EN 10169

Table of Contents

What is EN 10169?

EN 10169 of this European Standard gives the specific requirements for continuously organic coated (coil coated)steel flat products used for building interior applications.

It particularly specifies the performance requirements of different product flexibility categories and different corrosion protection categories.

General information concerning continuously organic coated steel flat products

Products for building exterior applications are covered

The products covered are wide strips, sheets cut from wide strip, slit wide strips, strips rolled in widths less than600 mm and cut lengths (from sheet or strip).

PPGI color coated steel coil have painting film to cover its surface and protect the steel from rusting, in addition to zinc coating film protection. The service life of prepainted steel coil is about 2 times longer than that of the galvanized steel coil.

EN 10169 Equivalent

Chinese standard: GBT 12754

American standard: ASTM A755M

Japanese standard: JIS G3312

Information to be supplied by the purchaser

The following information is required from the purchaser so that the manufacturer may supply the products toconform with the requirements:

A. product type (strip, sheet or cut length);

B. complete designation of the substrate EN 10147 and EN 10215;

C. complete designation of the coating material, coating system and coating thickness, product, flexibility category and corrosion protection (interior) category of the top side and when applicable of the reverse side Coating thickness, Coating Material and Coil Coating Systems;

D. where appropriate, details of the required decorative properties and subsequent surface treatment (any required decorative properties

(colour, gloss, embossing) and Temporary protection treatment or strippable film);

E. other requirements on the characteristics of the products ; nominal dimensions of the product substrate;

G. quantity;

H. internal and maximum external diameter and mass limit for coils, or limit dimensions and mass limit for bundlesof sheets; any testing required at the manufacturer’s works, type of test and type of inspection document (Inspection and testing);

J. any requirement concerning marking;

K. requirements on packing and dispatch.

Steel substrates of EN 10169

The initial product for continuously organic coated steel flat products according to this standard shall be steel strip with or without metallic coating complying with one of the following standards: EN 10130, EN 10139, EN 10142, EN 10147, EN 10152, EN 10154, EN 10214, EN 10215, EN 10268, EN 10292.

If agreed at the time of inquiry and order the products may be supplied with other steel substrates.

When applicable nominal metal coating masses shall be indicated on ordering.

Coating materials of EN 10169

The more common coating materials used on the exposed sides of organic coated flat products suitable for building interior applications, together with their coating thickness (dry film thickness) are given in annex B.

Coil coating systems EN10169

The choice of the coating for each side of the product shall be agreed between the purchaser and the supplier to meet the purchaser’s requirements of the product flexibility category and the corrosion protection (interior categories of the sides).

When the coatings of the two sides are different, the outside of the coil (in the case of strip supplied in coil form) is normally the top side; for sheets and cut lengths (in stacks or bundles), this side is normally uppermost.

if the purchaser requires an alternative arrangement, this shall be expressly stated at the time of inquiry and order.

Temporary protection treatment (strippable film)

The temporary protection treatment (e.g. type, thickness) shall be selected upon agreement at the time of enquiry and order.

Coil coated products can be supplied with the additional temporary protection of a strippable film. This protection isparticularly recommended when special requirements during transportaion, storage or processing are expected.The kind of strippable film (e.g. type, thickness) shall be agreed at the time of enquiry and order.

Gloss Class of EN 10169

The specular gloss shall be measured in accordance with the specified standards. When required, the tolerances shall be as given in the table below.

| Tolerances on specular gloss values in gloss units using a 60° head | ||

| Gloss Rate | Gloss Class | Tolerance |

| Under 10 | Matt | 3 |

| 10 to 20 | Low Gloss | 4 |

| 20 to 40 | Satin | 6 |

| 40 to 60 | Semi-gloss | 8 |

| 60 to 80 | Gloss | 10 |

| Over 80 | High Gloss | Minimum 80 |

EN 10169 Mechanical properties

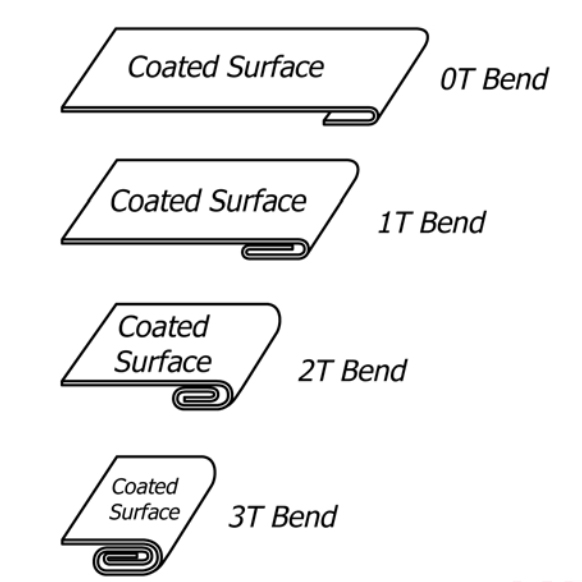

Bent Test of EN 10169

The bend test shall be as follows:

- The test piece should have a width between 75 mm and 125 mm, with a length appropriate for the test. Unless otherwise specified, one test piece should be cut from each test specimen parallel to the rolling direction of the base metal.

- Referring to the internal spacing of the bend shown below, the test piece should be manually bent using a vise or similar device at a right angle to the longitudinal direction of the piece, as illustrated in the pictures below. If a hand vise is not available, other suitable testing methods may be used.

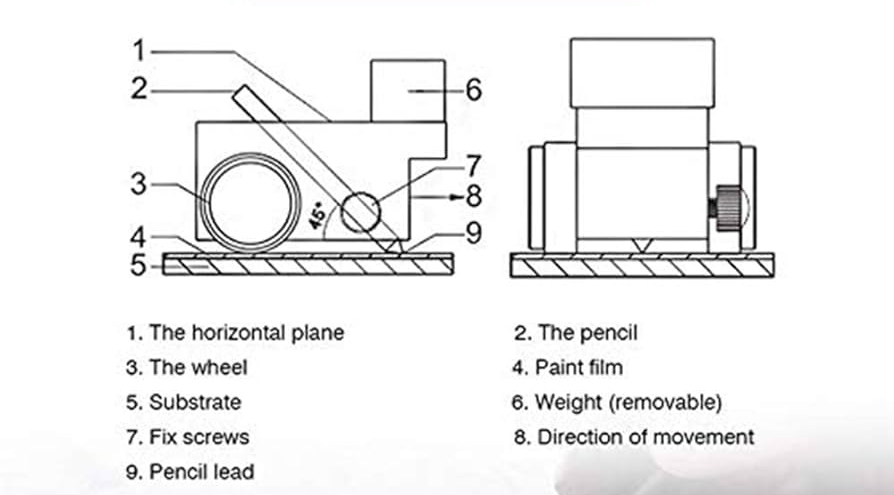

Pencil hardness test of EN 10169

Holding the prepared pencil at an angle of approximately 45 degrees to the surface of the test specimen, draw straight lines as shown in the pictures below. Apply a load of about 10 N while drawing the lines. Each line should be at least 20 mm in length, and there should be no fewer than three lines drawn.

For additional testing methods, please refer to the production standards outlined in JIS G3312.

WitopSteel can help you find the best Galvanized Steel Coil manufacturers in China. If you need a Prepainted steel coil supplier, you can contact us. I will provide a quote based on assured quality goods.