Color coated steel coil (PPGL) is a common building material that has characteristics such as aesthetics, good weather resistance, and corrosion resistance, making it widely used in the construction industry. However, in order to improve the quality of galvanized sheets, manufacturers of color coated sheets need to take some measures.

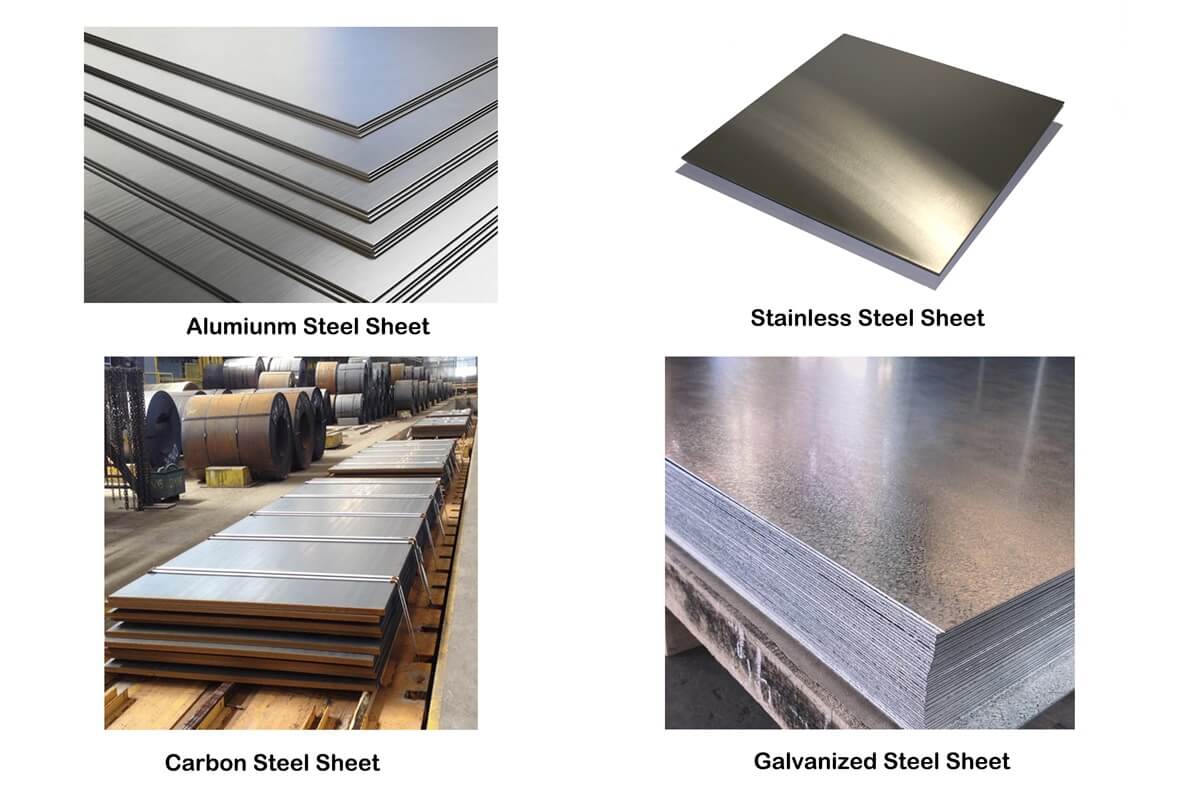

Firstly, in the production process, color coated coil manufacturers should pay attention to the selection of raw materials. Choosing high-quality polyester coatings and suitable galvanized sheets is crucial for improving the quality of galvanized sheets. Polyester coatings should have good adhesion and weather resistance, which can effectively prevent coating detachment and rusting. Galvanized sheet metal should have good corrosion resistance to ensure the stability of the galvanized layer.

Secondly, manufacturers of color coated panels should strengthen production process control to ensure that each link meets standard requirements. For example, in the coating process, the thickness and uniformity of the coating should be strictly controlled to avoid uneven thickness of the coating layer. At the same time, attention should be paid to controlling temperature and humidity during the coating process to ensure the quality of the coating.

In addition, color coated sheet manufacturers can also take some special treatment measures to improve the quality of galvanized sheets. For example, surface treatment can be applied to galvanized sheets to increase the adhesion between the coating and the substrate. At the same time, appropriate coating methods can be selected, such as spraying, rolling coating, etc., to ensure that the coating evenly covers the galvanized sheet.

It is worth mentioning that in the production process, color coated plate manufacturers should also pay attention to quality inspection. By establishing an effective quality inspection system, timely identification and resolution of production problems can be achieved to improve the quality of galvanized steel sheets. At the same time, sampling inspection and product testing can be carried out to ensure that the product meets relevant standards and requirements.

In summary, to improve the quality of galvanized sheet, manufacturers of color coated sheet need to choose high-quality raw materials, strengthen production process control, take special treatment measures, and conduct quality inspections. Only in this way can high-quality polyester color coated steel coil be produced to meet market demand.