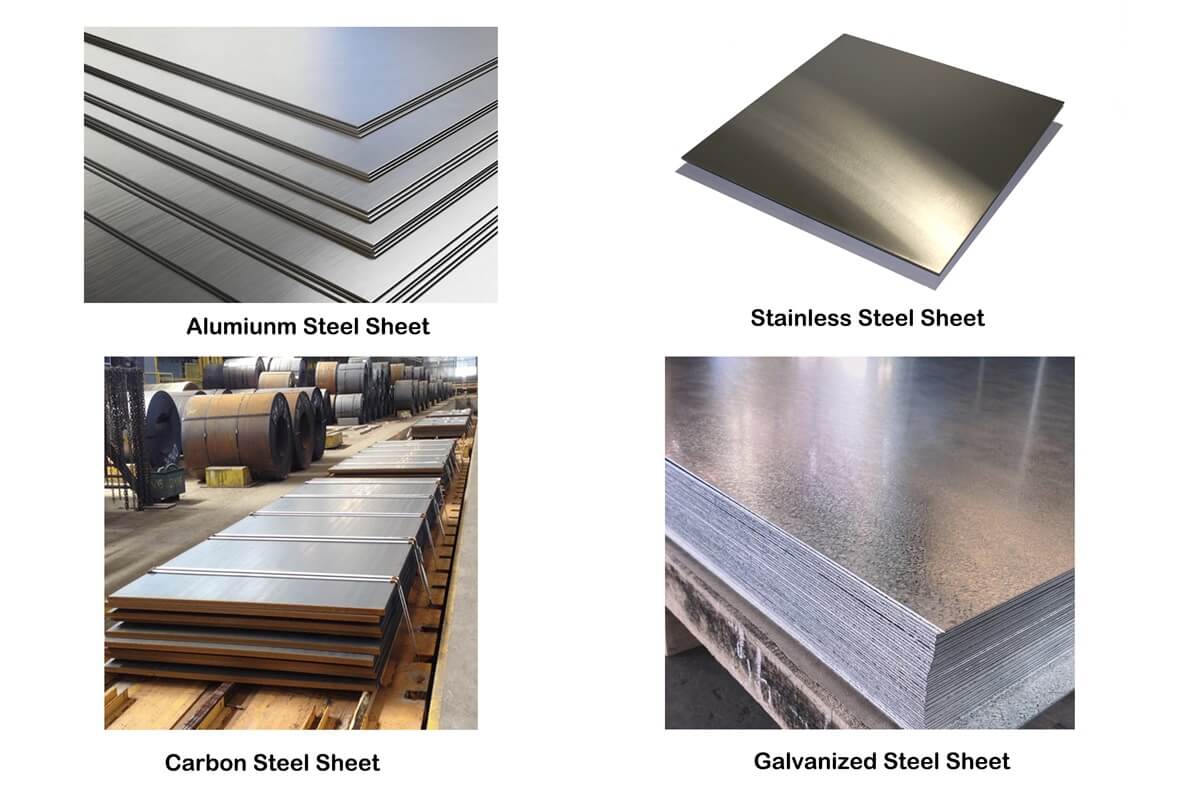

The price advantage is the main reason for the significant increase in steel exports from China. In the first half of 2023, the prices of galvanized steel sheets in China and globally showed a trend of first rising and then falling. Chinese steel prices are still at a low level internationally. In the first half of 2023, the FOB export price difference between Japan and China for galvanized steel sheets remained at $40-70 per ton for a long time. The FOB export price difference between Türkiye and China for galvanized steel coils has been maintained at 100-200 US dollars/ton for a long time, and China has obvious advantages in the export price of galvanized coils.

Due to high costs and force majeure factors, overseas steel companies’ production has decreased and there is a supply gap, providing opportunities for China’s galvanized steel coil exports. In the first half of 2023, among the top 10 global steel producing countries (regions), only China, India, Russia, and Iran achieved year-on-year growth in production, while other countries experienced varying degrees of decline. Specifically, Japan’s crude steel production was 43.8 million tons, a year-on-year decrease of 4.7%; The crude steel production in the United States was 39.9 million tons, a year-on-year decrease of 2.9%; South Korea’s crude steel production reached 33.7 million tons, a year-on-year decrease of 0.5%; The estimated production of crude steel in Germany is 18.5 million tons, a year-on-year decrease of 5.3%; Brazil’s crude steel production was 16 million tons, a year-on-year decrease of 8.9%; Türkiye’s crude steel output was 15.9 million tons, down 16.3% year on year.

From a regional perspective, crude steel production in Japan and South Korea has slightly decreased; A significant decline in the European region; There has also been a significant decline in the Americas region. The main reason is:

Türkiye is the largest steel producer in Europe, and its output ranks seventh in the world. In February 2023, a strong earthquake occurred in Türkiye. Erdmeir and Isdemir, as the few long process steel mills in Türkiye that can produce plates, suddenly stopped production, and the plate supply gap became prominent, which also led to a significant increase in Türkiye’s demand for imported plate resources.

The production of the 27 EU countries in the first half of the year was 66.3 million tons, a year-on-year decrease of 10.9%, with a significant decrease. On the one hand, after the Russia-Ukraine conflict, the EU’s natural gas supply is still unstable. Although other countries supplement natural gas resources, the supply uncertainty is high. There is still a periodic shortage of natural gas in Europe, leading to the European electricity price still higher than the level before the Russia-Ukraine conflict. Due to the fact that electric furnace steelmaking accounts for about 45% of the overall proportion in Europe, high electricity prices have led to higher production costs and lower production enthusiasm among European steel companies. On the other hand, the PMI level of the manufacturing industry in the eurozone has been below the boom and bust line for 13 consecutive months, with sluggish performance in the manufacturing industry. The German economy has even fallen into a technical recession, and the support for steel consumption is insufficient.