How to choose color coated steel sheet?

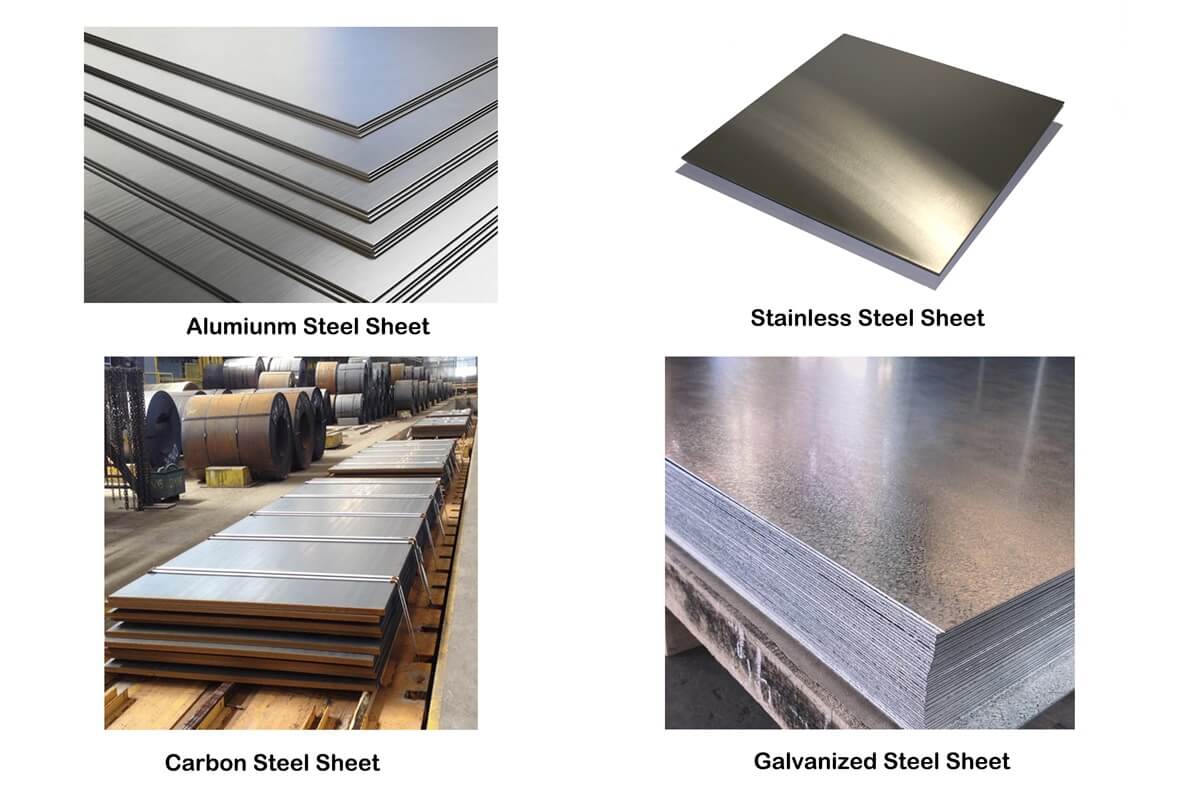

Color Coated Steel Sheet In order to improve the corrosion resistance of hot-dip galvanized steel sheet, improve their surface coloring, and prevent the surface zinc layer from directly contacting air, painting should be carried out. According to different purposes, suitable substrates and coatings should also be selected, and suitable coating methods should be used to produce color coated steel plates that meet the requirements.

In order to ensure good adhesion between the coating and the surface of the galvanized sheet, it is necessary to carry out chemical treatment on the galvanized surface. Firstly, clean the oil and dirt adhering to the surface of the galvanized sheet, otherwise it will affect the adhesion of the coating, so degreasing and cleaning are necessary. Then, chemical conversion treatment is carried out, usually to produce composite oxides or phosphate treatment on the galvanized surface. The former has good adhesion to the paint film, while the latter has good corrosion resistance. After chemical conversion treatment, it should be completely dry and painted without moisture.

Under normal circumstances, there are usually two aspects that need to be noted.

1. Selection of substrate (substrate strength, galvanizing amount, surface finishing, etc.).

2. Selection of paint coatings.

Due to the coating on the surface of the color coated steel sheet, there are many differences in the forming process compared to ordinary cold rolled sheet and galvanized sheet. Sufficient attention should be paid to the mechanical properties (such as yield strength, elongation) and coating properties (such as pencil hardness, T-bending value, impact energy) of color coated plates. The following points should be noted during post-processing:

(1) The shape of the parts is complex. When the degree of deformation is significant, multiple forming should be used. If formed in one go, the adhesion of the coating may be damaged due to excessive deformation.

(2) Set appropriate gaps based on factors such as mold shape, deformation characteristics, and process conditions, and consider coating thickness when setting gaps.

(3) The VI section generated during the processing is prone to corrosion, and necessary protective measures such as applying protective coatings and sealing with embedded rubber should be taken.

(4) During processing, the burrs on the cutting surface should be minimized as much as possible to prevent them from scratching the surface.

(5) The construction method should be pre installed in the factory as much as possible, and protective measures should be taken to prevent coating damage when sent to the site for installation.

(6) If damage is found to the surface of the coating, it should be promptly repaired with specialized repair paint to prevent corrosion at the damaged area.

Professional acceptance standards for professional color coated steel coil manufacturers:

Using your fingers to hit the color steel buckle, the metal sound of the color steel buckle with good material is obvious and crisp, while on the contrary, the metal sound is not obvious with poor material.

The surface shall not have obvious pores, bubbles, flow accumulation, or wrinkling.

The surface should not have pits, impurities, scratches, stains, or uneven coating.

The surface shall not be severely missed, the coating shall fall off, mix colors, or adhere.

The coating is not allowed to become brittle, yellow, or lose luster due to excessive baking.

No obvious color difference or uneven gloss is allowed on the surface.