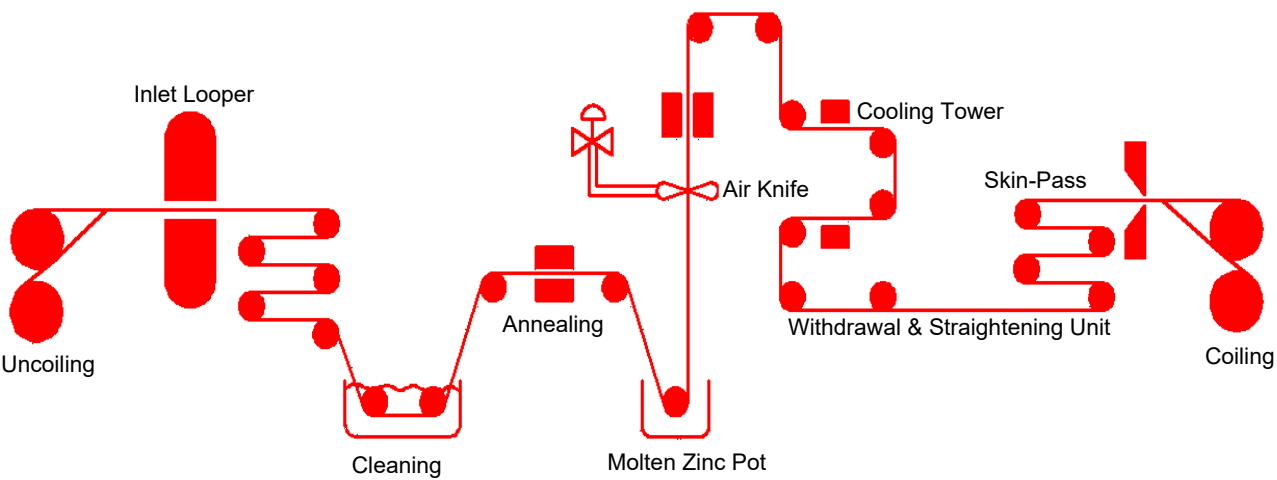

Galvanized Production Line

Process Flow of Hot-dipped Galvanized Steel Coil

Uncoiling→Cutting→Stitching/Welding→Inlet Looper→Caustic Solution/Alkali Degreasing→Cleaning→Acid Bath(Hydrochloric Or Sulfuric)→Flux Bath→

Annealing(Sealed: Pre-heating Furnace→Reduction Furnace→Cooling Furnace)→Molten Zinc Pot→Air Knife→Surface Spangle-Making→Cooling Tower→

Water Quenching Cooling→Withdrawal & Straightening Unit→Skin-Pass Machine→Chromate Treatment→Curing Furnace→Outlet Looper→Electrostatic

Oiler→Cutting→Coiling

1. Pre-Inspection – Where the cold rolled steel strip is viewed to ensure it has overall performance necessary to yield a quality galvanized coating.

2. Cleaning – Steel is immersed in a caustic solution to remove organic material such as grease and dirt, followed by dipping in an acid bath (hydrochloric or sulfuric) to remove mill scale and rust, and finally lowered into a bath of flux that promotes zinc & steel reaction and retards further oxidation of the steel sheet(steel sheetwill not react with zinc unless it is perfectly clean).

3. Galvanizing – The clean steel is lowered into a kettle containing 850 F molten zinc where the steel and zinc metallurgically react to form three zinc-iron intermetallic layers and one pure zinc layer.

4. Final Inspection – The newly galvanized steel coil is sight-inspected, followed up by measurement of coating thickness with a magnetic thickness gauge.