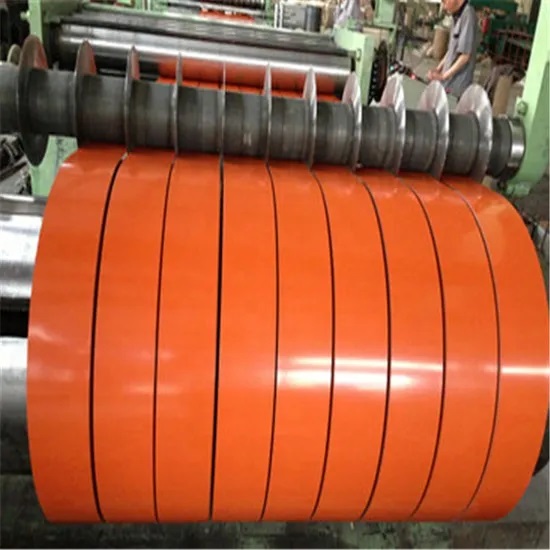

Printed color coated plate is a type of building material produced by a special printing process. Its technology mainly involves the interaction between patterns and colored ink to form a unique pattern effect. The specific process is as follows:

Firstly, the substrate of the printing coating board needs to be properly stored with starch glue, and then a special hard wear-resistant mold is used to imprint the patterns on the glue, achieving the effect of air being discharged from the mold to the glue surface, thus floating the patterns on the board surface. At this point, there is a relatively flat pattern on the plate surface.

Subsequently, the 45m long production line further underwent a color ink coating process to obtain various colored patterns, usually beautiful and realistic wood, marble, granite, and other patterns. The key point of this step is to ensure that the color ink is downloaded to the accurate location, without causing pattern distortion due to missing or misprinting.

The printed coating plate enters the curing chamber and cures the color ink evenly at an appropriate temperature within a certain period of time, meeting the excellent requirements of decorative panel strength, wear resistance, and environmental protection.

This is the basic process of manufacturing printed color coated boards, and it is also the key to ensuring their aesthetics, durability, environmental protection, and other performance aspects.