Over time, any type of metal is prone to rust or corrosion, which is inevitable. Protecting the surface of galvanized steel is crucial to extending its lifespan. So, how can this be achieved? A simple method is to apply a clear coat to the surface.

Using a clear coat can extend the life of the steel and make it look better. Clear coat galvanized steel also helps prevent fading, oxidation, and damage caused by UV rays.

Here are some tips on how to apply a clear coat to galvanized steel and the types that may best suit your needs:

What is a Clear Coat?

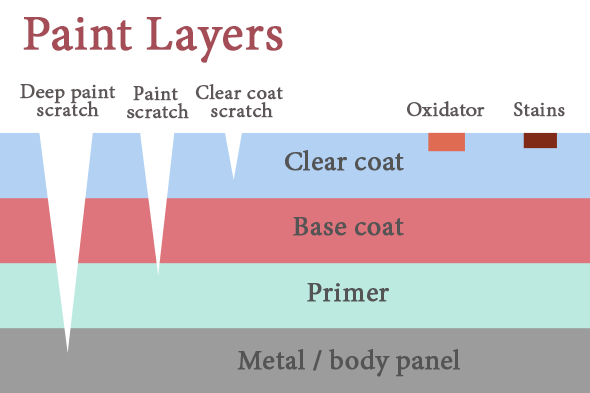

A clear coat is essentially a transparent layer of paint. In other words, it is a resin or colorless coating. Adding a clear coat can make the steel you’re painting look shiny and brand new again while also protecting the paint.

How to Apply a Clear Coat Galvanized Steel

- Surface Preparation

- Clean the Surface: Start by cleaning the galvanized steel to remove dirt, grease, or oil. You can use a mild detergent solution or a degreaser. Rinse thoroughly with water and allow it to dry completely.

- Remove White Rust: If the galvanized steel has developed white rust (zinc oxide), remove it with a vinegar solution (1:1 ratio of vinegar to water) or a specialized cleaner. Gently scrub with a non-abrasive pad, then rinse and dry the surface.

- Sand the Surface: Lightly sand the surface using fine-grit sandpaper (around 220 grit) to create a rough texture. This helps the clear coat adhere better.

- Priming the Surface (Optional but Recommended)

- Use the Right Primer: For better adhesion, especially when the steel will be exposed to harsh conditions, use a primer designed for galvanized metal. This step is crucial if the galvanized steel is in a high-humidity or corrosive environment.

- Let it Dry: Allow the primer to dry completely according to the manufacturer’s instructions before applying the clear coat.

- Applying the Clear Coat

- Choose the Right Clear Coat: Use a clear coat product suitable for metal surfaces, preferably one compatible with galvanized steel. Polyurethane or acrylic clear coats are typically recommended.

- Apply the Clear Coat: Use a brush, roller, or spray gun to apply the clear coat evenly across the surface. For best results, apply multiple thin layers rather than one thick layer. Let each layer dry before applying the next.

- Drying Time: It’s important to wait until the clear coat is dry before using the coated object. A waiting period of 36 to 48 hours is recommended.

- Final Inspection

- Check for Coverage: Ensure the entire surface is evenly coated, with no missed spots or streaks.

- Touch-up if Necessary: If any areas need extra coverage, touch them up with additional clear coat.

Types of Clear Coat

- Acrylic Clear Coat: This fast-drying clear coat gives metal a high-shine, glossy look.

- High-Performance Acrylic Clear Coats: These high-solid content coatings have a higher concentration of resin and fewer solvents or VOCs (Volatile Organic Compounds). Clear coats with more additives and higher solid content result in a thicker film after solvent evaporation. This type of coat dries slower and is more expensive than other types.

Clear coat galvanized steel layer

Considerations When Choosing a Clear Coat galvanized steel

- Transparency: This is one of the most important considerations when choosing a clear coat. If you want the metal to look refreshed, make sure to purchase a product that won’t cover the base color.

- Gloss Level: Remember that the gloss level should exceed 90 units so that the coated metal has a high-gloss finish and looks new.

- Ease of Application: Since most people aim to add a secondary coat, the application should not be difficult. Ensure the nozzle option you choose allows you to spray the coat evenly across the steel surface. This ensures that the surface is free from any flaws and remains smooth.

- Scratch Resistance: We all know that metal can be easily scratched, so adding an extra coat helps protect the surface. Choose a product that is scratch-resistant and offers UV protection.

Final Thoughts

Applying a clear coat is a great way to ensure the longevity of galvanized steel. Once you know what type you’re looking for, you should be able to choose the best product based on your plans.

When you need steel products, I suggest you prioritize and consider Witop Steel. Witop Steel is a steel manufacturer specializing in the production of galvanized Steel, galvalume steel, color-coated coils and color steel tiles. If you need to find other steel suppliers, you are welcome to contact us and we will be happy to provide you with professional help.