The Common Knowledge Galvanized Coil

The galvanized coil is a kind of steel coil that has been coated with zinc on both sides. It is widely used in various industries because of its advantages of strength, durability, toughness and corrosion resistance.

Galvanized coating Type

Galvanized coil can be produced by two main processes: continuous hot dip galvanizing and electro galvanizing. The former involves passing the steel through a molten zinc bath, and the latter involves applying zinc through electrolytic treatment.

Hot Dipped Galvanized coil a thin steel plate that is immersed in a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank containing molten zinc to make galvanized steel plate;

Cold galvanizing is also called electro-galvanizing. It uses electrolysis equipment to degrease, pickle, and then put the pipe fittings into a solution composed of zinc salts, and connects the negative electrode of the electrolysis equipment. A zinc plate is placed opposite the pipe fittings and connected to the electrolytic When the positive pole of the equipment is connected to the power supply, a layer of zinc will be deposited on the pipe fittings by using the directional movement of the current from the positive pole to the negative pole. Cold-plated pipe fittings are processed first and then galvanized.

What are the two types of hot-dip galvanizing according to different annealing methods?

Hot dip galvanizing can be divided into two types according to the annealing method: in-line annealing and out-of-line annealing.

In-line annealing means that the cold rolling or hot rolling workshop directly provides coils as the original plates for hot-dip galvanizing, and gas-protected recrystallization annealing is performed in the hot-dip galvanizing line.

That is, before the hot-rolled or cold-rolled steel plate enters the hot-dip galvanizing line, it is first recrystallized and annealed in a bottom-type annealing furnace or a bell-type annealing furnace. In this way, there is no annealing process in the galvanizing line. Before hot-dip galvanizing, the steel plate must maintain a clean pure iron active surface free of oxides and other contaminants. This method is to first remove the annealed surface iron scale by pickling, and then apply a layer of zinc chloride or a solvent composed of ammonium chloride and zinc chloride for protection to prevent the steel plate from being oxidized again.

What are the types of galvanizing annealing furnaces?

There are three types: vertical annealing furnace, horizontal annealing furnace and vertical and horizontal annealing furnace.

What are the commonly used steel types for hot-dip galvanized sheets?

Product categories: General commodity coil (CQ), structural galvanized sheet (HSLA), deep-drawn hot-dip galvanized sheet (DDQ), bake-hardened hot-dip galvanized sheet (BH), dual-phase steel (DP), TRIP steel (phase transformation induced plasticity steel), etc.

How to calculate meters produced per ton?

The specifications of the galvanized coil are 0.3×1000mm and the coil weight is 4 tons. What is the length of the galvanized coil? (The density of galvanized sheet is 7.85tons/m3)

Solution: Run Meters=1000/(density×thickness×width)X Weight of Coil=1000/(785×1.000×0.3)x 4=1698.513 Meters

What is the maximum length of time that finished products are allowed to be stored in the warehouse? Why?

Allow storage for three months to avoid oxidation caused by prolonged storage.

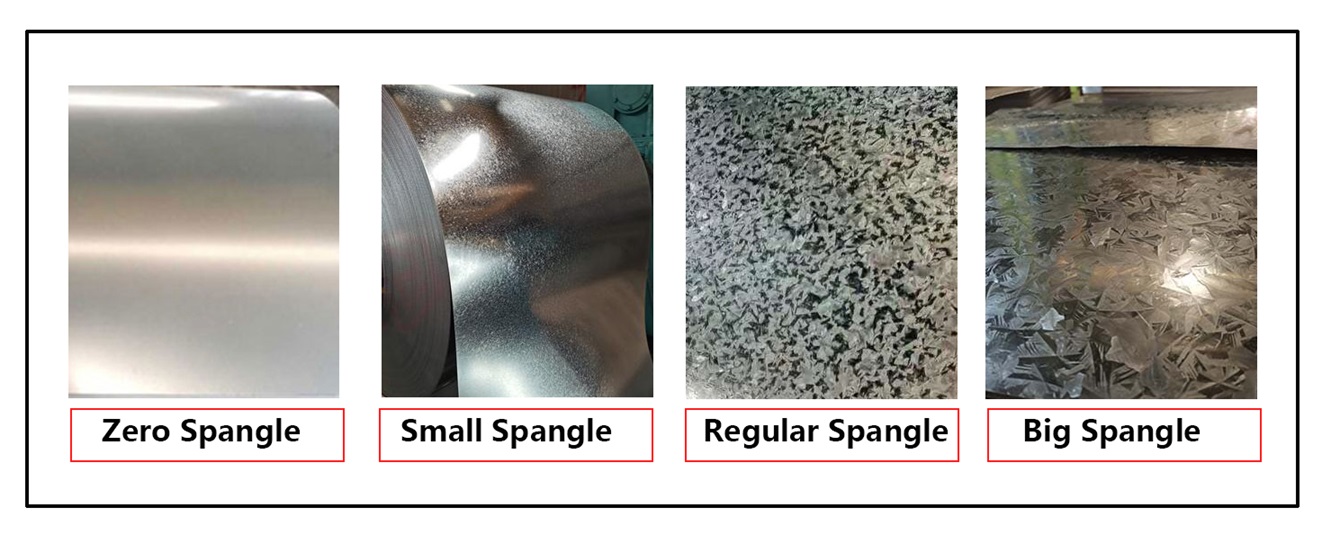

Galvanized Coil Spangle Type

(1) Regular spangle coating

During the normal solidification process of the zinc layer, the zinc grains grow freely to form a coating with obvious zinc flower morphology.

(2) Small spangle coating

During the solidification process of the zinc layer, the zinc grains are artificially restricted to form the tiniest possible zinc flower coating.

(3)Zero spangle coating

By adjusting the chemical composition of the plating solution, a coating with a uniform surface without visible spangles is obtained.

What are the methods to test the corrosion resistance of hot-dip galvanized sheets?

There are three methods to test the corrosion resistance of hot-dip galvanized sheets: salt spray test; moisture test; corrosion test.

How to calculate coating thickness?

The coating thickness formula is: CT = ZW/ZD/2

CT- Zinc coating thickness (μm),

ZW – coating weight per square meter gram

ZD – Density of zinc 7.14

100g galvanized coating thickness calculate like below:

100/7.14/2=7μm (One side)

What are the causes of white rust and black spots?

Black spots are formed by further oxidation of white rust. The main causes of white rust are:

Poor passivation, the thickness of the passivation film is insufficient or uneven; the surface is not oiled or there is residual moisture on the surface of the strip; the surface of the strip contains moisture during coiling; the passivation is not completely dried; it is damp or wet by rain during transportation or storage; The finished product is stored for too long; the galvanized sheet is in contact with or stored together with other corrosive media such as acids and alkalis.

Application and trends

Recently, the global market for galvanized coil has witnessed some significant developments. According to a report by Market Watch, the global pre painted galvanized steel coil market is expected to grow at a compound annual growth rate of 6.8% from 2023 to 2030, reaching a value of USD 33.7 billion by 2030. The report attributes this growth to the increasing demand for pre painted galvanized steel coil in various sectors such as construction, automotive, appliances and industrial machinery.

Another report by Market Watch states that the global hot-dip galvanized steel coil market size is projected to reach USD 86.9 billion by 2031, registering a CAGR of 5.2% from 2023 to 2031. The report cites the factors such as rising urbanization, industrialization, infrastructure development and environmental awareness as the drivers for the growth of this market segment.

These reports indicate that galvanized coil is a promising product that has a huge potential in the future. Galvanized coil manufacturers and suppliers should seize this opportunity and provide high-quality products and services to their customers.