Chromatic aberration, also referred to as color fringing, is a common issue that occurs in images and photographs taken with optical instruments such as cameras and microscopes. In the context of PPGI/PPGL steel coils, chromatic aberration can also occur during the production process, leading to inconsistencies in color and potentially affecting the overall quality of the steel coil. Several factors can contribute to the occurrence of chromatic aberration on PPGI/PPGL steel coils, including the composition of the coating materials, the manufacturing process, and the conditions under which the coils are stored and transported.

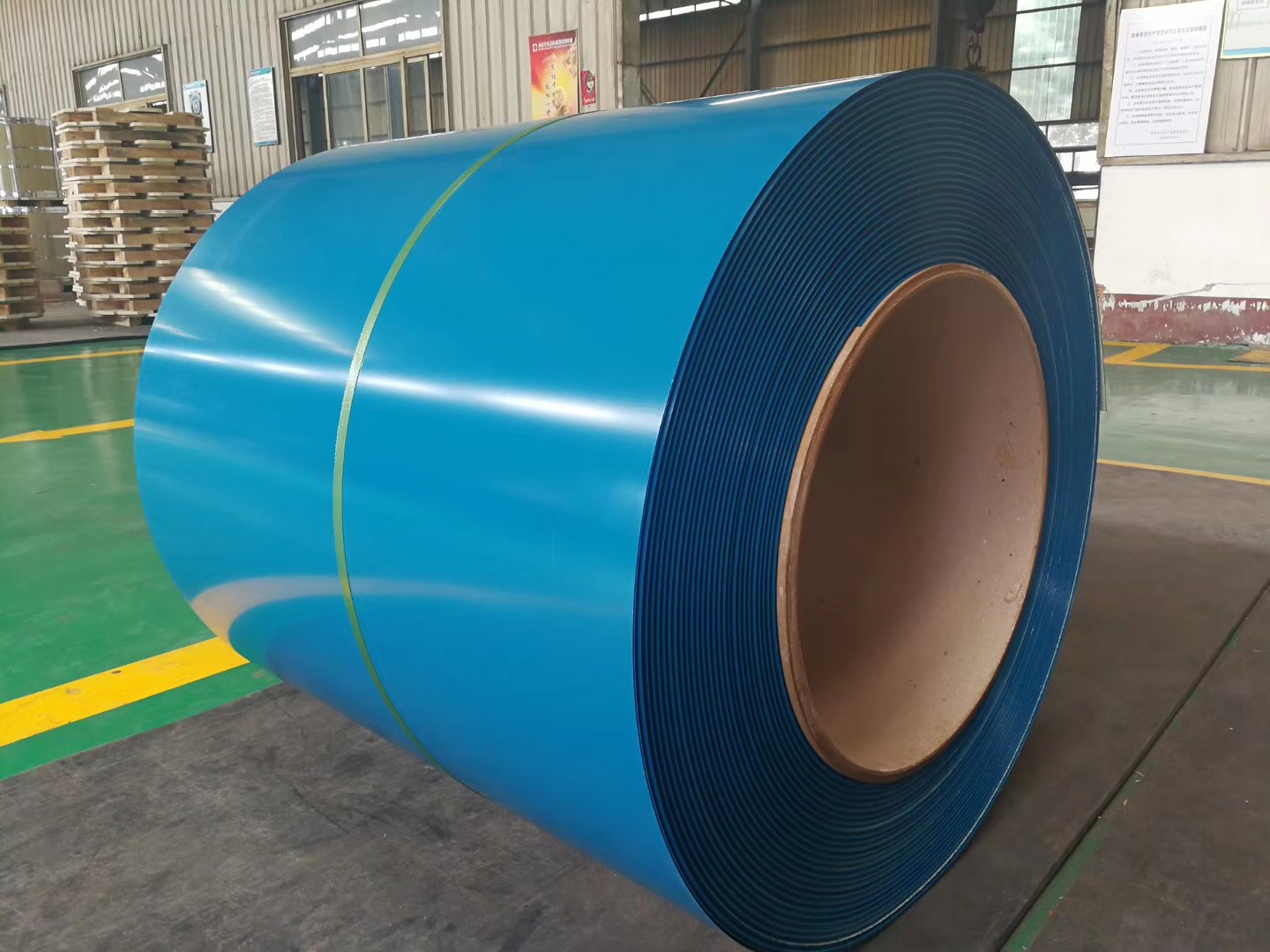

What are the reasons for the color difference on the surface of PPGI PPGL color coated steel coil?

Paint, painting film thickness, viscosity, plate temperature, cooling water, curing oven, uneven or no stirring of paint will cause color difference on the surface of color coated galvanized/aluzinc steel roll.

1. Paint

1. Refers to the color difference (light color) of the paint in the same batch or in the bucket.

2. Paint pigments and fillers are different.

3. When changing to a new batch or new paint, it results in color difference from the feed port to the return port.

4. Features: It extends from the side of the feed port to the direction of the return port, and it is distributed in a strip shape and gradually widens.

2.Painting film thickness

1. It refers to the color difference caused by the different thickness of the painting film.

2. The viscosity of the coating and the pressure change between the coating rollers.

3. Refers to different color coated rollers or both sides of the same color coating roller.

4. There is no significant change, but there are a big difference between steel coils.

3. Stickiness

1. Refers to the color difference caused by low or high viscosity on paint.

2. The viscosity in the barrel is very different from the viscosity of the barrel paint.

3. After a few minutes of paint change, the color difference of the ribbon appears on the side of the feeding port.

4. This problem is the same as the previous film thickness variation. Essentially, a high or low viscosity will eventually cause a change in film thickness.

3. Plate temperature

1. The color difference are caused by too high or too low temperature of steel plate.

2. The furnace temperature setting is unreasonable and the feeding is wrong.

3. Phenomenon: The gloss of the layout is not high, and the MEK is unqualified.

4. There is no problem with the same panel, but different steel coils vary greatly.

5. Cooling water

1. Color difference are caused by water quality.

2. The water quality is not good, and the effect of the press roll is not good.

3. Phenomenon: The plate surface is black and the gloss is not high.

4. Features: surface dirt can be wiped off with cotton yarn.

6. Curing furnace

1. Refers to the color difference of both sides of the steel plate.

2. The temperature of the drive side and the operation side of the curing oven is not uniform.

3. Features: There is no obvious chromatic aberration in the longitudinal direction, and the chromatic aberration in the lateral direction is large (similar to the color difference in film thickness on both sides).

7. The paint is not evenly mixed or not stirred well.

1. It is distributed on the board in a strip shape.

2. Paint layering results in viscosity differences.

8. Other Reason

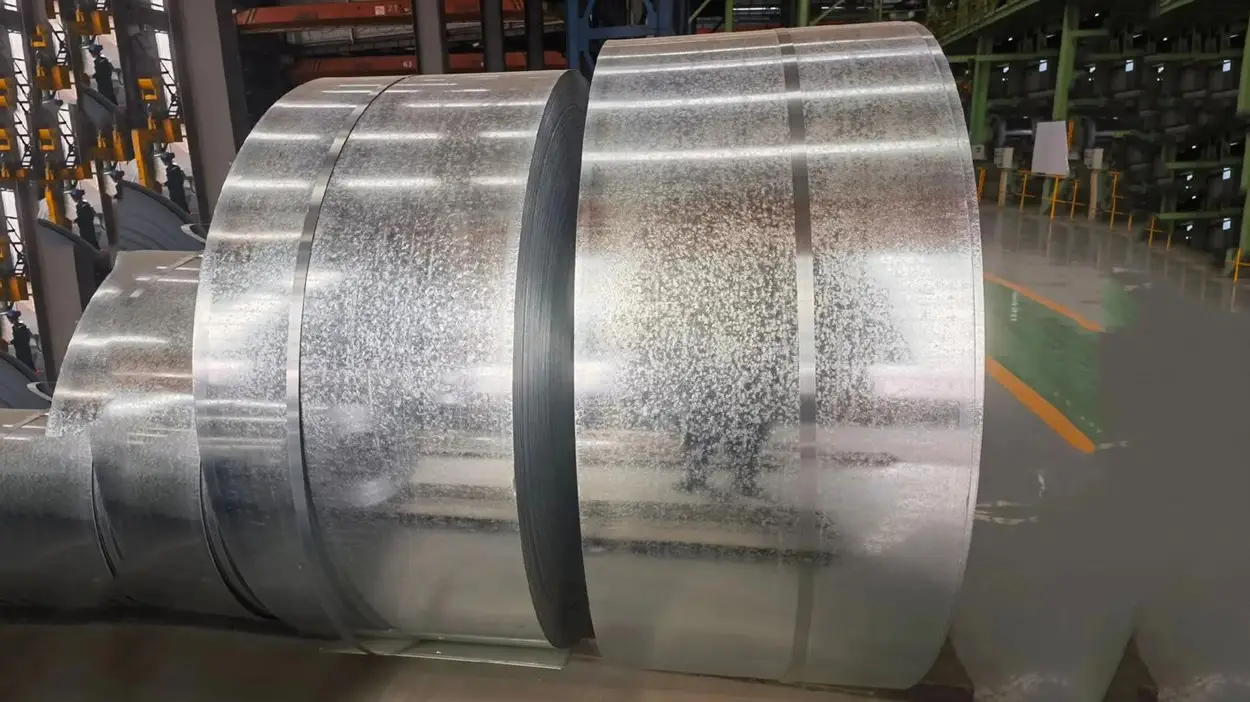

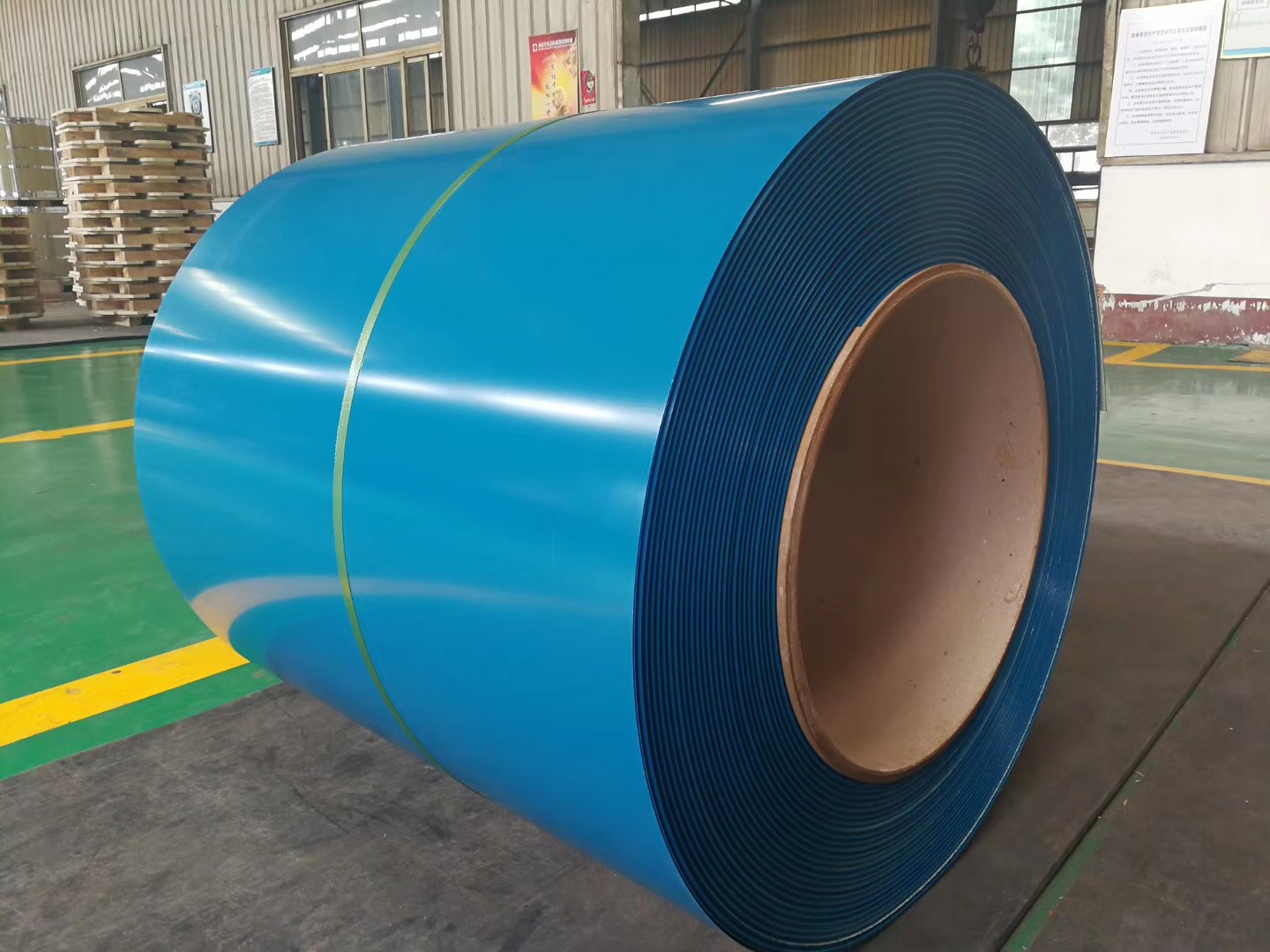

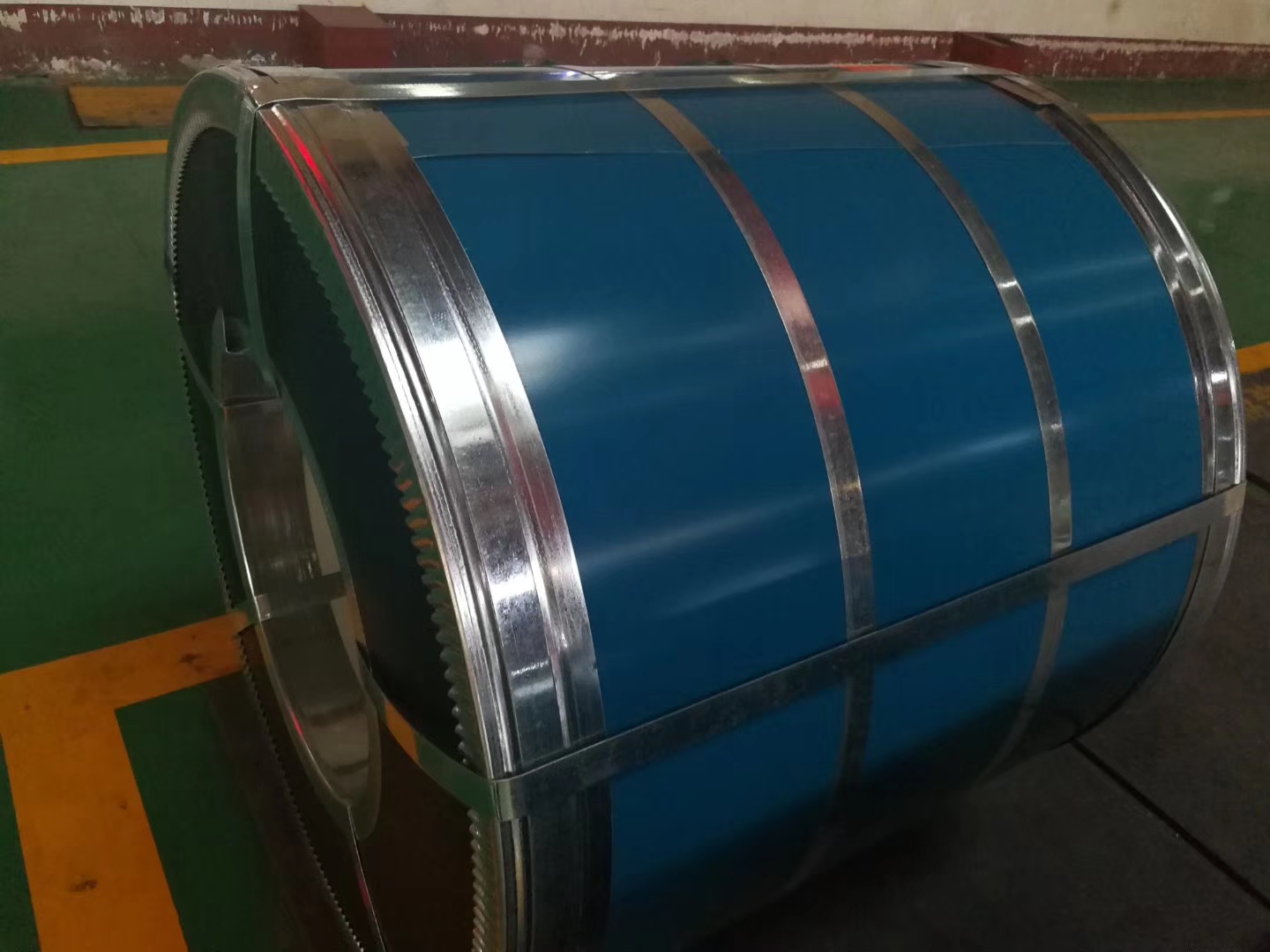

One of the primary causes of chromatic aberration on PPGI/PPGL steel coils is the composition of the coating materials used in the manufacturing process. PPGI (Pre-Painted Galvanized Iron) and PPGL (Pre-Painted Galvalume) steel coils are coated with a layer of paint or a combination of paint and zinc to protect the underlying steel from corrosion. The quality and composition of the coating materials can vary depending on the manufacturer and the specific application of the steel coil. If the coating materials contain impurities or are not mixed properly, this can result in color inconsistencies and chromatic aberration in the final product.

Another factor that can contribute to chromatic aberration on PPGI/PPGL steel coils is the manufacturing process itself. The process of applying the coating materials to the steel coils involves several steps, including cleaning, priming, painting, and curing. Each of these steps must be carried out with precision and care to ensure that the coating materials are applied evenly and adhere properly to the steel surface. Any deviations or errors in the manufacturing process can lead to color discrepancies and chromatic aberration in the finished product.

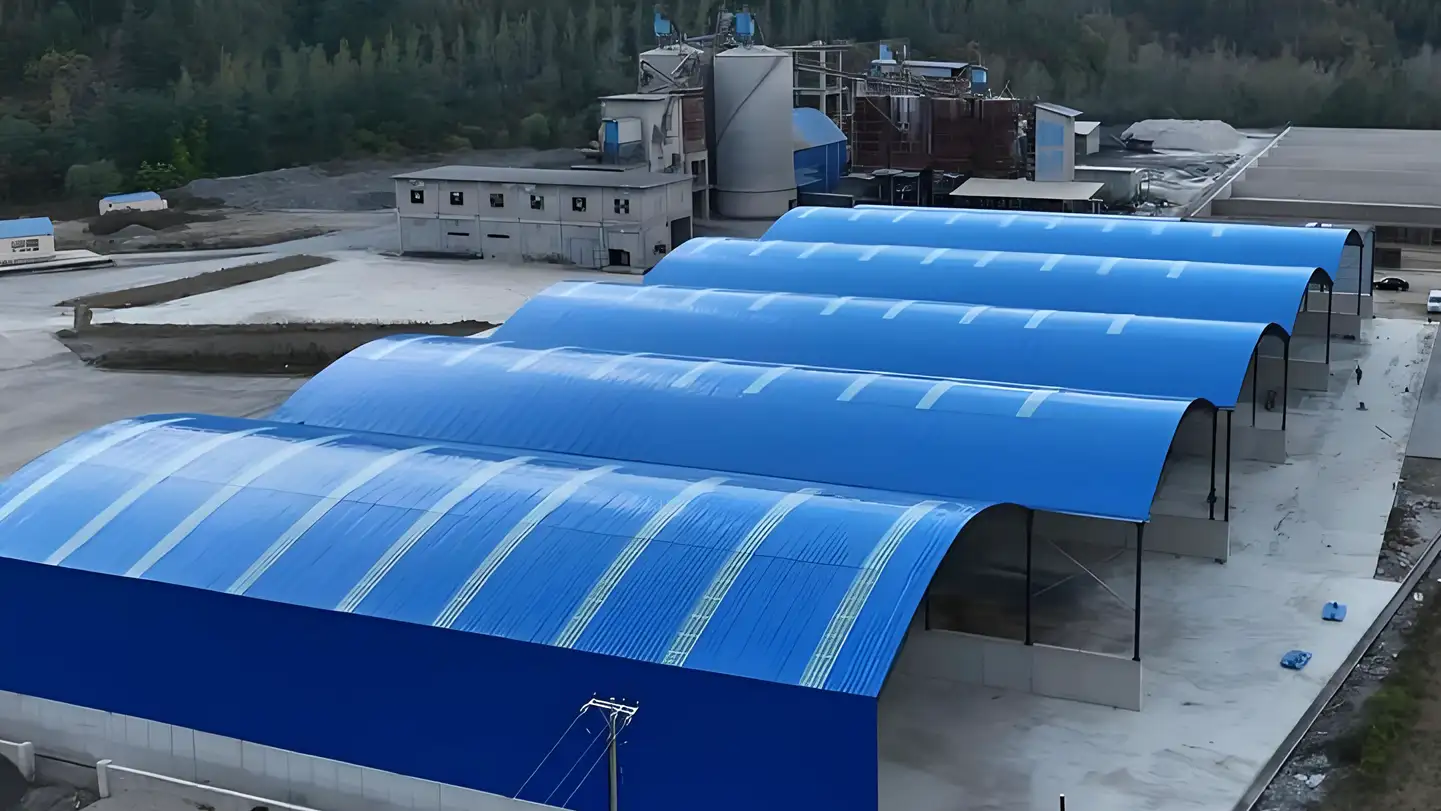

Additionally, the conditions under which the PPGI/PPGL steel coils are stored and transported can also influence the occurrence of chromatic aberration. Steel coils are typically stored in warehouses or outdoor storage yards before being shipped to customers or construction sites. Exposure to extreme temperatures, humidity, or sunlight can cause the coating materials on the steel coils to degrade or discolor, leading to chromatic aberration. Proper storage and handling of the steel coils are essential to prevent color inconsistencies and maintain the overall quality of the product.

In conclusion, chromatic aberration on PPGI/PPGL steel coils can be caused by a variety of factors, including the composition of the coating materials, the manufacturing process, and the storage and transportation conditions. To minimize the occurrence of chromatic aberration, manufacturers must carefully select high-quality coating materials, follow strict manufacturing protocols, and ensure proper storage and handling of the steel coils. By addressing these key factors, manufacturers can produce PPGI/PPGL steel coils that are free from color inconsistencies and meet the highest standards of quality and durability.

Get Expert more advice and suggestions, please send the message now.