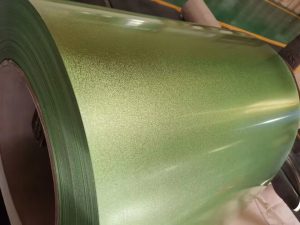

Hot dip aluminum-zinc steel(aluzinc steel/galvalume steel) sheet is a kind of pre coated steel plate, which is made of cold rolled steel plate of various strength, thickness and specifications as the base material and is hot-dip plated with a layer of Aluminum and zinc coating on both sides. The content percentage of the coating composition is 55% Al, 43.5% Zn and 1.5% Si, which combines the physical protection and high durability of Al as well as the electrochemical protection characteristics of Zn. In addition, hot-dip aluminum-zinc steel plate has a highly decorative bright silver gray color and regular patterns on the surface, and has a textural convex surface.

Hot dip aluminum zinc steel sheet is widely applied in industrial products such as construction, automobile and household appliances:

Construction industry: light steel keel, building floor, roof, exterior wall, garage door, rolling shutter door, fence and shutter of various civil and industrial buildings.

Household appliances: the shell and bottom plate of various household appliances, ovens, explosion-proof strips, external covers of air conditioning and ventilation systems, solar water heaters, and electrical components.

Automobile industry: shell, inner plate, bottom plate, muffler, heat shield of exhaust pipe and catalytic converter, parts at the bottom of automobile body, road sign plate.

Industrial instruments: electric control cabinet, industrial freezer, vending machine, etc.

1、Available specification range of WITOP STEEL

| Type | Thickness (mm) | Width (mm) | Length ( or Coil Inner Diameter)(mm) |

| Steel Plate | 0.12-1.50 | 600-1250 | 1000-6000 |

| Steel Coil | 0.12-1.50 | 600-1250 | 508 or 610 |

| Steel Strip | 0.12-1.50 | 20-600 | 508 or 610 |

2、Standard and steel grade of WITOP STEEL

| Type of Material | BAOSTEEL Standard | Steel Grade | Notes |

| Cold Forming Steel | Q/BQB425 | DC51D+AZ | Suitable for Cold Forming |

| DC52D+AZ | |||

| Structural Steel | S250GD+AZ | Suitable for Structural Steel | |

| S300GD+AZ | |||

| S350GD+AZ | |||

| S550GD+AZa | |||

| a:applicable to products with incomplete annealing after rolling hardening | |||

3、Classification and code of coating type of WITOP STEEL

| Type | Item | Abbreviation |

| Coating Type | Aluminum zinc alloy coating | AZ |

| Coating weight g/m2 | 20/20, 30/30, 40/40, 50/50, 60/60, 75/75, 90/90 | |

4、 Classification and code of surface treatment of WITOP STEEL

| Item | Type | Abbreviation | Notes |

| Surface Treatment | Chromate Passivation | C | This surface treatment can reduce the black rust on the product surface during transportation and storage. |

| Oiled | O | This surface treatment can reduce the black rust on the product surface, which is generally not used as rolling oil and stamping lubricating oil for post-processing. | |

| Chromate Passivation+Oiled | CO | This surface treatment can further reduce the black rust on the product surface | |

| Anti Finger Print Film | AFP | This surface treatment has no trace on the surface after finger touching, which can reduce the black rust on the product surface.

No-Color AFP, Golden-color AFP, Green-color AFP, Blue-color AFP. |

|

| Untreated | U | This surface is easy to cause black rust, so the user should consider carefully when selecting. |

5、Hot-dip aluminum zinc comparison table of similar grades of WITOP STEEL

| Q/BQB 425-2009 | AS 1397-2001 | EN 10215-1995 | ASTM A792M-02 | JIS G 3321:1998 | ISO 9364-2001 |

| DC51D+AZ | G2+AZ | DX51D+AZ | CS type B、type C | SGLCC | 01 |

| DC52D+AZ | G3+AZ | DX52D+AZ | DS | SGLCD | 02 |

| S250GD+AZ | G250+AZ | S250GD+AZ | 255 | — | 250 |

| S300GD+AZ | G300+AZ | — | — | — | — |

| S350GD+AZ | G350+AZ | S350GD+AZ | 345 Class1 | SGLC490 | 350 |

| S550GD+AZ | G550+AZ | S550GD+AZ | 550 | SGLC570 | 550 |