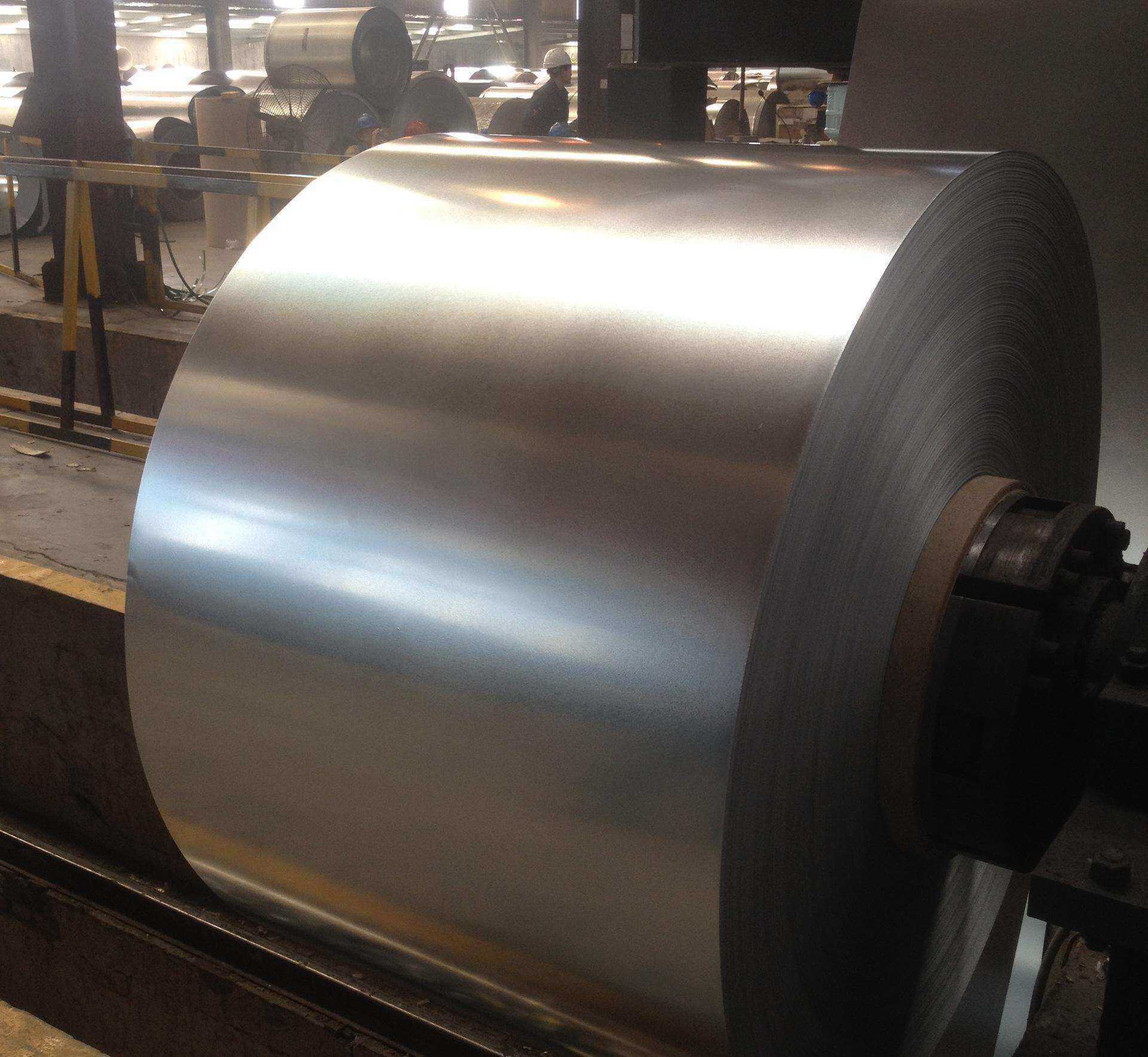

CR Coil Cold Rolled Steel Coil

CR Coil Cold rolled Steel coil are cold-worked steel sheets with specific tolerances, flatness and surface quality after a series of processing treatments. This process gives cold-rolled coils unique physical properties, making them widely used in automobiles, home appliances, building materials, and machinery manufacturing.

Cold-rolled coils are made from hot-rolled coils as raw materials and are rolled at room temperature below the recrystallization temperature. They include plates and coils, but are generally understood to be rolling using room temperature rolling materials. Europe and the United States mostly use 3~6 A continuous rolling mill serves as cold rolling equipment. At the same time, it is also the substrate for the production of galvanized steel sheets in coil and galvalume steel coil.

Advantage of CR Coil Cold Rolled Steel Coil

Cold rolling production can provide a large number of high-precision and superior-performance steel plates and strips. Its main feature is low processing temperature. Compared with hot rolling, it has the following advantages:

A. Cold-rolled coil products have a smooth surface, uniform color, precise size and uniform thickness. Not only does it give it a unique appearance, but more importantly, this surface treatment method gives the cold-rolled coil a good silvery effect, greatly improving its commercial value.

B. It is possible to obtain thin materials with excellent surface quality that cannot be produced by hot rolling, without defects such as pitting and pressed-in oxide scale that often occur in hot-rolled strip steel.

C. Cold-rolled coils have excellent processing properties and weldability. This means that during the production process, it can be easily cut, trimmed, stamped and welded to meet the specific needs of different industries. This flexible production method makes cold rolled coil widely used in various industries.

D. Cold-rolled coils have high strength and hardness, good wear resistance, long service life and can achieve high-speed rolling and full continuous rolling, with high productivity. This is because it has undergone cold working during the manufacturing process, making its internal grains smaller and denser, thereby improving its mechanical properties. This characteristic allows cold-rolled coils to remain stable when enduring high loads and complex working conditions, extending their service life.

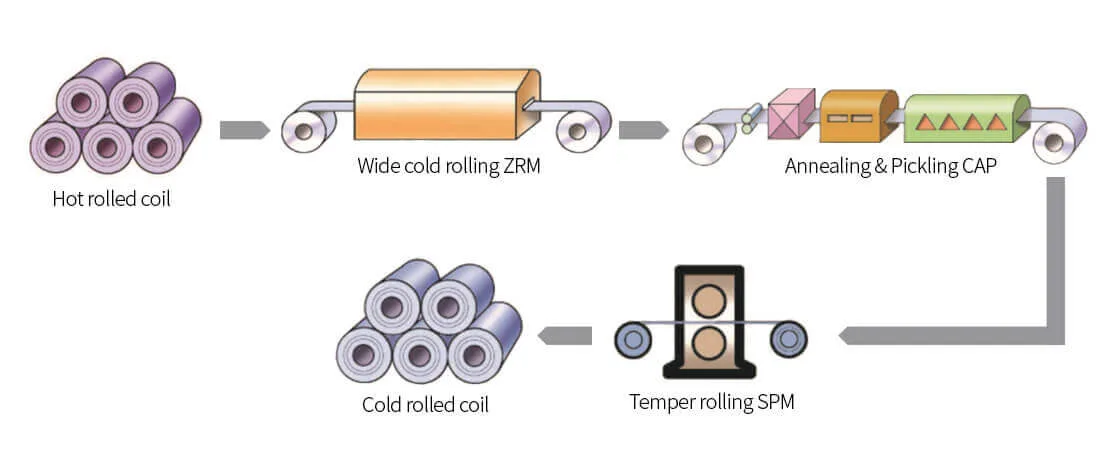

Process of CR Coil Cold Rolled Steel Coil

The production process of cold-rolled coils involves a variety of equipment, such as pickling equipment, cold rolling mills, annealing furnaces, galvanizing equipment, etc. These equipments are all high-precision and high-efficiency automated equipment. They can maximize the It can effectively reduce manual intervention and effectively improve production efficiency.

The process flow of cold-rolled coils is as follows:

1. Preparation for processing: The steel plate that has been produced needs to be prepared, which is like sharpening the knife for the subsequent cold rolling process. These preparations include cutting, smoothing, and rust removal, etc., to ensure the quality of subsequent cold rolling processing.

2. Pickling: Just like we take a bath, the cut steel plate also needs a “bath”. It uses pickling equipment to remove iron filings, rust slag, etc. to obtain a flatter and smoother surface.

3. Cold rolling: After pickling, the steel plate is like being sent to a “rolling mill”. This process can be divided into multiple stages. According to different cold rolling processing requirements, steel plate laying, pre-cooling, rough rolling, intermediate rolling, finishing rolling and other processes can be performed in sequence.

4. Annealing: During the cold rolling process, the steel plate will generate large strains and stresses. It’s like we need to relax after a stressful day at work. Annealing is such a “relaxation” process that can improve the physical properties after cold rolling, while reducing stress and ensuring product quality.

5. Galvanizing or spraying: Finally, in order to enhance the durability and anti-rust performance of the cold-rolled coil and make it more suitable for use in the external environment, we need to perform anti-corrosion treatments such as galvanizing or spraying.

Standard and Grade of CR Coil Cold Rolled Steel Coil

There are many standards and grades used in the cold-rolled coil market. The performance of the grades corresponding to each standard is roughly similar, but there are subtle differences. The following are the grades of several commonly used countries.

| Grade | GB/T 5213-2019 | JIS G 3141-2021 | EN10130-2006 | ASTM

A1008M-07 |

DIN 1623-1 |

| Commercial | DC01 | SPCC | DC01 | CS Type C | St12 |

| Stamping | DC03 | SPCD | DC03 | CS Type A, B | St13 |

| deep drawing | DC04 | SPCE | DC04 | DS Type A, B | St14 |

| extra deep drawing | DC05 | SPCF | DC05 | DDS | St15 |

| super deep drawing | DC06 | SPCG | DC06 | EDDS | St16 |

| Ultra super deep drawing | DC07 | — | DC07 | — | — |

Application of CR Coil Cold Rolled Steel Coil

Cold rolled coils are used in a wide range of applications, including automobiles, home appliances, building materials, machinery manufacturing and other fields. Especially in industries such as automobiles and home appliances, cold-rolled coils are being used more and more widely because of their good surface flatness, silver luster, and strong wear resistance.