What is A36?

A36 generally refers to ASTM A36, which is a widely used carbon steel material standard defined by the American Society for Testing and Materials (ASTM). ASTM A36 is a widely used low-carbon structural steel with good weldability. Due to its excellent performance, ASTM A36 is used to manufacture welded and bolted metal structures for industrial and civil buildings and bridge construction. ASTM A36 steel is also used to manufacture products and parts for general construction and mechanical engineering purposes. et al. conducted an in-depth analysis of ASTM A36 in this article, including its chemical composition, mechanical properties, common applications, and the advantages of making it the first choice for various structural uses.

1. Chemical composition of ASTM A36

The chemical composition of ASTM A36 mainly includes elements such as carbon (C), silicon (Si), manganese (Mn), phosphorus (P) and sulfur (S). Among them, carbon is the main component that affects the performance of steel. The carbon content of ASTM A36 is generally between 0.25% and 0.35%, which is a low-carbon steel spindle. Silicon and manganese can increase the strength and endurance of phosphorus. Harmful elements such as phosphorus and nitrogen should be used as low as possible.

| Chemical Requirements | ||||

| Thickness, inches | Up to 3/4″ | Over 3/4″ to 1-1/2″ | Over 1-1/2″ to 4″ | Over 4″ |

| Carbon, max % | 0.26 | 0.27 | 0.28 | 0.29 |

| Manganese, % | 0.60 – 0.90 | 0.60 – 0.90 | 0.60 – 0.90 | |

| Phosphorous, max % | 0.04 | 0.04 | 0.04 | 0.04 |

| Sulfur, max % | 0.05 | 0.05 | 0.05 | 0.05 |

| Silicon, max % | 0.4 | 0.4 | 0.4 | 0.4 |

| Copper, min % when copper is specified | 0.2 | 0.2 | 0.2 | 0.2 |

The chemical composition of ASTM A36 ensures a good balance between elongation and strength of the steel.

Main components include:

• Carbon (C): 0.25-0.29% Carbon is a key element that adds hardness and strength to steel while maintaining its ductility.

•Manganese (Mn): 1.03% Manganese contributes to the strength and hardness of steel and improves its shapeability and forgeability.

• Phosphorus (P): 0.04%max- Phosphorus can increase strength and hardness, which is kept low in structural steel to avoid brittleness.

•Sulfur (S): 0.05%max- Similar to phosphorus, sulfur may make steel brittle, therefore, kept to a minimum.

•Silicon (Si): 0.28%max- Silicon acts as a deoxidizer, removing oxygen from steel and improving its strength and hardness.

• Copper (Cu): 0.20% maximum Copper is added to improve corrosion resistance, especially in weathering steel.

•Iron (Fe): Balanced iron form of foundation that provides bulk of the material’s properties (Triton Board)

•. ASTM A36 steel is designed to provide a blend of strength, weldability, and ease of fabrication, which is why it is Widely used in the structural steel market.

2. A36 Equivalent

American Standard A36, the tensile strength is 58~80 Ksi (about 400~550MPa), and the yield strength is 36 Ksi (about 250MPa).

European standard S275, the tensile strength is 430~580 MPa, and the yield strength is >=275MPa.

Chinese standard Q255, the tensile strength is 410~550 MPa, and the yield strength is 255MPa.

Japanese standard SS400, the tensile strength is 400~510 MPa, and the yield strength is 245Mpa.

Mechanical properties of ASTM A36

The mechanical properties of ASTM A36 include yield strength, tensile strength, elongation and impact toughness. According to ASTM standards, ASTM A36 has a yield strength of 250MPa, a tensile strength of 400-550MPa, an elongation of not less than 20%, and an impact toughness of not less than 27J at 0°C.

ASTM A36 is known for its impressive mechanical properties, making it suitable for a variety of structural applications. Key attributes include:

• Yield Strength: ASTM A36 steel has a minimum yield strength of 36,000 psi (250 MPa). Yield strength is the stress at which a material begins to plastically deform.

• Tensile Strength: Tensile strength ranges from 58,000 to 80,000 psi (400-550 MPa). This is the maximum stress that ASTM A36 can withstand when stretched or pulled before necking.

• Elongation: The elongation of a material is typically 20% at 8 inches and 23% at 2 inches. This property indicates the steel’s ductility, reflecting its ability to withstand deformation without breaking.

These characteristics highlight ASTM A36’s ability to withstand a variety of loads, making it ideal for heavy construction projects. Its moderate yield strength and high elongation ensure the material is able to absorb significant stress without cracking, providing safety and reliability in structural applications. These performance indicators make ASTM A36 a steel with good plasticity and toughness, suitable for the manufacture of various structural parts and components.

| A36 Mechanical Property | ||

| ASTM A36 Hot Rolled Steel Plate | ||

| Mechanical Properties | Metric | Imperial |

| Tensile Strength, Ultimate | 400 – 550 MPa | 58000 – 79800 psi |

| Tensile Strength, Yield | 250 MPa | 36300 psi |

| Elongation at Break (in 200 mm) | 0.2 | 0.2 |

| Elongation at Break (in 50 mm) | 0.23 | 0.23 |

| Modulus of Elasticity | 200 GPa | 29000 ksi |

| Bulk Modulus (typical for steel) | 140 GPa | 20300 ksi |

| Poissons Ratio | 0.26 | 0.26 |

| Shear Modulus | 79.3 GPa | 11500 ksi |

Main features of ASTM A36

ASTM A36 has several properties that make it a flexible and valuable material:

Weldability: Steel can be easily welded using a variety of welding techniques, including arc welding, mig welding and argon arc welding. This is due to its low carbon content, which helps prevent hardening and cracking during welding procedures.

Machinability: It has good machinability and an amount of about 72%. This means that it can be easily cut, drilled, and processed into different shapes and sizes, making it suitable for a variety of manufacturing processes.

Ductility: The material can be formed in different shapes by hot and cold, including sheets, plates, strips, and more. Its nature is to enhance its ductility, allowing it to bend or will not break. These characteristics make ASTM A36 suitable for a wide range of industrial applications, providing flexibility in manufacturing and construction processes.

Application of ASTM A36

The versatility and durability of ASTM A36 steel make it a popular choice for a wide range of industries

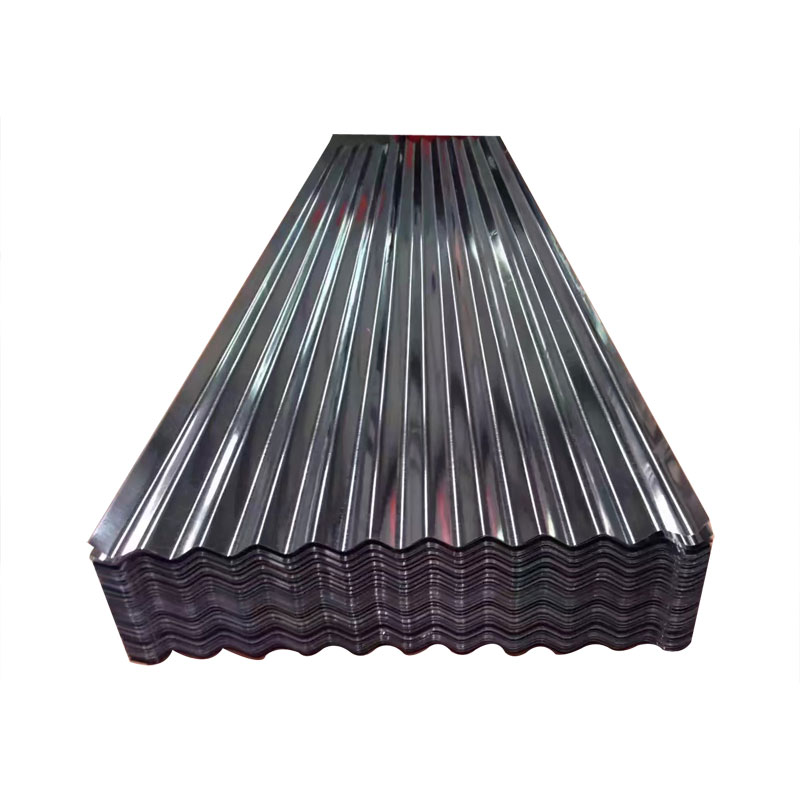

1. Construction industry: ASTM A36 is widely used in the manufacture of building steel structures, bridges, towers, roof panels, wall panels, and other building components. Its good weldability and toughness make the building structure more stable and safe, and its strength and durability make it ideal for beams, columns and rebar.

2. Machinery manufacturing: ASTM A36 is also commonly used in the field of machinery manufacturing, such as manufacturing structural parts of equipment such as machine tools, vehicles, ships, pressure vessels, etc. Their excellent mechanical properties make these devices more durable and reliable.

3. Other Areas: ASTM A36 can also be used to manufacture industrial equipment such as oil pipelines, storage tanks, conveyor belt supports, as well as to make various steel structural parts and components.

In addition, ASTM A36 is commonly used in the production of sidewalks, ramps, and stairs due to its ability to support enormous weights while maintaining structural integrity.

Machinability and Weldability of ASTM A36

1. Machinability: ASTM A36 has good processing performance and can be used for cutting, drilling, milling, bending and other machining operations. During the machining process, it is necessary to pay attention to controlling the processing temperature and speed to avoid excessive stress and deformation.

2. Weldability: ASTM A36 has excellent welding performance and can be joined by various welding methods, such as manual arc welding, gas shielded welding, submerged arc welding, etc. During the welding process, it is necessary to select the appropriate welding materials, welding parameters and preheating temperature to ensure the quality and performance of the welded joints.

Advantage and Disadvantages of ASTM A36

-

Advantages:

- ASTM A36 has good weldability, machinability, and toughness, and is suitable for the manufacture of various structural parts and components. Its strength is moderate, easy to process and weld, and the cost is low, so it has been widely used in many fields. The widespread use of ASTM A36 steel can be attributed to several key advantages: • Cost-effective: Its relatively low cost compared to other structural steels makes it an economical option for larger projects. • Availability: ASTM A36 is widely used in the market, which ensures a steady supply of ongoing projects. • Corrosion Resistant: When galvanized, ASTM A36 can resist corrosion, extending its service life and reducing maintenance costs. This makes it suitable for outdoor and industrial applications where exposure to the elements is a concern. • High strength-to-weight ratio: This property allows for the construction of strong and lightweight structures, which is particularly important for reducing the overall weight of buildings and vehicles. The material’s ability to provide a strong and stable foundation while being cost-effective makes it the preferred choice for many structural applications

-

Disadvantages:

- ASTM A36 has relatively low strength and hardness, making it unsuitable for use in manufacturing equipment that needs to withstand extremely high loads or extreme environments. In addition, it is less resistant to corrosion and requires measures such as surface treatment or painting to improve its service life.

ASTM A36 is a base timber in the construction and manufacturing industry because of its versatility, strength, and affordability. Its good mechanical properties, ease of fabrication and wide availability make it an ideal choice for numerous structural and industrial applications. Whether used in the construction of buildings, bridges, or machinery, ASTM A36 steel provides reliability and durability. For engineers, architects, and manufacturers looking for a reliable steel structure, ASTM A36 continues to be an excellent choice, offering a perfect blend of strength, performance, and cost-effectiveness.

As a widely used low-carbon structural steel, ASTM A36 plays an important role in construction, machinery manufacturing, bridge construction, and other fields. Knowledge of its chemical composition, mechanical properties, application areas, processing and welding helps us to better select and use this steel. At the same time, we also need to pay attention to its advantages and disadvantages, so as to give full play to its advantages in practical applications and avoid potential risks. For more detailed specifications and further inquiries, consult with the material supplier or technical expert for advice to ensure that ASTM A36 meets the specific needs of the project.

When you need steel products, I suggest you prioritize and consider Witop Steel. Witop Steel is a steel manufacturer specializing in the production of galvanized Steel, galvalume steel, color-coated coils and color steel tiles. If you need to find other steel suppliers, you are welcome to contact us and we will be happy to provide you with professional help.