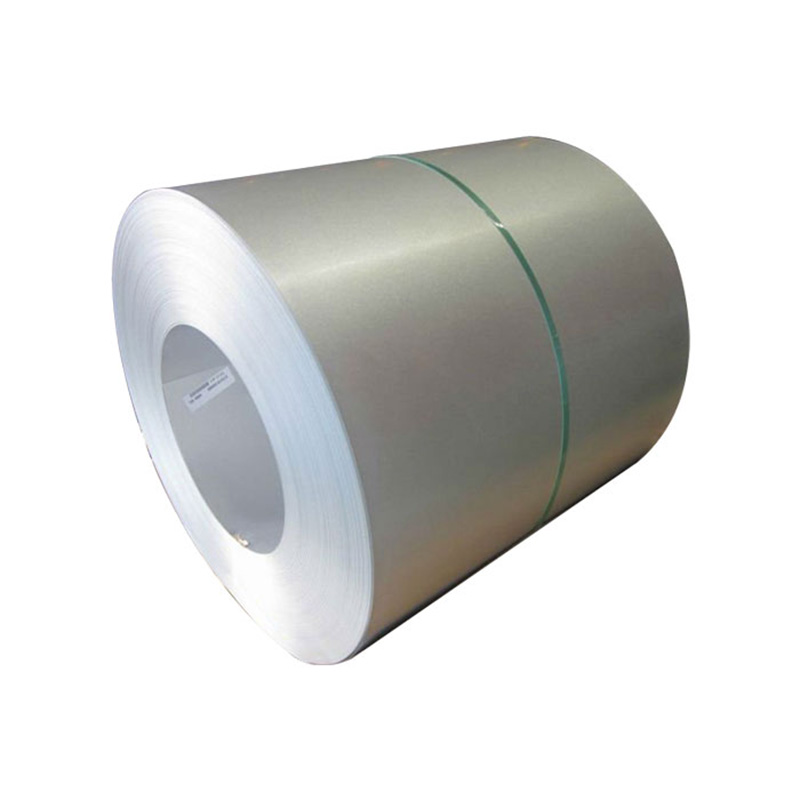

Color coated steel coil have better and more features.

Color coated steel coil are named because of being coated with various colors of paint. Color coated steel coil are lightweight, beautiful, good corrosion resistant, and can be directly processed.

Color coated steel coil are divided into color coated galvanized steel coil (PPGI steel coil) and color coated galvalume steel coil (PPGL steel coil) according to different substrates.

The paint types of color coated steel coil are divided into:

(1)Polyester (PE)

Good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, low cost.

(2)Silicon Modified Polyester (SMP)

The coating film has good hardness, abrasion resistance and heat resistance, as well as good external durability and chalk resistance, gloss retention, average flexibility, and moderate cost.

(3)High Durability Polyester (HDP)

Excellent color retention and UV resistance, excellent outdoor durability and chalk resistance, good film adhesion, rich colors, and excellent cost performance.

(4)Polyvinylidene Fluoride (PVDF)

Excellent color retention and UV resistance, excellent outdoor durability and chalk resistance, excellent solvent resistance, good formability, dirt resistance, limited color, high cost.

Color coated steel coil are widely used in advertising, construction, home appliance industry, electrical appliance industry, and furniture industry. Color coated steel coil have the following product features:

(1) Good durability, corrosion resistance and longer life than galvanized steel;

(2) Good heat resistance, less prone to discoloration at high temperature than galvanized steel;

(3) Good thermal reflectivity;

(4) Better processing performance and spraying performance than galvanized steel sheet;

(5) Good welding performance.

(6) Good price-performance ratio, durable performance and very competitive price.