Introduction

Galvanized steel is among the most popular steel types because of its extended durability, having the strength and formability of steel plus the corrosion protection of the zinc-iron coating. This versatility makes it applicable to a variety of projects and industries, including agriculture, solar, automotive, construction, and so on.

Whether you are looking for hot dip galvanized steel, galvanised steel mesh panels, galvanised mild steel, galvanized mild steel, or galvanized ribbed sheet metal, understanding their benefits and applications can help you make informed decisions.

In this blog, we will explore the importance of galvanized steel, its manufacturing process, applications, and why it is a preferred choice in various industries.

Understanding Galvanized Steel

Galvanized steel is essentially steel that has been coated with a layer of zinc to prevent corrosion and rusting. The zinc coating acts as a protective barrier against moisture and environmental elements, increasing the steel’s lifespan. This type of steel is used extensively in construction, infrastructure, fencing, and manufacturing due to its excellent resistance to oxidation.

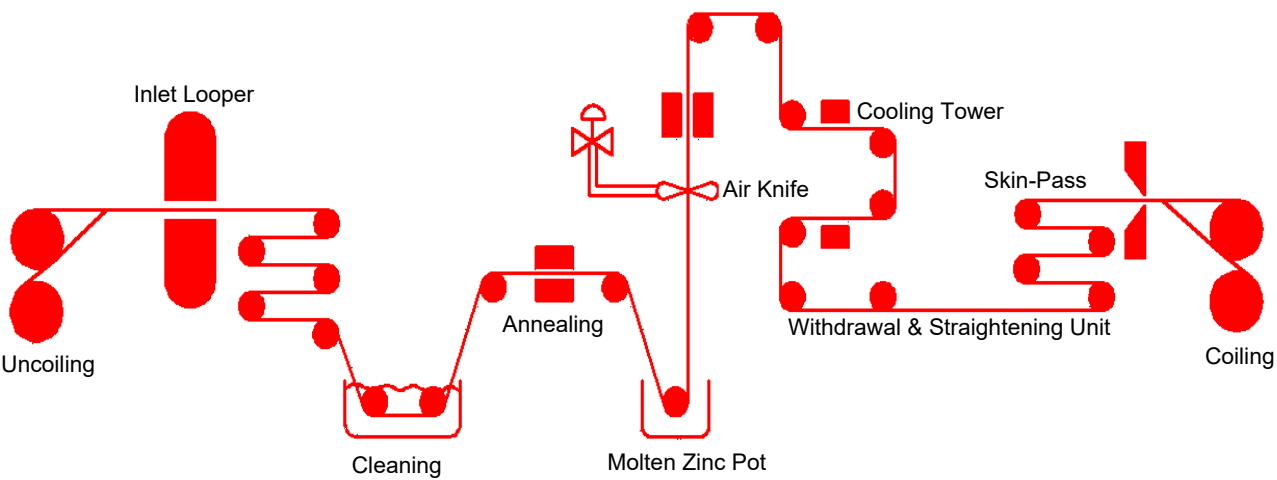

The Hot-Dip Galvanizing Process

- Cleaning: The steel is cleaned using a chemical process to remove dirt, grease, and scale.

- Pickling: The steel is then treated with acid to remove oxides and mill scale.

- Fluxing: A flux solution is applied to prevent oxidation before immersion in molten zinc.

- Galvanizing: The steel is dipped into a molten zinc bath at around 450°C (842°F), where the zinc forms a metallurgical bond with the steel surface.

- Cooling and Inspection: The steel is cooled in water or air and inspected for uniform coating.

Fig: Method of the Hot -Dip Galvanization process (taken from internet)

This process provides a robust zinc coating that protects the steel from environmental factors, making it suitable for harsh conditions.

How long does hot dip galvanizing take?

Provided reasonable notice is given, most articles can be hot dip galvanized and returned to the fabricator within a week. A typical turnaround, depending on size of the order, is three days. Galvanized steel bolts and nuts are now widely stocked but it is advisable that orders for galvanized fasteners should be placed as early as possible.

Size of Galvanized Article

The hot dip galvanising process is very versatile and articles ranging in size from nuts and bolts to long structural sections can be treated. This range, together with the ability to bolt or weld fabrications after galvanizing, allows almost any size of structure to be galvanized.

Applications of Galvanized Steel Products

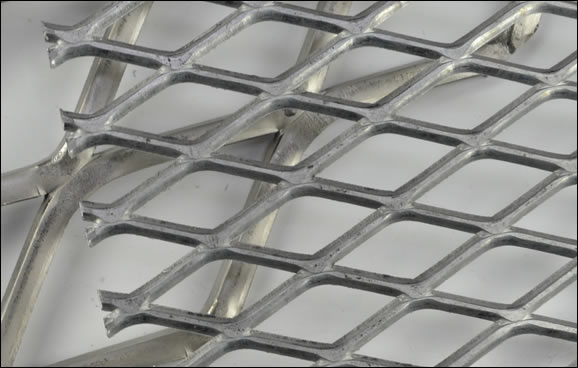

1. Galvanised Steel Mesh Panels

Galvanised steel mesh panels are widely used for fencing, security enclosures, and construction reinforcement. These panels are manufactured using welded or woven steel wires that are then hot-dip galvanized for rust protection. They are ideal for:

- Security fencing for commercial and industrial properties

- Animal enclosures and agricultural applications

- Concrete reinforcement in construction projects

- Window and door grilles for added security

The durability of galvanized steel mesh panels makes them suitable for both indoor and outdoor applications, as they can withstand extreme weather conditions without corroding.

2. Galvanised Mild Steel

Both galvanised mild steel and galvanized mild steel refer to mild steel that has been coated with zinc through the galvanization process. Mild steel is known for its flexibility and ease of fabrication, and galvanization enhances its longevity. Common uses include:

- Structural components in buildings and bridges

- Automotive body parts and frames

- Storage tanks and pipelines

- Railway tracks and transmission towers

Due to its malleability and strength, galvanised mild steel is commonly used in applications requiring welding and shaping without compromising corrosion resistance.

3. Galvanized Ribbed Sheet Metal

Galvanized ribbed sheet metal is another essential material used in roofing, cladding, and structural reinforcements. The ribbed design provides additional strength, making it ideal for high-load applications. Some key applications include:

- Roofing sheets for industrial and residential buildings

- Cladding for walls and ceilings

- Decking for mezzanine floors and bridges

- Agricultural storage sheds and barns

This type of sheet metal offers a combination of strength, lightweight properties, and excellent resistance to environmental damage.

Advantages of Using Galvanized Steel

1. Corrosion Resistance

The zinc coating on galvanized steel prevents rust and corrosion, extending the lifespan of the material even in harsh environments, including coastal and industrial areas.

2. Cost-Effective Solution

Compared to stainless steel or aluminum, galvanized steel is more affordable while still providing excellent durability. The reduced maintenance costs make it a preferred choice for long-term investments.

3. Low Maintenance Requirements

Galvanized steel requires minimal upkeep, making it ideal for structures that need to withstand outdoor exposure without frequent repairs or replacements.

4. Eco-Friendly and Sustainable

Galvanized steel is 100% recyclable, contributing to sustainable construction practices. The longevity of galvanized steel also reduces material wastage and environmental impact.

5. High Durability and Strength

The metallurgical bond between zinc and steel provides superior protection against mechanical damage, making it ideal for heavy-duty applications.

Choosing the Right Galvanized Steel for Your Needs

When selecting galvanized steel products, consider the following factors:

- Application Requirements: Determine whether you need mesh panels, mild steel, or ribbed sheet metal based on your project’s structural and durability needs.

- Thickness of Zinc Coating: A thicker zinc layer offers better protection but may increase costs.

- Environmental Conditions: For highly corrosive environments, opt for heavy-duty hot-dip galvanized steel.

- Fabrication Needs: If welding or shaping is required, galvanized mild steel is a good choice due to its malleability.

Conclusion

Galvanized steel, whether in the form of hot dip galvanized steel, galvanised steel mesh panels, galvanized mild steel, or galvanized ribbed sheet metal, is a must material in modern construction and manufacturing. Its corrosion resistance, durability, and cost-effectiveness make it an ideal pick for a wide range of applications. Investing in galvanized steel ensures long-term performance, reduced maintenance costs, and enhanced structural integrity.

Whether you’re working on a large industrial project or a small DIY home improvement, choosing the right type of galvanized steel can significantly improve the longevity and resilience of your structures.

If you’re in need of high-quality galvanized steel products, please consult one of the reputable manufacturers and suppliers Qingdao Witop Steel group to find the best materials suited to your specific requirements. Qingdao Witop Steel group is to create value with our customers, improving competitiveness and productivity together. Through a highly efficient technological and industrial base in China and a global commercial network, we are committed to establishing a long-term cooperation with the customer.