EN 10147

Table of Contents

What is EN 10147?

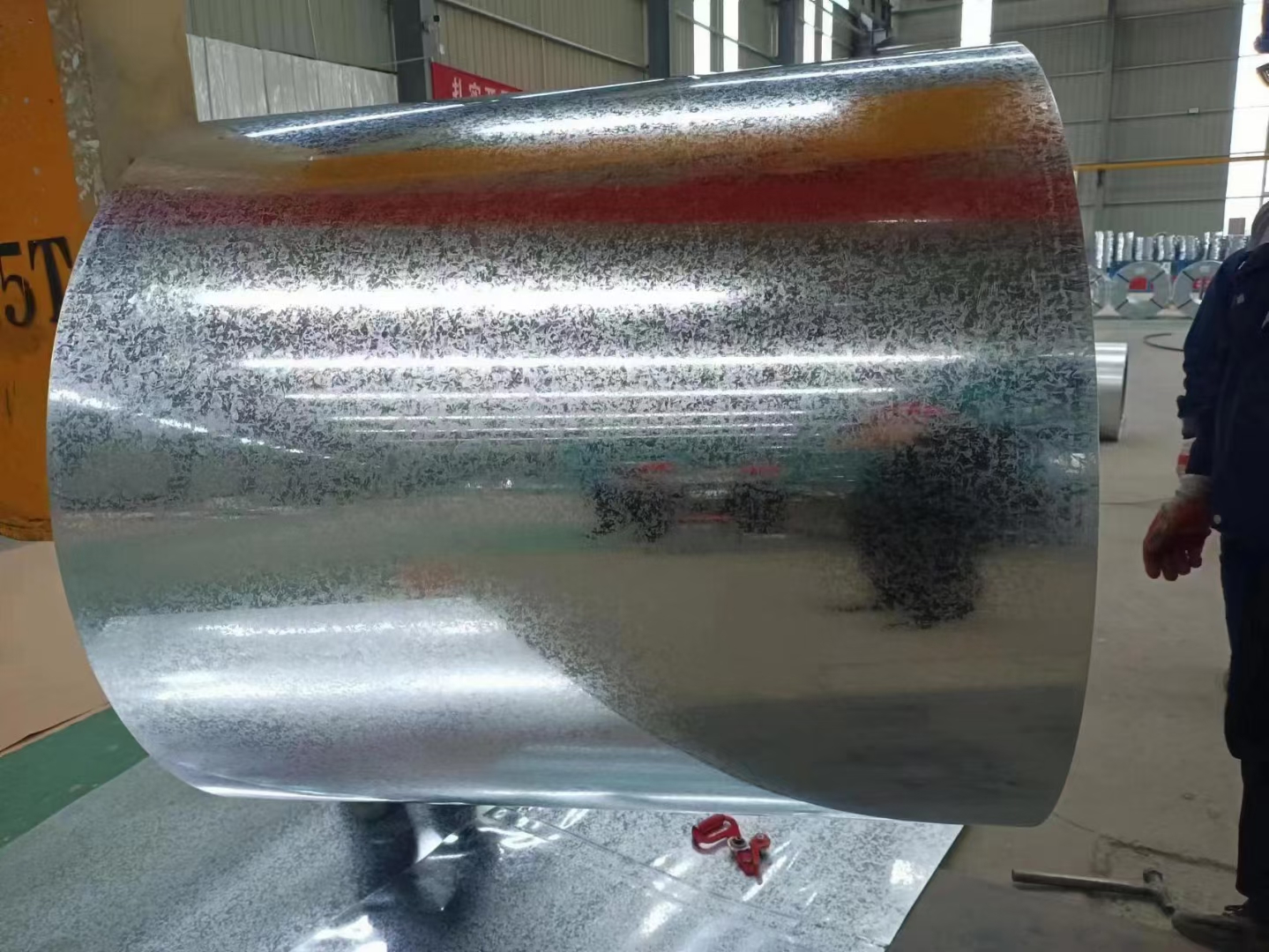

EN 10147 European Standard specifies requirements for continuously hot-dip zinc-coated flat products. The thickness is the final thickness of the delivered product after zinc coating. This European Standard applies to strips of all widths and to sheets cut from it (> 600 mm width) and cut lengths (< 600 mm width). EN 10147 specification covers steel sheets, zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) by the hot-dip process in coils and cut lengths.

EN 10147 Equivalent

Chinese standard: GBT 2518-2008 American standard: ASTM A653M Japanese standard: JIS G3302EN 10147 Steel grade and Mechanical properties

Steel grade and Mechanical properties| Grade | Yield strength | Tensile strength | Elongation |

| Steel Grade | N/mm2 | % | |

| S220GD | 220 Min | 300 Min | 20Min |

| S250GD | 250 Min | 330 Min | 19 Min |

| S280GD | 280 Min | 360 Min | 18 Min |

| S320GD | 320 Min | 390 Min | 17 Min |

| S350GD | 350 Min | 420 Min | 16 Min |

| S550GD | 550 Min | 560 Min | – |

| NOTE: 1 N/mm2 = 1 MPa |

Coating Mass

The coating mass shall correspond to the data in the Table as below. The values apply for the total mass of the coating on both surfaces for the triple spot test and the single spot test. The coating mass is not always equally distributed on both the product surfaces. However, it maybe assumed that a coating mass of at least 40 % of the value given in the Table for the single spot test exists on each surface of the product.Coating Mass

| Coating Designation | Minimum coating mass in g/M2 including both surface | |

| Triple Spot Test | Single Spot Test | |

| 100 | 100 | 85 |

| 140 | 140 | 120 |

| 200 | 200 | 170 |

| 225 | 225 | 195 |

| 275 | 275 | 235 |

| 350 | 350 | 300 |

| 450 | 450 | 385 |

| 600 | 600 | 510 |

| The coating mass of 100 g/M2 (including both surface) corresponds to a coating thickness of 7.1 um per surafce | ||