Basic introduction

Galvalume steel is a popular material used across various industries for its durability, corrosion resistance, and versatility. Whether it’s for roofing, siding, or structural applications, Galvalume steel offers exceptional performance.

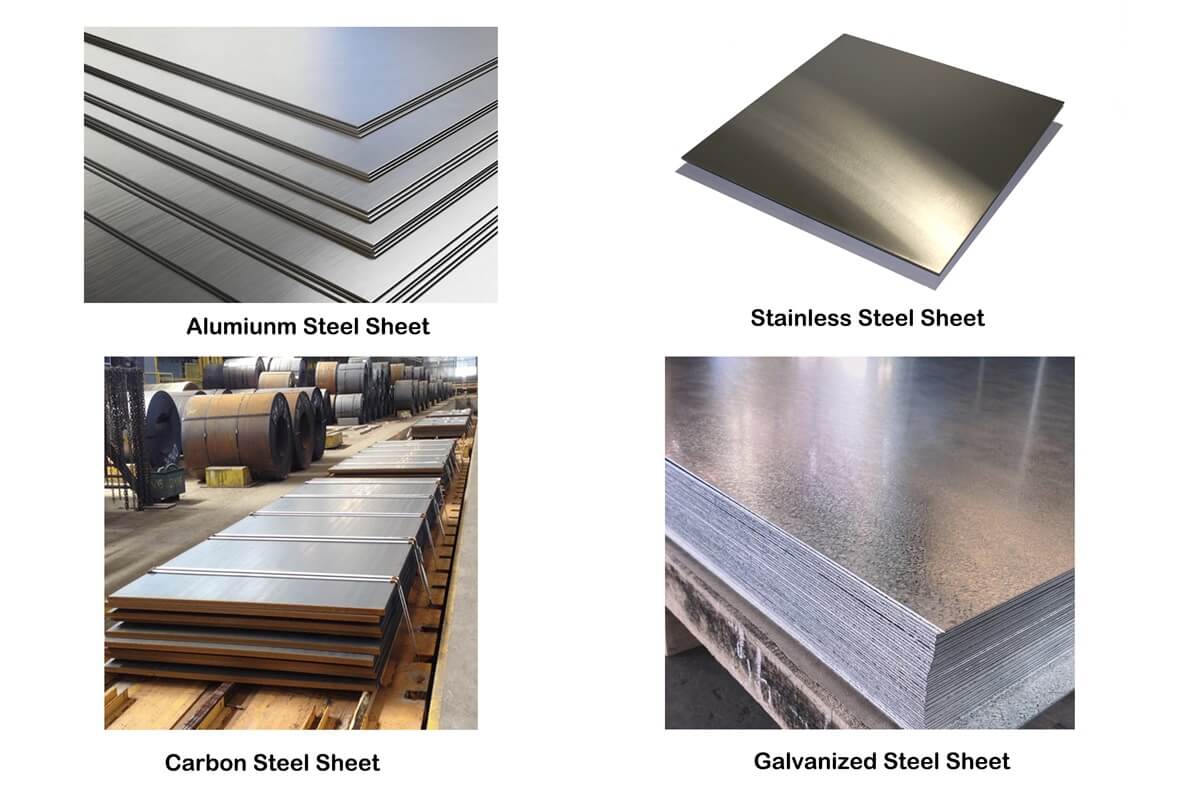

Simply put, Galvalume is cold-rolled steel that is hot-dipped in aluminum and zinc alloys. In this blog post, we’ll dive deep into Galvalume steel coil, sheet, and metal products, covering their features, benefits, applications, and pricing factors. We’ll also explore popular variations like bare Galvalume sheet and Galvalume AZ150, as well as provide insights into choosing the right Galvalume material for your project.

Galvalume Steel: A quick history of it’s existence

Bethlehem Steel introduced the Galvalume coating to the construction industry in the early 1970s. Before Galvalume came into existence, most metal roofing was galvanized steel. However, because of the superior durability and corrosion resistance of Galvalume, 90+ percent of the metal roofing industry transitioned from galvanized substrates to a Galvalume substrate in the mid to late 1990s.

Galvalume combines three of the most high-performing and important metals used in roofing today — steel, aluminum, and zinc. Manufacturers begin with a cold-rolled carbon steel base sheet that is continuously hot-dipped with aluminum and zinc alloys (AZ) until it reaches a coating of 55% aluminum, 43.4% zinc, and 1.6% silicone.

This process allows for one material to have some of the best characteristics of each metal, which makes Galvalume unique.

Types of Galvalume Products: Let’s deep dive into the arena of products

1. Galvalume Steel Coil

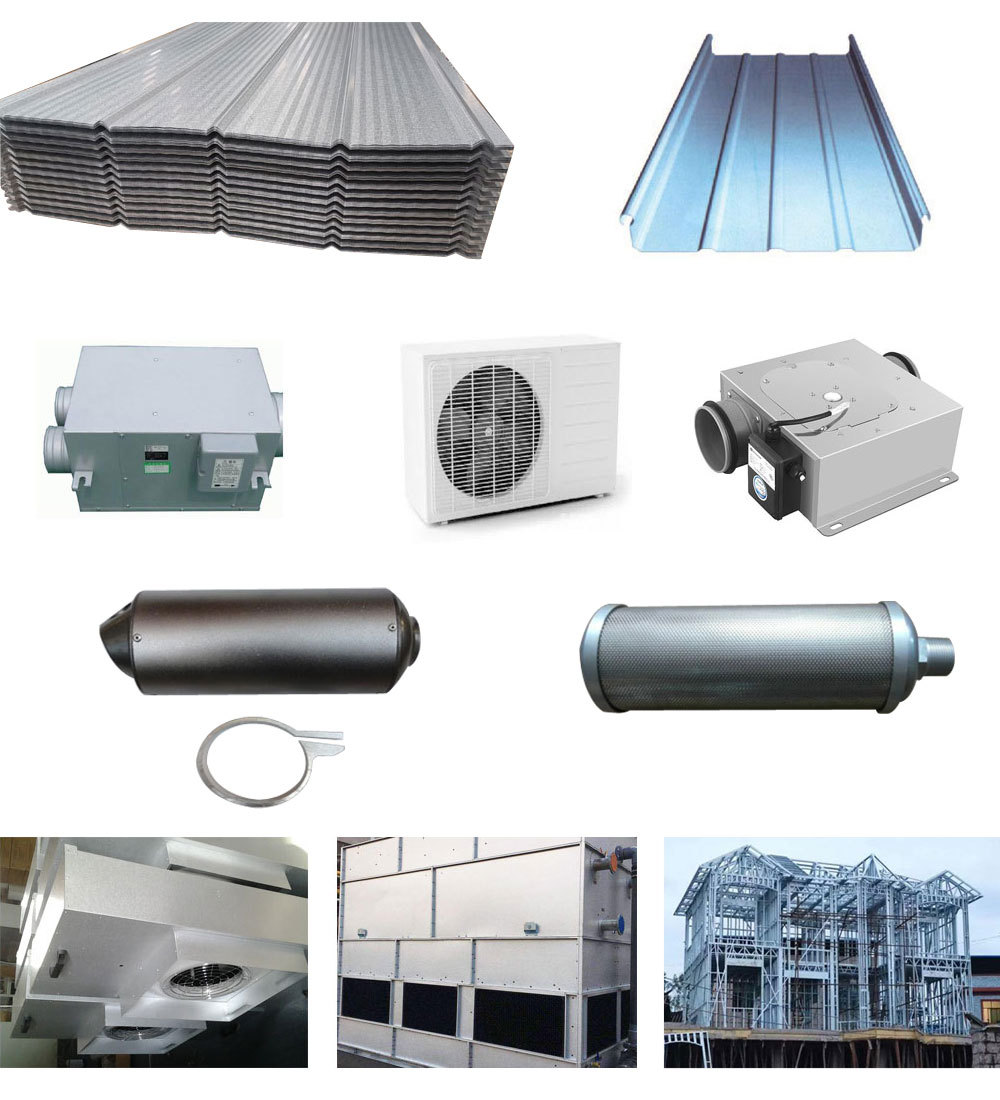

Galvalume steel coil is a continuous roll of Galvalume-coated steel that is used as the base material for producing a wide range of products, including panels, sheets, and structural components. Galvalume coils are popular for manufacturing applications that require large volumes of metal, as they can be easily processed into various sizes and shapes.

2. Galvalume Steel Sheet

Galvalume steel sheet refers to flat sheets of metal that have been coated with the Galvalume alloy. These sheets are available in various gauges (thicknesses) and are widely used in construction, especially for roofing and siding.

Galvalume sheets offer a sleek, aesthetically pleasing appearance, which can be a key factor in their popularity for architectural designs.

3. Bare Galvalume Sheet

Bare Galvalume sheets are simply Galvalume steel sheets without any additional coatings or paint applied to them. While the Galvalume coating provides corrosion resistance, some projects may require an additional finish, such as paint or a protective film, depending on the specific needs of the application.

4. Galvalume Panels

Galvalume panels are pre-formed sheets of Galvalume steel that have been shaped into panels for easy installation. These panels are widely used for roofing and wall applications in both commercial and residential projects. Galvalume panels are highly valued for their weather-resistant properties and long-lasting durability.

5. Standing Seam Galvalume

Standing seam Galvalume is a type of metal roofing system where the metal panels are joined together by raised seams, which are then locked into place. This system provides a durable, weather-resistant roofing solution and is usually used in commercial buildings, industrial facilities, and modern residential homes. The raised seams prevent water infiltration and provide a sleek, contemporary look.

Benefits of Using Galvalume Steel

Galvalume steel is an excellent choice for various applications due to its combination of strength, durability, and corrosion resistance. Here are some of the key benefits of using Galvalume steel:

- Superior Corrosion Resistance

- Long Lifespan

- Energy Efficiency

- Aesthetic Appeal

- Lightweight Yet Strong

- Cost-Effective

Popular Variants of Galvalume Steel

1. Galvalume AZ150

One of the most common variants of Galvalume steel is AZ150. The “AZ” refers to the aluminum-zinc alloy coating, and the “150” indicates the coating weight in grams per square meter. Galvalume AZ150 has a high level of corrosion resistance and is suitable for a variety of exterior applications, including roofing, siding, and cladding.

2. 26 GA Galvalume

The term “26 GA” refers to the gauge of the Galvalume steel sheet. In the case of 26 GA Galvalume, this is a commonly used thickness for roofing and siding applications. It strikes a good balance between durability and flexibility, making it suitable for both residential and commercial construction.

3. Hollow Galvalume

Hollow Galvalume refers to Galvalume-coated steel that has been formed into hollow sections, such as tubes or pipes. These hollow sections are used in structural applications, including framing and supports. The Galvalume coating provides added corrosion resistance, which is important for materials exposed to the elements.

Applications of Galvalume Steel

1. Roofing

Galvalume steel is widely used for roofing materials because of its ability to withstand extreme weather conditions, including rain, snow, hail, and UV exposure. Standing seam Galvalume roofs, in particular, are known for their long lifespan and low maintenance requirements.

2. Siding

Galvalume is also a popular choice for metal siding on buildings. It is durable, weather-resistant, and offers a sleek, modern aesthetic. Galvalume siding can be used in both residential and commercial applications, offering long-lasting protection from the elements.

3. Gutters and Downspouts

Due to its corrosion resistance, Galvalume is often used to manufacture gutters, downspouts, and other rainwater management systems. These components are exposed to constant moisture and need to be highly durable to avoid rust and deterioration.

4. Automotive and Appliances

Galvalume-coated steel is used in the manufacturing of appliances such as refrigerators, washing machines, and air conditioning units. The steel’s resistance to rust and its aesthetic appeal make it a popular choice for the appliance industry.

5. Agricultural Buildings

Farm buildings, barns, and other agricultural structures benefit from the durability and corrosion resistance of Galvalume. These buildings are often exposed to harsh weather and environmental conditions, making Galvalume a preferred material.

Factors contributing Galvalume Steel Pricing

- Coating Thickness: Products like Galvalume AZ150 are typically more expensive than lower coating grades due to the enhanced corrosion resistance.

- Gauge: Thicker gauges generally cost more because they offer better durability and load-bearing capacity.

- Market Conditions: Prices can fluctuate depending on global steel prices, shipping costs, and demand for metal products.

- Customization: Pre-painted or specially processed Galvalume products may cost more due to additional manufacturing steps.

Conclusion

Galvalume steel is an incredibly versatile, durable, and cost-effective material that has earned its place in various industries. From Galvalume steel coils and sheets to specialized panels and standing seam roofing, this material provides excellent resistance to corrosion, making it a top choice for both residential and commercial projects.

Whether you’re building a new home, renovating an industrial facility, or designing an agricultural building, Galvalume offers a combination of performance and aesthetic appeal that few other materials can match. By understanding the different types of Galvalume products and their pricing, you can make an informed decision that will provide long-term value and protection for your project.

Witop steel have one Galvalume steel production line with annual capacity of 80,000 tons, which can produce JIS G 3321, EN 10215 and ASTM 792 standard alu-zinc steel coil, and relatively SGLCC/SGLCH, DX51D/DX52D/DX53D, G250/G550 material grade.

We are exporting Galvalume steel products to more than 150 countries world-wide.