10 problems low price supplier

Top 10 problems low price supplier when choosing a low-cost metal coil supplier may seem like an attractive way to cut back on expenses and purchase costs, but there are significant risks involved and may end up costing more money and time to maintain the current situation. There is a situation. I have listed some problems that may arise when choosing a low-price supplier:

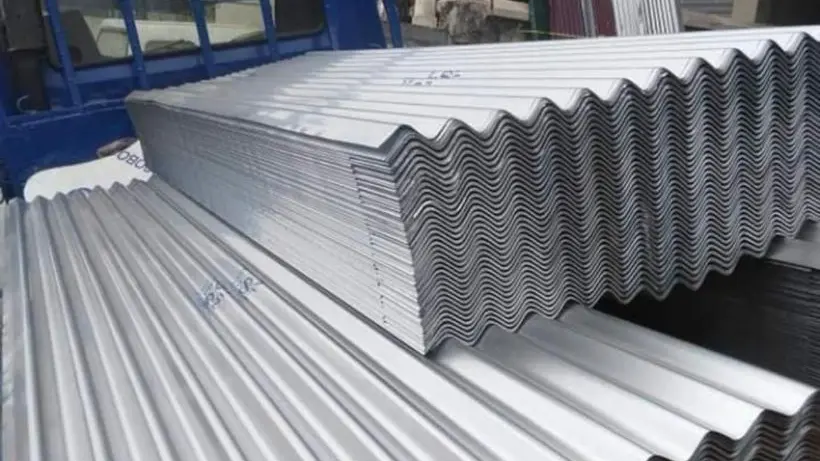

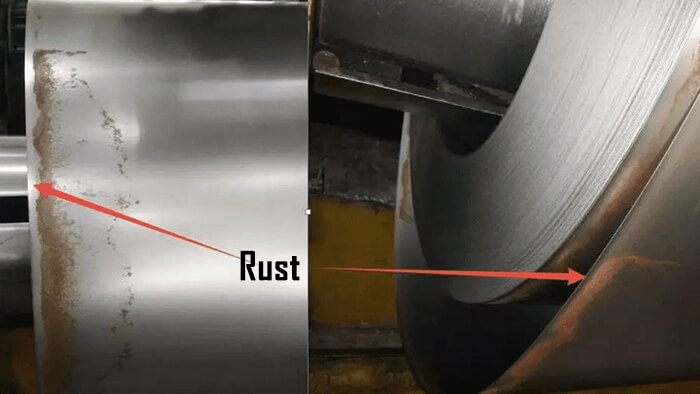

1. Reduced quality

Because the quoted cost is relatively low, low-price suppliers may use lower-quality raw materials in the manufacturing process, resulting in lower product quality. This reduction in quality can manifest itself in a variety of ways, such as changes in product thickness, surface defects, reduced coating thickness, run meters problem, and reduced quality levels of the substrate. In the steel industry, product accuracy and durability are crucial. When product quality is reduced, it may cause the product to fail to meet market requirements, increase after-sales costs and rework, and may even be used by competitors. High risk of substitution, and loss of market share.

2. Reliability and timely delivery

Generally, low-price suppliers may also have great risks in terms of reliability and timely delivery; because low-price suppliers need to postpone the production cycle of orders with lower profits to ensure the normal delivery of other orders; this may It will cause your order not to be delivered on time, which will affect your order production cycle and even the company’s operations, especially for goods with particularly strong seasonal requirements. If you cannot receive the goods in time, you may have the best sales season of the year, such as roofing. Building material dealers need to be in some countries and regions before the rainy season comes, which is the best sales season.

3. Poor customer support

Low-price suppliers often maintain profits by reducing customer service and technical support. This can result in delays in communication, unresolved issues, and lack of support when problems arise. In situations that require quick resolution or technical assistance, support can lead to costly production delays and setbacks.

4. Unreliable supply chains

Low-price suppliers may not have strong logistics and inventory management systems, resulting in unreliable delivery schedules. Late shipments can disrupt your production schedule, cause bottlenecks, and result in missed deadlines. Additionally, if a low-price supplier doesn’t have enough inventory or can’t meet delivery times, it may leave you having to find alternative sources at a higher cost.

5. Hidden Cost

While the initial price may be low, there may be other hidden costs. These may include higher shipping costs, reduced product packaging costs and fees for handling defective products. Over time, these hidden fees can pay for the reduced costs or even lead to financial losses and bankruptcy.

6. Lack of industrial compliance

Certain industries have strict regulations regarding the materials used in their production. Low-cost suppliers may not comply with these regulations, and all of this risk is transferred to you. This can lead to legal problems, fines, and damage to your reputation. For example, the use of substandard building materials can cause structural failure, endanger human lives, and lead to lawsuits.

7. Sustainable development issues

Many low-cost suppliers do not prioritize sustainability and use practices and materials that are harmful to the environment. This can be a significant issue for companies committed to sustainable practices, as working with such suppliers can harm your brand reputation and violate the company’s social responsibility policies.

8. Limited customization and flexibility

Standardized products often offered by low-cost suppliers. If your business requires special sizes, coatings, or custom packaging, a low-cost supplier may not be able to meet your needs. This lack of flexibility may hinder your ability to deliver a unique or high-quality product to your customers.

9. Risk of supply chain disruption

Low-cost providers may lack the financial stability and infrastructure to withstand disruptions from economic fluctuations, natural disasters, or other factors. This increases the risk of supply chain disruption, leading to production delays and increased costs, and you have to find alternative suppliers.

10. Problem-solving ability and attitude

While choosing a low-priced metal coil supplier may seem like an easy way to save money, the potential risks and hidden fees may outweigh the initial savings. When product quality problems arise, it is difficult for low-price suppliers to provide a suitable solution because they do not have sufficient technical support and financial support. Some low-price suppliers attribute all problems with their products to customers, resulting in inability to solve problems in time and irreversible losses.

While choosing a low-priced metal coil and sheet supplier may seem like an easy way to save money, the potential risks and hidden costs may outweigh the initial savings. The long-term implications of such decisions must be considered, including product quality, supply chain reliability, industry standards compliance and more. Witop Steel Group ensures consistent quality, reliable delivery and stronger, more sustainable business relationships.

When you need steel products, I suggest you prioritize and consider Witop Steel. Witop Steel is a steel manufacturer specializing in the production of galvanized Steel, galvalume steel, color-coated coils and color steel tiles. If you need to find other steel suppliers, you are welcome to contact us and we will be happy to provide you with professional help.