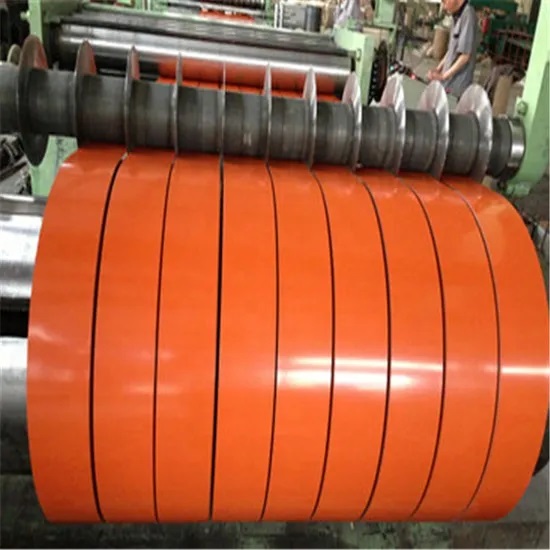

1. Precautions for the selection of pre-painted steel coil:

Pre-painted steel coil are selected according to the end usage in order to meet the requirements and at the same time cost-effective. The selection of pre-painted steel coil can be judged separately in the specific environment, mainly considering the external atmospheric environment and the relatively internal environment(rural atmosphere, urban atmosphere, industrial atmosphere, and marine atmosphere). Meanwhile, acid, alkali, salt, humidity, light, ventilation, etc. are considered specific to actual usage.

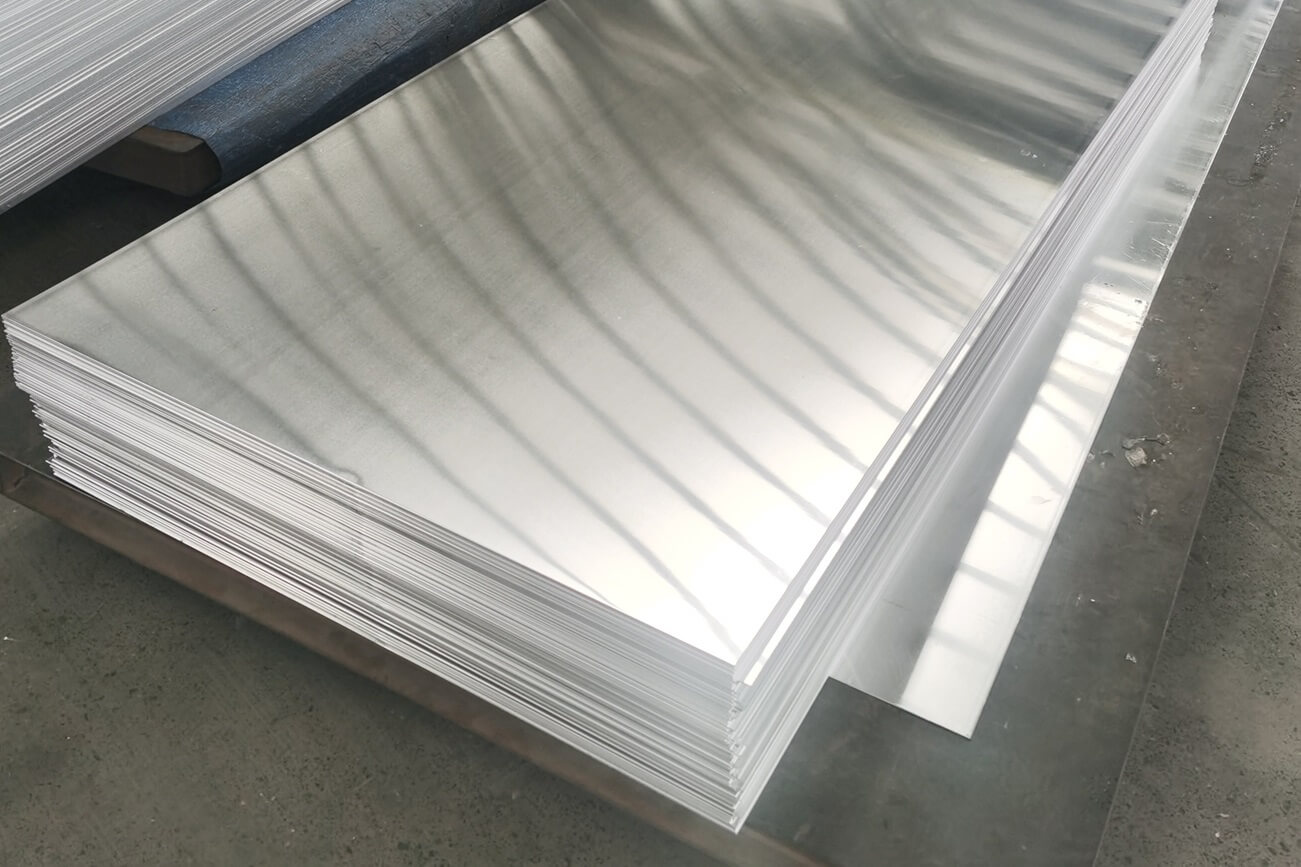

2. Precautions for storage, transportation, loading and unloading of pre-painted steel coil:

(1). Pre-painted steel coil are stored in a dry and ventilated environment, and should be kept away from organic solvents and corrosive media such as acids, alkalis, and salts;

(2). During transportation, loading and unloading, pre-painted steel coil should prevent from the intrusion of rain, snow, fog, paint film damage and pollution, bumps, extrusions, etc., which cause paint surface corrosion;

(3). The product should be transported in the state with original standard package.

3. Precautions for processing and installation of pre-painted steel coil:

(1). According to the design requirements, it is principle to select the same manufacturer and same batch of products for the same project, avoiding color differences that affect the appearance;

(2). Processing of pre-painted steel coil should be above 7℃(avoid low-temperature ) to choose suitable mechanical processing pre-painted steel coil and to check the product surface, adhesion and other quality indicators during processing. If there are quality problems, you should find out the cause and take measures. After the measures are taken, the processing can be continued;

(3). Pre-painted steel coil should avoid paint coating damage during processing, installation and application; if the surface damage, special coatings should be used to repair them in time to ensure the service life of color-coated panels;

(4). After the color roof installed, the surface and cutting point of pre-painted steel coil should be kept clean, away from cement, acid, alkali, salt and other corrosive media;

(5). Epoxy back paint for pre-painted steel coil is forbidden to long-term direct sunlight and other ultraviolet light during transportation, storage, processing and installation;

(6). As pre-painted steel coil for roofing sheet, the installation slope is recommended to be no less than 10 degrees. After the pre-painted steel roofing sheet is installed, the surface should be kept clean to ensure the service life of the pre-painted steel sheet;

The pre-painted steel coil rely on the company’s advanced management, technical research and development, and physical testing as support. Pre-painted steel product have excellent processing performance, durability and a rich variety of colors. Witop steel can provide individualized small color product development and project usage according to clients’ needs. Pre-painted steel product are widely used in industries such as construction, home appliances, home improvement, and specific environments.