JIS G3312

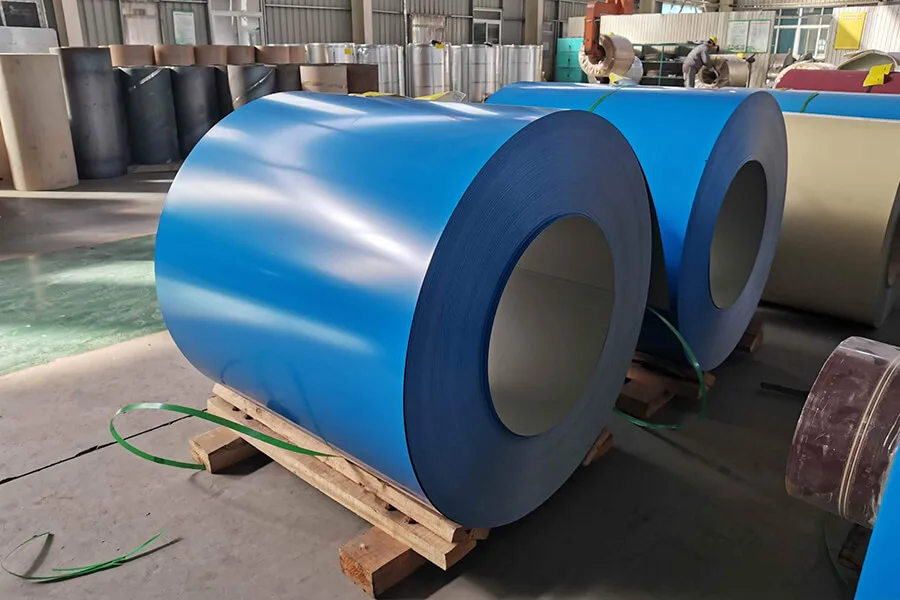

JIS G3312 is the production standard for Japanese Prepainted hot-dip zinc-coated steel sheets and coils. PPGI color coated steel coil have painting film to cover its surface and protect the steel from rusting, in addition to zinc coating film protection. The service life of PPGI is about 2 times longer than that of the galvanized steel coil.

This Japanese Industrial Standard specifies the prepainted hot-dip zinc-coated steel sheets and coils, produced by coating and baking durable synthetic resin paint uniformly on either one or both surfaces of hot-dip zinc-coated steel sheets and coils, using cold-reduced base metal specified in JIS G3302.In this case, the term “sheets” includes not only flat sheets but also sheets with corrugation of specified shape and dimensions given in JIS G 3316.

JIS G3312 Equivalent

Chinese standard: GBT 12754

European standard: EN10169

American standard: ASTM A755M

What is SGCC and CGCC Steel?

SGCC steel is a soft-forming quality hot dip galvanized steel and designation defined in JIS G 3302 standard. CGCC is a Japanese material standard JIS G 3312 of Prepainted hot-dip zinc-coated steel sheets and coils. The commercial quality Prepainted galvanized steel is a type of steel that can be made after painted coating steel coil of galvanized steel sheet in coil.

JIS G3312 Specification

The durability of paint coatings of JIS G 3312

shall be classified into three classes, and their grade shall be as given below:

| Grade | Nominal Thickness | Application | Substrate Grade |

| CGCC | 0.25 ~ 1.6 | Commercial | SGCC |

| CGCH | 0.11 ~ 1.0 | Commercial Hard | SGCH |

| CGCD1 | 0.40 ~ 1.6 | Drawing | SGCD1 |

| CGC340 | 0.25 ~ 1.6 | Structural Quality | SGC340 |

| CGC400 | SGC400 | ||

| CGC440 | SGC440 | ||

| CGC490 | SGC490 | ||

| CGC570 | 0.25 ~ 1.6 | SGC570 |

JIS G3312 Paint coating durability

The sheet and coil shall be subjected to the durability test given in the below Table. The salt spray test shall be carried out in accordance with no defects. except for slight blistering and rust on the test piece, shall be found on the test piece as a result of this test having been continued for the duration of time specified.

Salt spray test The salt spray test shall be as follows:

A test piece shall be 50 mm or more in width and 100 mm or more in length.

The testing method shall comply with JlS Z 2371.

Dew-cycle type accelerated weathering test The dew-cycle type accelerated weathering test shall be as follows:

A test piece shall be 50 mm or more in width and 100 mm or more in length.

The testing method shall comply with the dew-cycle type weathering tests specified in (Weathering test) of JIS Z 9117.

| JIS G 3312 Durability Test | ||

| Classification of Durability | Duration of salt spray test | Duration of dew-cycle type accelerated weathering test |

| Class 1 & 2 | 200h-500h | – |

| Class 3 | – | 1500h |

Remarks

1. For the sheet and coil for roofing for which the quality is guaranteed for one side only, the duration of the salt spray test for the reverse side shall be 150h.

2. For Class 3 in the classification of paint coating durability, the symbol of coating mass Z27 or more shall be applied to the substrate for prepainting.

Caution for testing

The tests require the following cautions:

Since the durability and physical properties of the sheet and coil are affected by environmental conditions and by paint coating flaws incurred in handling, haircracks on processed surfaces, etc., testing shall be conducted on flat sheets with normal surfaces.

The temperature for tests on physical properties shall be the normal temperatures (5°C to 35°C)specified in JlS Z 8703.

JIS G3312 Physical properties of paint coatings

JIS G3312 Physical properties

| Item | Commercial,hard (CGCH) Structural(CGC570) |

Commercial, Drawing, (CGCC) (CGCD1)Structural(CGC340,CGC400,CGC440,CGC490) |

Physical properties |

| Bending adhesion | – | 0 | No peeling on the outer sur-face of the bent portion less than 7mm from each side edge of the test piece |

| Paint film hardness | 0 | 0 | No scratch marks on the paint film |

| Impact resistance | – | 0 | No peeling |

| Adhesion | 0 | – | No irregularities on the tested portion |

Remarks:

Bending adhesion shall be applied for the sheet and coil using a non-alloyed type substrate for prepainting. It shall be regarded as a reference test for sheets and coils using an alloyed type substrate for prepainting.

Thickness Tolerances of JIS G 3312

Tolerances on product thickness (applicable to SGHC)

| Thickness | Width | ||

| Under 630MM | 630-1000MM | 1000-1250MM | |

| under 0.25 | ±0.08/0.03 | ±0.08/0.03 | ±0.08/0.03 |

| 0.25-0.40 | ±0.09/0.04 | ±0.09/0.04 | ±0.09/0.04 |

| 0.40-0.60 | ±0.10/0.05 | ±0.10/0.05 | ±0.10/0.05 |

| 0.60-0.80 | ±0.11/0.06 | ±0.11/0.06 | ±0.11/0.06 |

| 0.80-1.0 | ±0.11/0.06 | ±0.11/0.06 | ±0.12/0.07 |

| 1.0-1.25 | ±0.12/0.07 | ±0.12/0.07 | ±0.13/0.08 |

| 1.25-1.6 | ±0.13/0.08 | ±0.14/0.09 | ±0.15/0.10 |

| 1.6 | ±0.15/0.10 | ±0.16/0.11 | ±0.17/0.12 |

Width and Length Tolerances

Width Tolerance: 7MM

Length Tolerance: 15MM

Test of JIS G3312

Sampling of test specimens

The sampling of test specimens for the bend, pencil hardness, impact, and cross-scoring tests shall comply with the requirements, Specimens shall be taken from products of the same quality, dimensions,

coating mass, and color as stated below.

For corrugated sheets, test specimens shall be taken from flat sheets prior to corrugation.

1. For continuously paint-coated coils or cut length from continuously paint-coated coils, one test specimen shall be taken from each 50 t or its fraction.

2. For sheets manufactured by prepainting the substrates being cut to a specified length, one test specimen shall be taken from each 3000 sheets or its fraction.

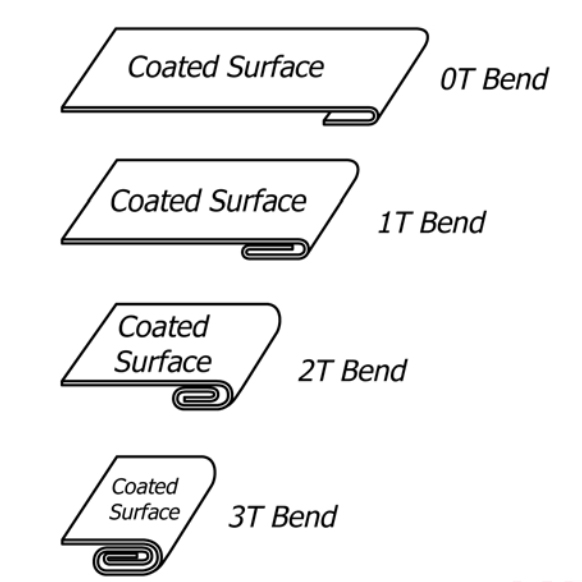

Bent Test of JIS G3312

The bend test shall be as follows:

1. The test piece shall have a width of 75 mm to 125 mm and a length suited for the test. Unless otherwise specified, one test piece shall be cut out of each test specimen paralleled to the rolling direction of the base metal.

2. By referring to the internal spacing of the bend shown in Table 17, the test piece shall be bent manually with a vise or like devices at right angles to the longitudinal direction of the piece, as shown in the Below pictures. When a hand vise is not available, other suitable means of testing may be adopted.

| Grade | Bend Angle | Thickness | Internal Spacing of Bend |

| CGCC | 180 Degree | 0.4 or under | 2 Sheet of Thickness |

| Over 0.4 up to 1.6MM | 3 Sheet of Thickness | ||

| CGCH | – | - | - |

| CGCD1 | 180 Degree | Over 0.4 up to 1.6MM | 2 Sheet of Thickness |

| CGC340 | 180 Degree | 0.4 or under | 2 Sheet of Thickness |

| Over 0.4 up to 1.6MM | 3 Sheet of Thickness | ||

| CGC400 | 180 Degree | 1.6MM or Under | 3 Sheet of Thickness |

| CGC440 | 180 Degree | 0.4MM or Under | 4 Sheet of Thickness |

| CGC490 | 180 Degree | Over 0.4 up to 1.6MM | 5 Sheet of Thickness |

| CGC570 | - | - | - |

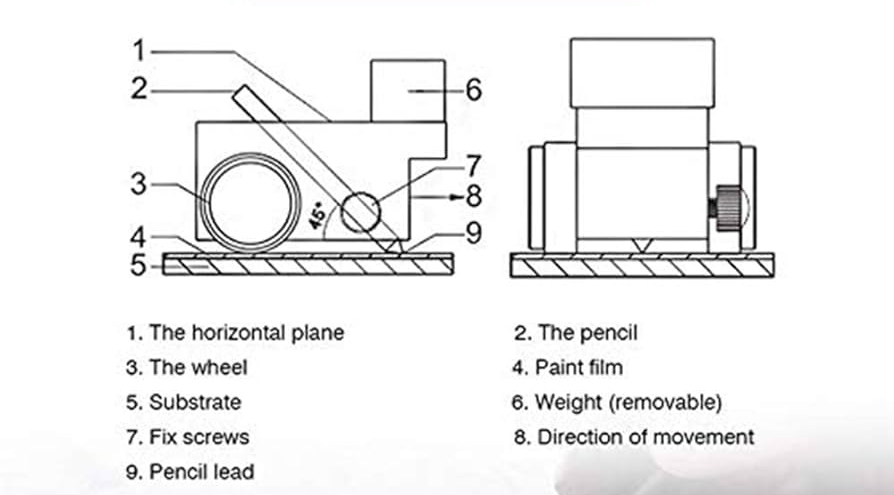

Pencil hardness test of JIS G3312

The pencil hardness test shall be as follows:

1. A pencil equal or superior to ordinary grade as specified in JIS S 6006 and having the hardness given in the below Table shall be used. For commercial and drawing qualities, pencil hardness symbols other than those given above may be used as agreed upon between the purchaser and manufacturer.

Pencil Hardness

| Durability | Hardness |

| Class 1 | H |

| Class 2 | H |

| Class 3 | F |

2. The pencil shall be sharpened so as to expose about 3 mm of lead. While being held at right angles to an abrasive paper of No. 400 or finer which has been laid on a hard, flat surface, the point of the lead shall be made to draw a continuous circle gently and thus be ground down so as to obtain a flat surface with sharp edges at the tip.

The tip of the lead shall be ground flat before reuse for each test.

3. Holding the prepared pencil at about 45 degrees to the surface of the tests specimen, straight lines shall be drawn with it in the direction shown in below pictures with the load being applied of about 10 N. The lines shall be not less than 20mm in length and not less than three in number.

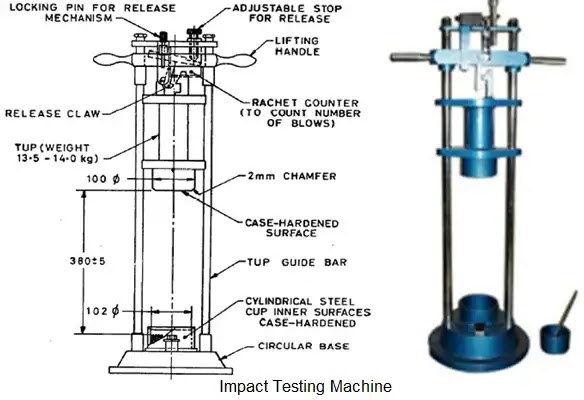

Impact test of JIS G3312

The impact test shall be as follows:

1. A weight shall be dropped onto a test face from a Du Pont-type impact tester, as shown below pictures.

2. The mass of the weight shall be 500 ± 1 g, and the radius of the impact point shall be 6.35+0.03 mm.

3. The weight shall be dropped from a height of 500 mm above the test piece.

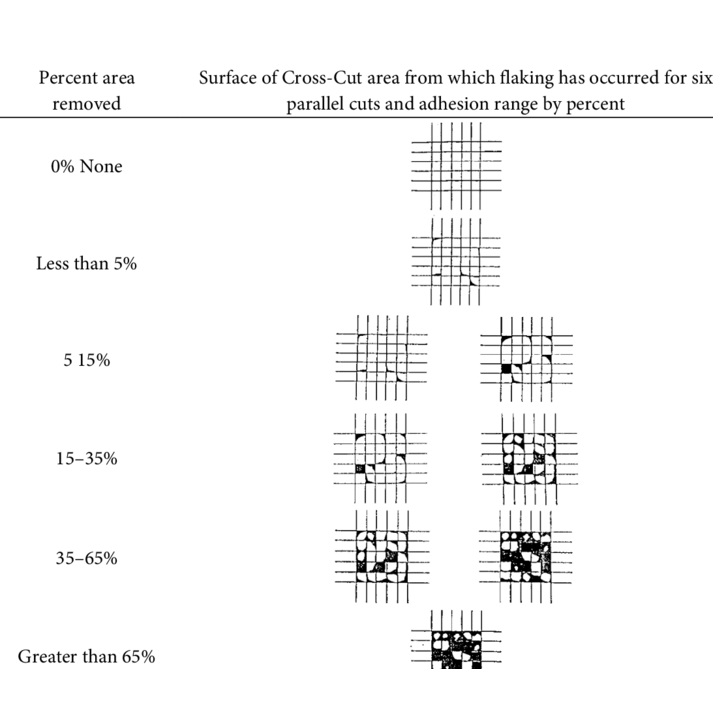

Cross-scoring test of JIS G3312

The cross-scoring test shall be as follows:

1. Straight lines shall be scored with a safety razor blade or other pointed objects so as to reach the surface of the coating through the paint film and to form squares.

2. Eleven straight lines shall be scored crosswise at right angles, at intervals of 1mm.

Caution for testing of JIS G3312

The tests require the following cautions:

1. Since the durability and physical properties of the sheet and coil are affected by environmental conditions and by paint coating flaws incurred in handling, haircracks on processed surfaces, etc., testing shall be conducted on flat sheets with normal surfaces.

2. The temperature for tests on physical properties shall be the normal temperatures(5°C to 35°C)specified in JlS Z 8703.

This article introduces the technical parameters of JIS G3312 production standards. It is hoped that the introduction of this article will help to better understand the knowledge of color-coated coil products. When you need color-coated coil products, I suggest you prioritize and consider Witop Steel. Witop Steel is a steel manufacturer specializing in the production of galvanized, galvalume, color-coated coils and color steel tiles. If you need to find other steel suppliers, you are welcome to contact us and we will be happy to provide you with professional help.