Foreword

Development of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in the East African Community. It is envisaged that through harmonized standardization, trade barriers that are encountered when goods and services are exchanged within the Community will be removed.

The Community has established an East African Standards Committee (EASC) mandated to develop and issue East African Standards (EAS). The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the public and private sector organizations in the community.

East African Standards are developed through Technical Committees that are representative of key stakeholders including government, academia, consumer groups, private sector and other interested parties.

Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the Principles and procedures for development of East African Standards.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

The committee responsible for this document is Technical Committee EASC/TC 35, Steel and steel products.

This third edition cancels and replaces the second edition (EAS 11: 2008), which has been technically revised.

Hot-dip galvanized plain and corrugated steel sheets — Specification

1. Scope

This East African Standard specifies requirements, test methods and sampling for hot-dip galvanized plain and corrugated steel sheets for roofing and general use.

This standard does not cover all the special purpose profiles.

2. Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EAS 196, High strength low — alloy carbon steel for hot rolled and cold rolled sheet — Specification

ISO 6507-1, Metallic materials — Vickers hardness test — Part 1: Test method

ISO 6508-1, Metallic materials — Rockwell hardness test — Part 1: Test method

ISO 6892-1, Metallic materials – Tensile testing — Part 1: Method of test at room temperature

3. Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1 galvanized sheets

steel sheets with a uniform coating of zinc applied by the hot-dip process

3.2 corrugated sheets

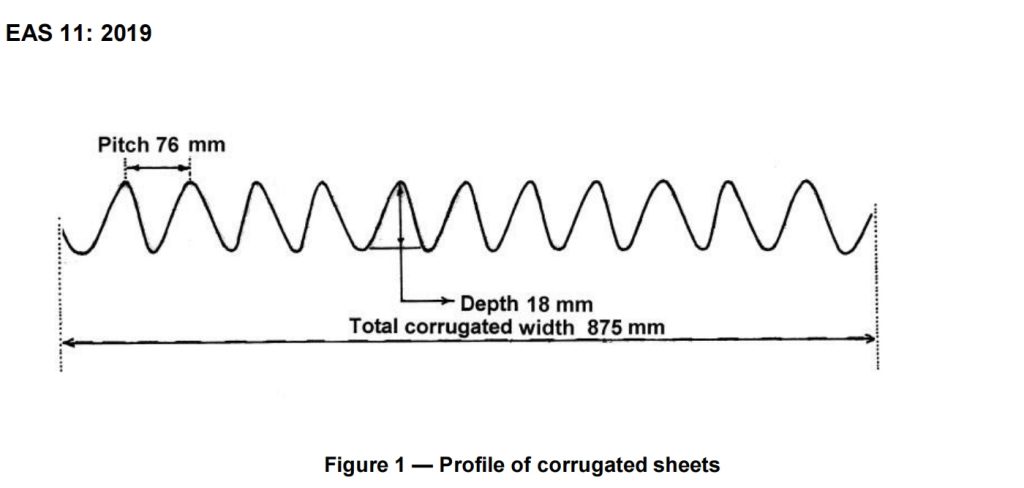

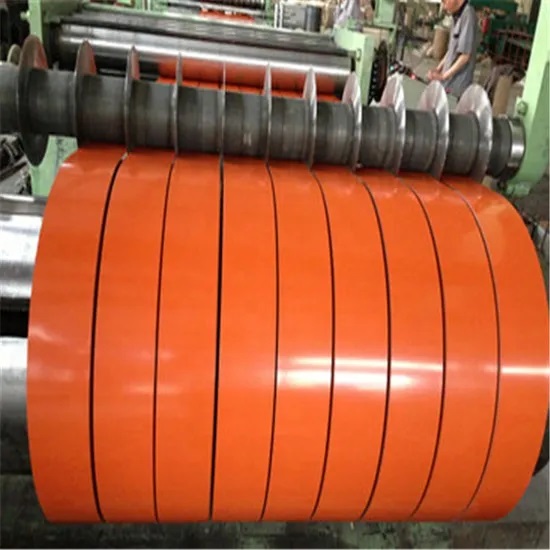

galvanized steel sheets which are mechanically formed to obtain regular, sinusoidal, profiles, as shown in Figure 1.

3.3 thickness

in reference to the base metal

3.4 plain

flat or even sheets without any relief forms

3.5 pitch

distance between two corresponding and consecutive points on the corrugated steel sheets along its width

4. General requirements

4.1 Dimensions

4.1.1 Length

When measured in accordance with 9.2.2, the nominal length of plain and corrugated sheets, shall be 2000 mm or 2500 mm or 3000 mm with a permissible deviation of + 0.5 %, 0 %.

4.1.2 Width

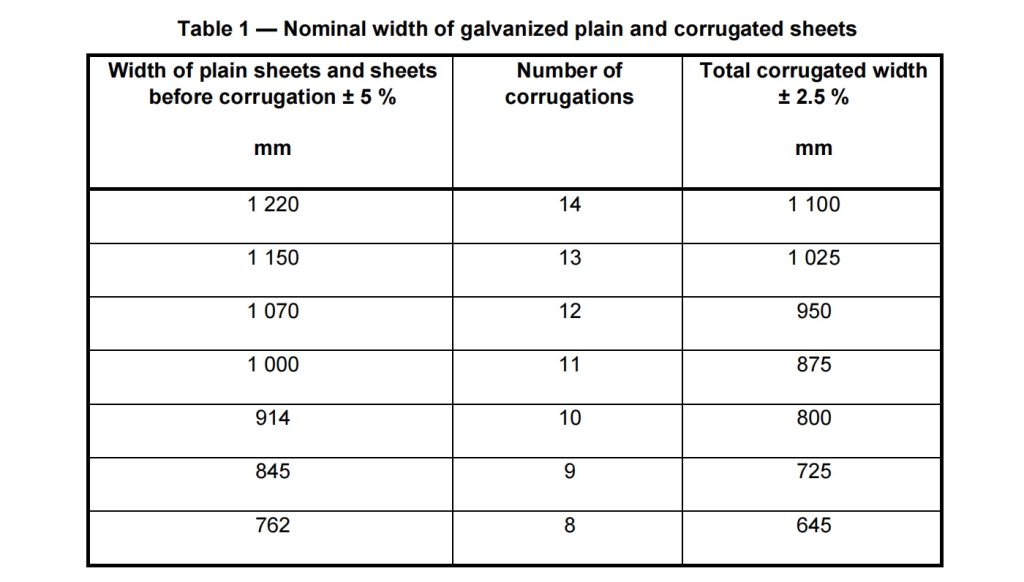

The width of galvanized plain and corrugated sheets when measured in accordance with 9.2.4 shall be as specified in Table 1.

4.1.3 Thickness

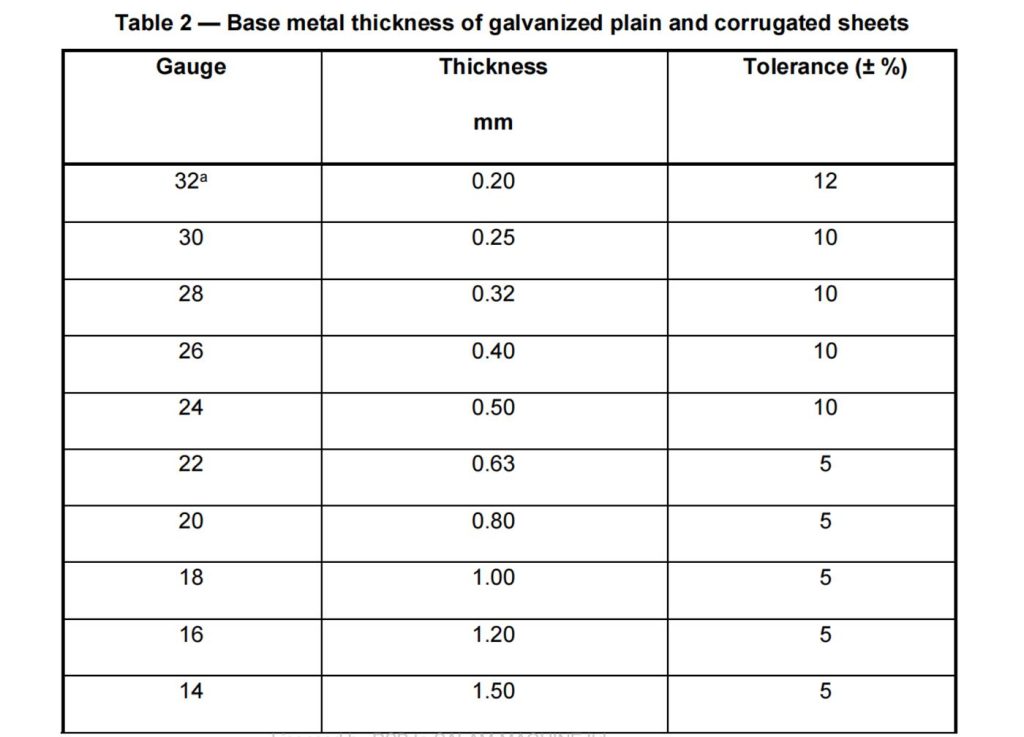

The thickness of galvanized plain and corrugated sheets shall be expressed in gauges. The corresponding thickness in millimetres shall be as specified in Table 2.

Gauge 32 sheets, shall be clearly marked “not for roofing”.

4.1.4 Squareness

When measured in accordance with 9.2.3, the distance between diagonally opposite corners of the sheet shall not differ by more than 10 mm.

4.2 Profile

4.2.1 Depth

The depth of corrugations shall be 18 mm ± 1.5 mm, when measured in accordance with 9.2.6.

4.2.2 Pitch

The pitch of the corrugations shall be 76 mm ± 2 mm when measured in accordance with 9.2.5.

4.3 Tensile strength

The tensile strength of galvanized plain and corrugated sheets when determined in accordance with 9.2.7 shall be not less than 300 N/mm2. The yield strength shall be not less than 210 N/mm2.

4.4 Hardness

The hardness properties of the steel sheets shall be as follows:

For 32G and 30G sheets to be full hard and for 28G and above sheets to be full hard or half hard.

4.5 Resistance to bending

When tested in accordance with 9.2.8, the sheet shall not crack, flatter or splinter.

4.6 Freedom from defects

The sheets shall be uniform, clean and free from defects that would adversely affect their use.

4.7 Finish

The finish on galvanized plain and corrugated sheets shall be “Mill Finish”.

5. Galvanization process (criteria of compliance)

5.1 General requirement

The steel sheets shall be manufactured in accordance with accepted current practice and shall be from rolled milled steel made by a suitable process and meeting the requirements of EAS 196. The sheets shall be true to size and homogenous. They shall also be free from holes, tears, twists, cambers and damaged edges and corners. Corrugations shall be parallel to the edges of the sheets.

5.2 Zinc coating

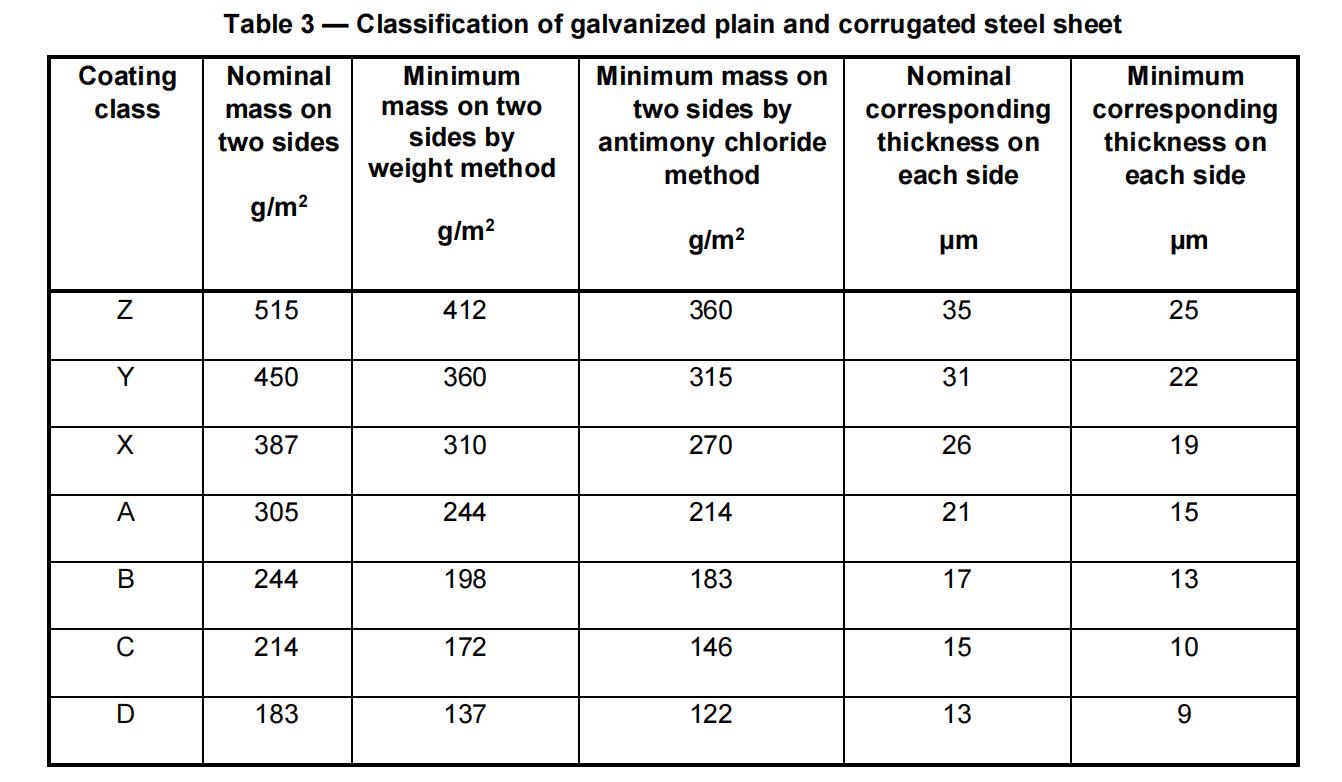

5.2.1 Zinc coating shall be carried out by the hot-dip process with smelter containing not less than 98.5% pure zinc. The minimum mass of zinc coating on the two sides of sheet and the corresponding thickness of zinc coating on each side shall comply with the classification specified in Table 3.

5.2.2 The nominal mass of zinc coating per square metre, when tested according to methods specified in 8.1, shall correspond to the classification specified in table 3. The minimum values determined by the methods specified in 8.1, shall be as shown in Table 3.

5.2.3 Zinc coating adherence shall be such that there will be no flaking or splintering in the finished galvanized plain or corrugated sheet, when tested in accordance with 8.2.

5.3 Classification of zinc coating

Galvanized plain and corrugated steel sheets shall be classified into seven (7) classes depending on the mass of zinc coating applied to meet different service and environmental conditions. The classes shall be as specified in Table 3.

6. Marking

6.1 Conforming sheets

6.1.1 Marking

Each galvanized plain or corrugated steel sheet conforming to this standard shall be legibly and indelibly marked with the following:

a) Manufacturer’s name and/or trade mark;

b) The base metal thickness expressed in millimetres and gauge with word “GAUGE” in full;

c) The coating class of sheet;

d) The batch identification; and

e) Gauge 32 sheets, shall be clearly marked “Not for roofing” in every 1 m along the length.

6.2 Non-conforming sheets

All non-conforming sheets shall be identified by cutting off all four corners at least by 75 mm along the edges diagonally and shall be marked “Rejected” with indelible ink.

7. Sampling

7.1 General

The sampling procedures in 7.2 and 7.3 shall be applied in determining whether a lot complies with the relevant requirements of the specification.

The samples taken shall be deemed to represent the lot.

7.2 Sample for inspection and dimensional test

7.2.1 From the lot, random sampling shall be done in accordance with Table 4.

7.2.2 For the manufacturing industry, three sheets shall be taken in every 8 h shift.

7.3 Sample for other tests

From the sample taken in accordance with 7.2.1, take at random one sheet.

8. Test for zinc coating

8.1 Mass of zinc coating

8.1.1 Weight method

The steel sheets are weighed before galvanizing. They shall be then passed through the galvanizing process and weighed again at the end of the process.

8.1.2 Antimony chloride method

The test piece of minimum area 5 000 mm2 shall be weighed and then introduced into a zinc-stripping solution of one part antimony chloride and twenty parts hydrochloric acid (specific gravity 1.19), and shall remain therein until the coating has completely dissolved. The test piece shall be taken out of the solution when the violent chemical reaction ceases, rinsed in running water, brushed to remove any loose substance, dried and weighed.

NOTE The Antimony Chloride Method will be used as the criteria for compliance and not the weight method.

8.1.3 Calculation

The average of the gain or loss in mass (grams) calculated from the results obtained from three test pieces shall represent the mass of zinc coating on both sides of each test piece (see Annex A).

The results shall be expressed in grams per square metre (g/m2).

8.2 Coating adherence test

The test shall consist of subjecting the test piece to deformation by bending in one direction. The test piece shall either be bent mechanically or gripped in hand-operated device (mandrels may also be used) and bent until the two legs of the test piece are parallel to each other, i.e. through 180°.

A second test piece shall be bent in the opposite direction.

The sheets shall be bent round a diameter of 38 mm.

9. Inspection and physical tests

9.1 Inspection

Inspect the sample taken in accordance with Clause 7 for compliance with 4.6 and 5.1.

9.2 Dimensions

9.2.1 Thickness

Measure with micrometre screw gauge to the nearest 0.01 mm the thickness of each sheet in the sample of the sheets at any point at least 10 mm from an edge and end of the sheet.

9.2.2 Length

Place each sheet in the sample in turn on a flat rigid surface. Measure with a steel measuring tape of suitable length to the nearest 1 mm the length of each sheet along the centre line of the sheet.

9.2.3 Squareness

Place each sheet in the sample in turn on a flat rigid surface. Measure with a steel measuring tape of suitable length to the nearest 1 mm the distance between the diagonally opposite corners of each sheet and record to the nearest mm the difference between the two measurements.

9.2.4 Width

9.2.4.1 Plain sheets

Place each sheet in the sample in turn on a rigid surface. Measure with a steel measuring tape of suitable length to the nearest 1 mm across the width of the sheet.

9.2.4.2 Corrugated sheets

Place each of the sheets in the sample in turn on a flat rigid surface and measure with a steel measuring tape of suitable length to the nearest 1 mm across the width of the sheet. Choose at random a cross-section of the sheet and if, because of the springy nature of the sheet, the underside of the downwards corrugations or troughs are not all in contact with the supporting surface, apply sufficient pressure to the upper surface of the sheet to bring the lower surface into full contact with the supporting surface. Ensure that the application of pressure causes no deformation of the sheet other than that needed to bring the corrugations into contact with the rigid surface.

Place the width gauge appropriate to the type of sheet being tested across the sheet at any chosen cross section and at right angle to the sides of the sheet and adjust the gauge to fit firmly over the outermost corrugations. Determine whether the width of the sheet complies with the requirements of Table 1. Both edges of the corrugated sheet shall be turned upwards while measuring.

9.2.5 Pitch

With the sheet in contact with a flat surface, place a transparent graduated rule on edge across the sheet so that it rests perpendicularly on the crests of two adjoining corrugations far from the points of contact, and read the distance between them to the nearest 1 mm. Repeat the process to improve your results by taking the average of five readings for the distance between several crests.

NOTE Any other appropriate method may be used to measure the pitch.

9.2.6 Depth of corrugations

With the initial rule lying flat across the corrugations at the edge of the sheet, use another graduated rule or callipers to measure the perpendicular distance between the initial rule and the rigid support.

NOTE Any other appropriate method may be used to measure the pitch.

9.2.7 Tensile strength

From the sample in Clause 7, prepare a tensile test specimen, after stripping off coating, by cutting a strip 30 mm x 80 mm, such that the length of the specimen is transverse to the direction or rolling of the sheet. The portion of sheet from which the test piece is cut shall be carefully flattened. Determine the tensile strength of the specimen in accordance with ISO 6892-1.

If the tensile strength of the test specimen fails the requirements of 4.3, prepare two further test specimens and determine their tensile strength. If both specimens comply with the requirements, discard the results of the first specimen, but if either of the additional specimens fails to meet the requirements, deem the sheet and the lot to be defective.

9.2.8 Bend test and coating adherence test

A test specimen shall be selected in accordance with Clause 7 and shall be prepared to measure 10 mm in width and 120 mm in length.

It shall be cut with its length transverse to the direction of rolling of the sheet. Carefully bend the strip round a drum of diameter 38 mm (mandrels may also be used) until the edges of the specimen are approximately semi-circular.

If the specimen cracks, prepare and test two further specimens in the same way. If both these test specimens comply with the requirements of 4.4, 4.5 and 5.2.3, discard the results obtained on the first specimen, but if either of the two cracks at the bend, deem the sheet and lot to be defective.

9.2.9 Hardness test

The hardness test of the steel sheets shall be in accordance to ISO 6507-1 or ISO 6508-1.