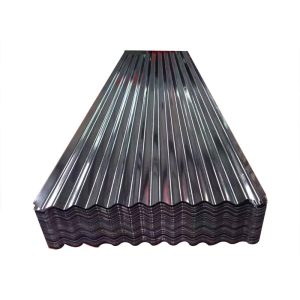

JIS G3321 Standard specifies requirements for hot-dip 55 % aluminium-zinc alloy-coated steel sheets (hereafter referred to as sheets), hot-dip 55 % aluminium-zinc alloy-coated steel strips (hereafter referred to as coils), and corrugated steel sheets manufactured by processing sheets into the shapes and dimensions specified in JIS G 3316 (hereafter referred to as corrugated sheets)

This Standard specifies requirements for hot-dip zinc-coated steel sheets (hereafter referred to as sheets), steel strips (hereafter referred to as coils), and corrugated steel sheets manufactured by processing sheets into the shapes and dimensions specified in JIS G 3316 (hereafter referred to as corrugated sheets).

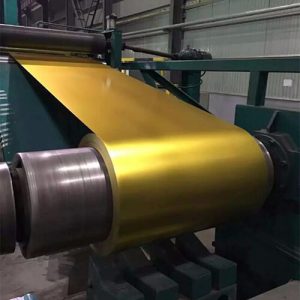

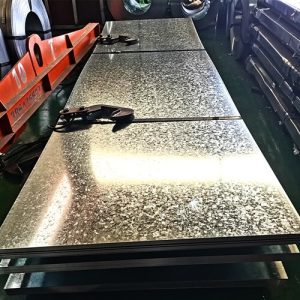

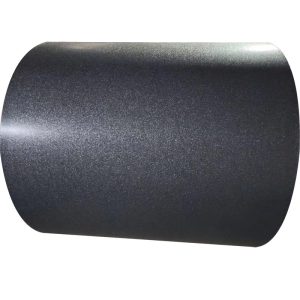

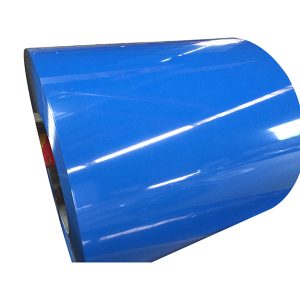

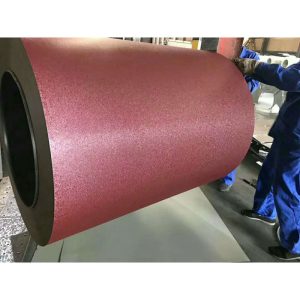

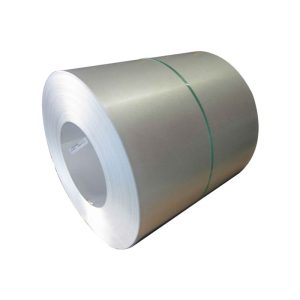

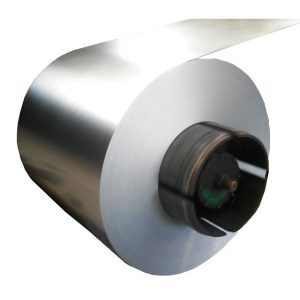

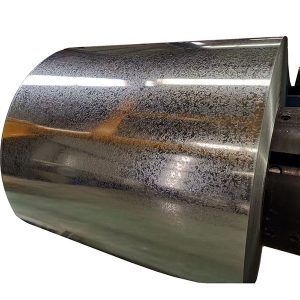

Hot-dip aluminum-zinc-silicon steel, also called alu-zinc, galvalume (GL for short), is a steel sheet made of aluminum(Al 55%), zinc (Zn 43.5%), and silicon (Si 1.5%) alloy on both sides. The surface of galvalume coil has small and uniform aluminum-zinc spangle, bright color, and high surface hardness. Hot dipped galvalume steel coil can be coated with various colors of anti-finger print (AFP) semi permeable films.

Hot dipped galvalume/aluzinc steel coil have better corrosion resistance, heat resistance, and heat reflection properties, compared to traditional galvanized steel products. GL galvalume steel coil are widely used in industries such as home appliances, construction, structures, and electrical appliances.

JIS G3321 Equivalent

Chinese standard: GBT 14978

European standard: EN10215

American standard: ASTM A792M

What is SLGCC?

SGlCC steel is a soft forming quality hot dip galvalume steel coil. SGLCC is a material grade and designation defined in JIS G 3321 standard. JIS G 3321 is a Japanese material standard for hot dip galvanized steels. The commercial quality hot dip galvanized steel is a type of steel that can be made after galvanizing a coil of SPCC cold rolled material.

JIS G3321 Specification

Based on Hot-roll Steel Sheet:

| Grade | Thickness Range(mm) | Application |

| SGLHC | 1.60 ~ 2.30 | Commercial |

| SGLH400 | High strength commercial | |

| SGLH490 |

Based on Cold-roll Sheet:

| Grade | Nominal Thickness | Application |

| SGLCC | 0.24 ~ 2.3 | Commercial Hard |

| SGLCD | 0.27 ~ 1.6 | Drawing |

| SGLCDD | 0.40 ~ 1.6 | Deep Drawing |

| SGLC400 | 0.25 ~ 2.3 | Structural Quality |

| SGLC440 | ||

| SGLC490 | ||

| SGLC570 | 0.19 ~ 2.0 |

JIS G3321 Chemical Composition

| Grade | C | Mn | P | S |

| SGLHC | 0.15max. | 0.80max. | 0.05max. | 0.05max. |

| SGLH400 | 0.25max. | 1.70max. | 0.20max. | 0.05max. |

| SGLH490 | 0.30max. | 2.00max. | 0.20max. | 0.05max. |

| SGLCC | 0.15max. | 0.80max. | 0.05max. | 0.05max. |

| SGLCD | 0.10max. | 0.45max. | 0.03max. | 0.03max. |

| SGLCDD | 0.08max. | 0.45max. | 0.03max. | 0.03max. |

| SGLC400 | 0.25max. | 1.70max. | 0.20max. | 0.05max. |

| SGLC440 | 0.25max. | 2.00max. | 0.20max. | 0.05max. |

| SGLC490 | 0.30max. | 2.00max. | 0.20max. | 0.05max. |

| SGLC570 | 0.30max. | 2.50max. | 0.20max. | 0.05max. |

JIS G3321 Mechanical properties

Tensile test characteristics

Based on Hot-Roll Sheet(units:%):

| Grade | Yield strength | Tensile strength | Elongation % |

| N/mm2 | N/mm2 | ||

| SGLHC | – | – | – |

| SGLH400 | 295 Min | 400 Min | 18 Min |

| SGLH490 | 365 Min | 490 Min | 16 Min |

NOTE 1 For SGLHC, a yield point or proof stress of 205 N/mm2 or over and a tensile strength of 270 N/mm2 or over may be used.

NOTE 2 1 N/mm2 = 1 MPa

Based on Cold-Roll Sheet (units:%):

| Grade | Yield strength | Tensile strength | Elongation % | ||||

| N/mm2 | N/mm2 | Thickness | |||||

| 0.25-0.4MM | 0.4-0.6MM | 0.6-1.0MM | 1.0-1.6MM | 1.6-2.3MM | |||

| SGLCC | – | – | – | – | – | – | – |

| SGLCD | – | 270 Min | – | 27 Min | 31 Min | 32 Min | 33 Min |

| SGLCDD | – | 270 Min | – | 29 Min | 32 Min | 34 Min | 35 Min |

| SGLC400 | 295 Min | 400 Min | 16 Min | 17 Min | 18 Min | 18 Min | 18 Min |

| SGLC440 | 335 Min | 440 Min | 14 Min | 15 Min | 16 Min | 18 Min | 18 Min |

| SGLC490 | 365 Min | 490 Min | 12 Min | 13 Min | 14 Min | 16 Min | 16 Min |

| SGLC570 | 560 Min | 570 Min | – | – | – | – | – |

NOTE 1 For SGLCC, a yield point or proof stress of 205 N/mm2 or over and a tensile strength of 270 N/mm2 or over may be used.

NOTE 2 1 N/mm2 = 1 MPa Note a) The sheets and coils of SGCD4 shall be free from stretcher strain marks when being formed, for a period of six months after manufacture.

Thickness Tolerances

Tolerances on product thickness Tolerances on product thickness

| Thickness MM | Width MM | |||

| Under 630 | 630-1000 | 1000-1250 | 1250-1400 | |

| Under 0.25 | 0.04 | 0.04 | 0.04 | 0.04 |

| 0.25-0.40 | 0.05 | 0.05 | 0.05 | 0.06 |

| 0.40-0.60 | 0.06 | 0.06 | 0.06 | 0.07 |

| 0.60-0.80 | 0.07 | 0.07 | 0.07 | 0.07 |

| 0.80-1.00 | 0.07 | 0.07 | 0.08 | 0.09 |

| 1.00-1.25 | 0.08 | 0.08 | 0.09 | 0.1 |

| 1.25-1.60 | 0.09 | 0.1 | 0.11 | 0.12 |

| 1.60-2.00 | 0.11 | 0.12 | 0.13 | 0.14 |

| 2.00-2.30 | 0.13 | 0.14 | 0.15 | 0.16 |

Coating Mass

The coating applied shall be of equivalent thickness on both surfaces.

Design Coating Mass Table

| Design Coating Mass | Average Triple-Spot Test | Sing-Spot Test |

| AZ70 | 70 | 60 |

| AZ90 | 90 | 76 |

| AZ120 | 120 | 102 |

| AZ150 | 150 | 130 |

| AZ170 | 170 | 145 |

| AZ185 | 185 | 160 |

| AZ200 | 200 | 170 |

This is the main description about the JIS G3321 production standard. I hope it will be helpful to you know about the JIS G3321 of Hot dipped galvalume steel coil or Aluzinc Steel Coil. If you are looking for Steel suppliers or Looking for other Steeel products, Welcome to contact us at any time and we will prefer to provide more service.