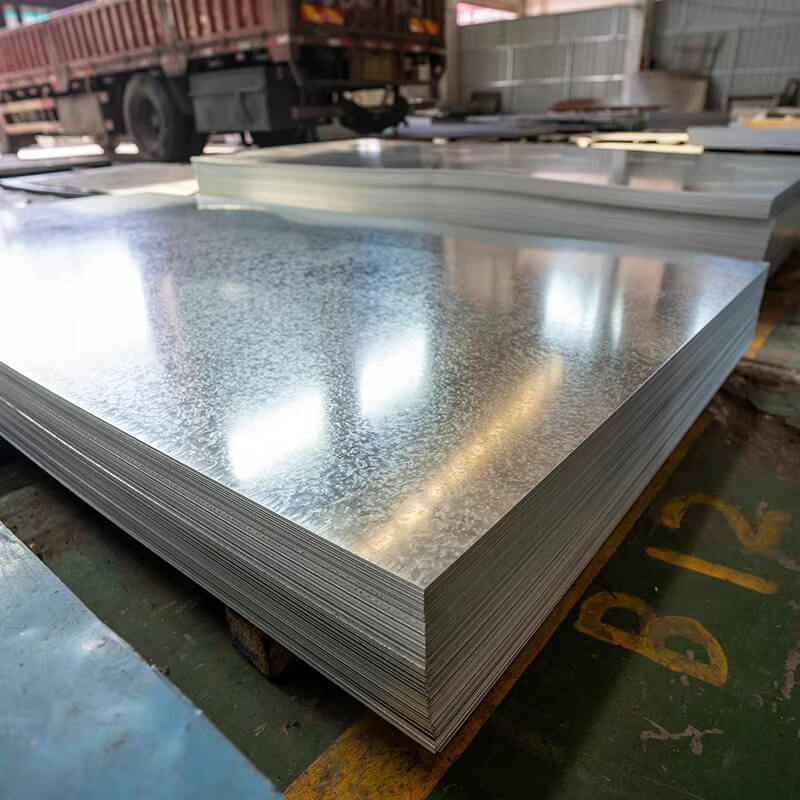

Galvanized sheet is a type of steel sheet that has been coated with a layer of zinc to protect it from corrosion. There are several classifications of galvanized Steel sheet based on the thickness of the zinc coating, the type of steel used, and the application for which it is intended. Understanding these classifications is crucial for selecting the right type of galvanized steel sheet for a particular project.

Galvanizing is an economical and effective rust prevention method commonly applied, and about half of the world’s zinc production is used in this process. Galvanized Iron sheet refers to a steel plate coated with a layer of zinc on its surface. Galvanized Steel sheet is a steel plate that is coated with a layer of metallic zinc to prevent corrosion on the surface and extend its service life. This type of zinc coated steel plate is called galvanized Steel sheet or GI Sheet.

1. Alloy and composite galvanized steel plate.

It is a steel plate made of zinc and other metals such as aluminum, lead, zinc, etc., and even composite plating. This type of steel plate has both rust resistance and good coating performance;

2. Hot dip galvanized steel plate.

A thin steel plate that is immersed in a molten zinc bath to adhere a layer of zinc to its surface. At present, the main production method is continuous galvanizing, which involves continuously immersing rolled steel plates in a molten zinc plating bath to produce galvanized steel plates;

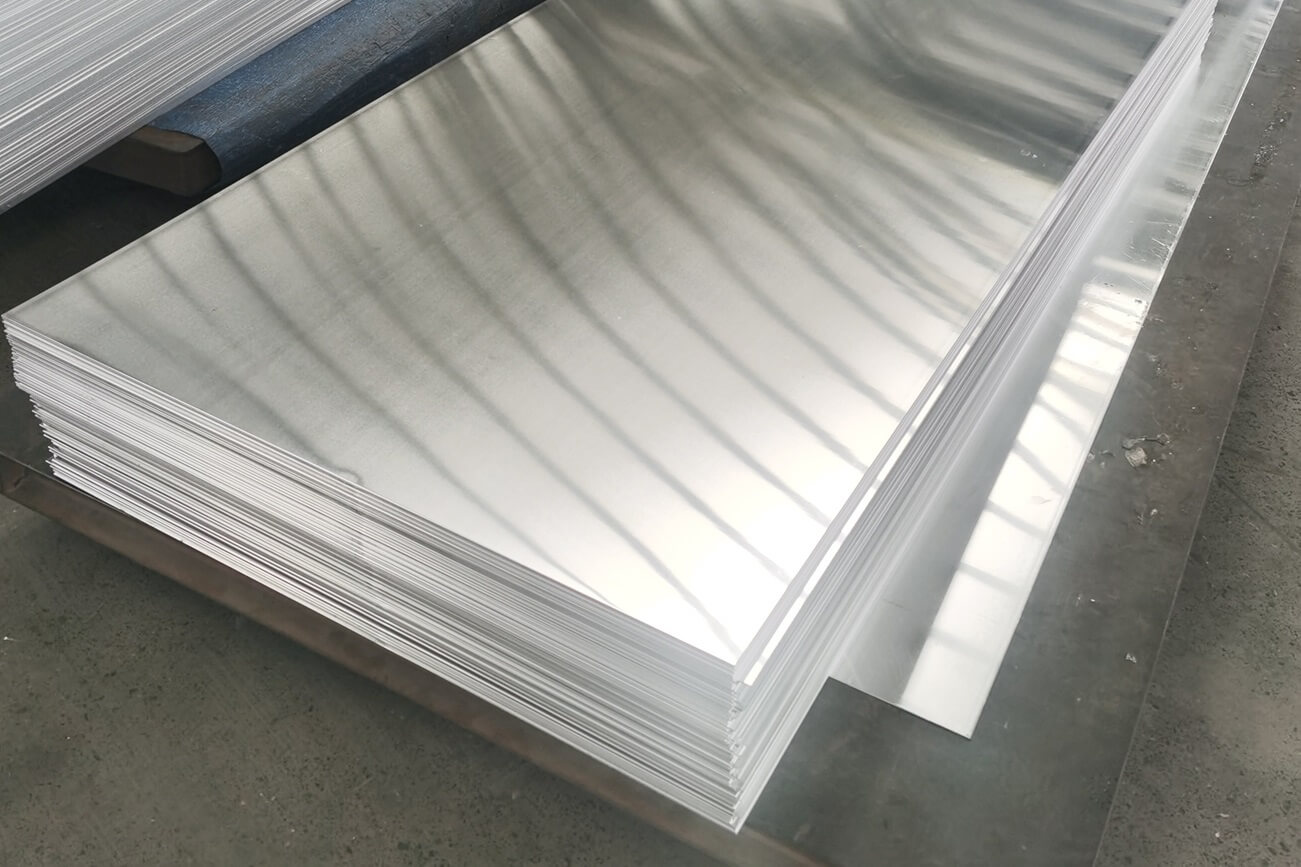

One common classification of galvanized steel sheet is based on the thickness of the zinc coating. This thickness is typically measured in grams per square meter, with thicker coatings offering better corrosion resistance. The three main classifications of galvanized sheet based on coating thickness are G90, G60, and G30. G90 galvanized sheet has a coating weight of 270 grams per square meter, making it the most corrosion-resistant option. G60 and G30 galvanized sheets have lighter coating weights of 180 and 90 grams per square meter, respectively, and are suitable for less demanding applications.

Another important classification of galvanized iron sheet is based on the type of steel used. Galvanized steel sheets can be made from a variety of steel grades, each with its own mechanical properties and corrosion resistance. Common grades used for galvanized sheet include A653 CS Type B, A653 SS Type 316, and A653 HSLAS Type B. A653 CS Type B is a standard commercial-grade steel with good formability and weldability. A653 SS Type 316 is a high-strength steel with excellent corrosion resistance, making it suitable for outdoor applications. A653 HSLAS Type B is a high-strength low-alloy steel that offers superior strength and toughness.

In addition to coating thickness and steel grade, galvanized sheet can also be classified based on its application. Galvanized sheet is commonly used in a wide range of industries, including construction, automotive, and manufacturing. In construction, galvanized sheet is often used for roofing, siding, and structural components. In the automotive industry, galvanized sheet is used for body panels, chassis components, and exhaust systems. In manufacturing, galvanized sheet is used for appliances, furniture, and metal containers. Understanding the intended application of the galvanized sheet is important for selecting the right grade and coating thickness.

3. Alloyed galvanized steel plate.

This type of steel plate is also manufactured using the hot dip method, but immediately after being removed from the groove, it is heated to around 500 ℃ to form an alloy film of zinc and iron. This galvanized sheet has good coating adhesion and weldability;

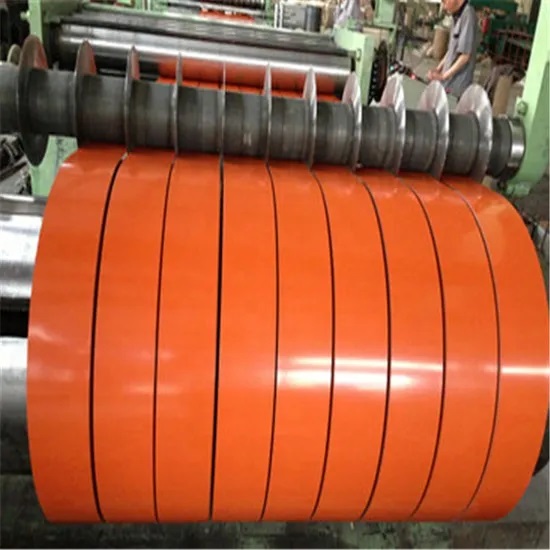

4. Electro-galvanized steel plate.

Manufacturing this galvanized steel plate using electroplating method has good processability. But the coating is thinner and its corrosion resistance is not as good as that of hot-dip galvanized sheet;

5. Single sided and double sided differential galvanized steel plates.

Single sided galvanized steel plate refers to a product that is only galvanized on one side. In terms of welding, coating, rust prevention treatment, processing, etc., it has better adaptability than double-sided galvanized sheet. To overcome the disadvantage of not coating zinc on one side, there is another type of galvanized sheet coated with a thin layer of zinc on the other side, namely double-sided differential galvanized sheet.

Overall, the classification of galvanized steel sheet is essential for ensuring the proper performance of the material in various applications. By considering factors such as coating thickness, steel grade, and application, engineers and designers can select the right type of galvanized sheet for their needs. Whether it is for a corrosive outdoor environment or a high-strength structural application, there is a classification of galvanized iron sheet that meets the specific requirements of the project. With a thorough understanding of these classifications, professionals can make informed decisions about the selection and use of galvanized sheet in their projects.