1. Precautions for the selection of color coated steel sheet:

Color coated steel sheet is selected according to the end usage purpose, which is suitable for usage and cost-effective at the same time. Color coated steel sheet mainly considers the external atmospheric environment and the relatively closed internal environment. At the same time, it is considered to the specific environment such as acid, alkali, salt, humidity, light, ventilation, etc. for the actual usage.

2. Precautions for storage, transportation and handling of color-coated steel sheet:

1. The color-coated steel sheet(PPGI/PPGL) should be stored in a dry and ventilated environment, and should be kept away from acid, alkali, salt and other organic solvents and corrosive media;

2. In the process of transportation and loading and unloading, the color-coated sheet should prevent the intrusion of rain, snow, mist, paint film damage, pollution, bumping, extrusion, etc., which may cause surface corrosion;

3. Steel coil should be transported according to the original package and it cannot be disassembled at will.

3. Precautions for the processing and installation of color-coated steel sheet:

1. According to the design requirements, it is principal to follow the principle of selecting the same manufacturer and the same batch of products for the same project to avoid affecting the appearance due to color differences;

2. If the product is found to have an abnormal appearance and quality after receiving the goods, stop using it and contact the supplier as soon as possible.

3. Avoid low-temperature processing (should be above 7°C) for color-coated steel sheets, select suitable mechanical processing color-coated steel sheets, and check the quality indicators such as product surface and adhesion during processing and use. If there are quality problems, the reasons should be found out and take measures. After the measures are taken, it can continue to be processed and used;

4. In the process of processing and installation, the color-coated steel sheet should avoid cutting high-temperature metal powder adhesion, sliding between layers of color tile profiles, collision, application of mechanical tools, hard sole shoes and other damage to the product protective coating. And waterproof and anti-corrosion material sealing fixing bolts are selected; if surface damage occurs during processing and installation, it should be repaired with special repair paint in time to ensure the service life of the color-coated steel sheet;

5. After the color-coated steel tile is installed, the surface and incision should be kept clean and away from corrosive media such as cement, acid, alkali and salt;

6. Long-term direct sunlight and other ultraviolet light irradiation are forbidden in the process of transportation, storage, processing and installation of epoxy back paint for color-coated steel sheets;

7. As a color-coated sheet for roofing, the installation slope is recommended to be no less than 10 degrees. After the color-coated steel roof is installed, the surface should be kept clean to ensure the service life of the color-coated steel sheet;

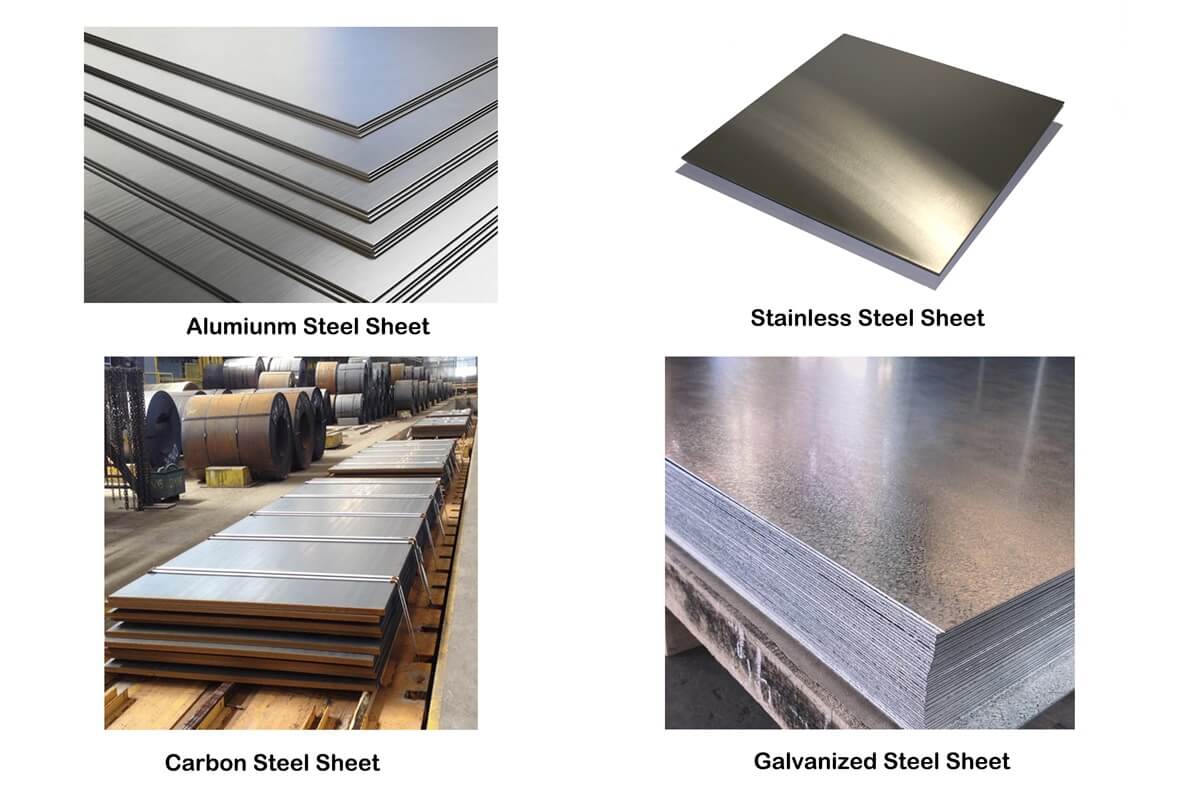

Witop’s color-coated steel sheet use high-quality hot-dip galvanized sheet/ hot-dip aluminum-zinc sheet/aluminum sheet processed by hot-rolled steel coil of state-owned steel mills, and use world-renowned Akzo Nobel, Nippon and PPG paint manufacturers. The types of coatings include ordinary polyester (PE) , Silicon Modified Polyester (SMP), High Durability Polyester (HDP), Polyvinylidene Fluoride (PVDF), etc..

Color-coated steel sheet rely on the company’s advanced management, technical research and development, physical inspection as the support, with excellent processing performance, durability and rich and diverse colors. Witop Steel can provide individualized small-color product development and engineering technical services according to user’s needs.